Vertical Straw Crusher

A straw pulverizer, vertical technology, applied in agricultural machinery and implements, agriculture, cutting equipment, etc., can solve the problem of inability to carry out material classification, and achieve the effect of large processing capacity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

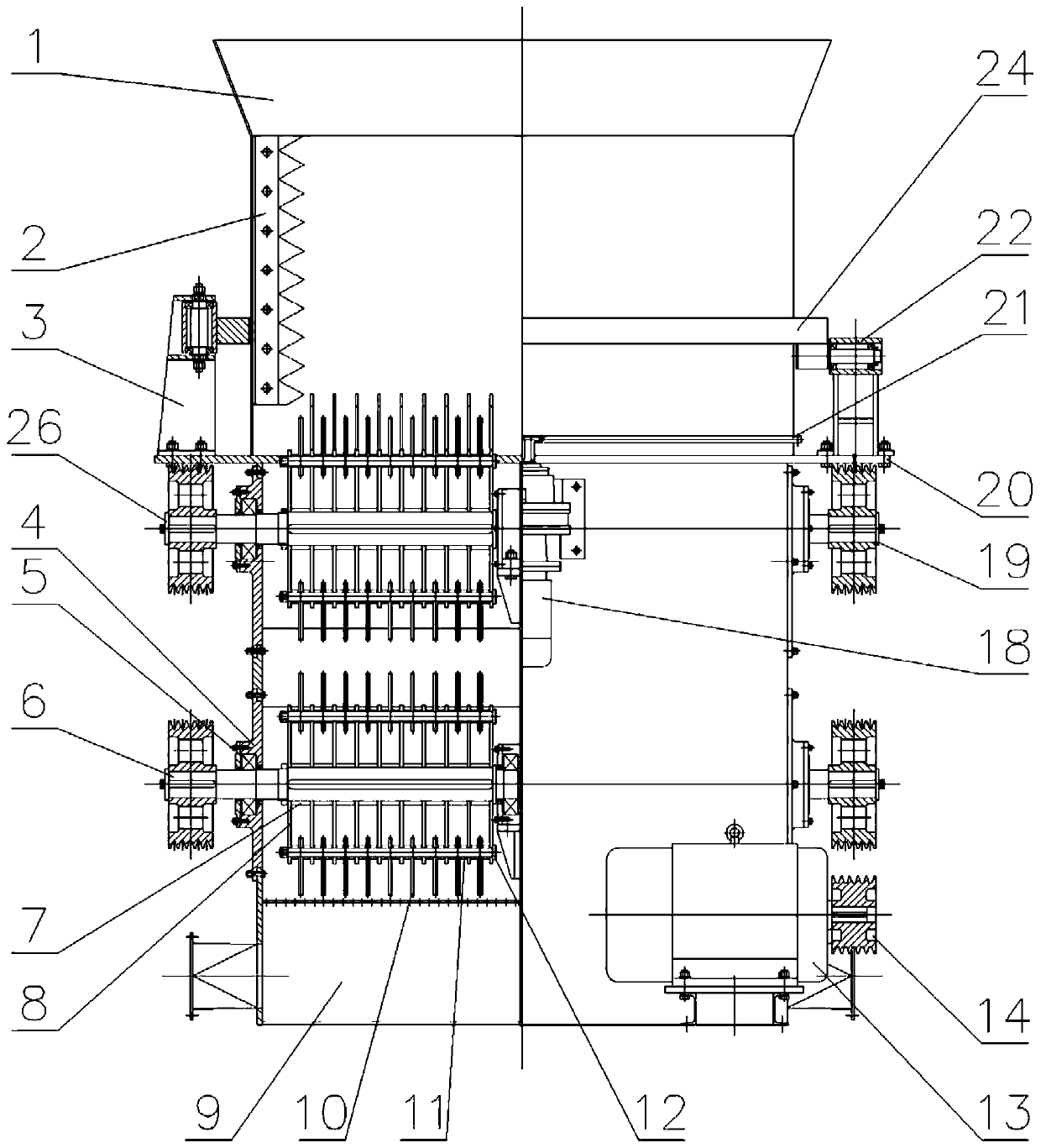

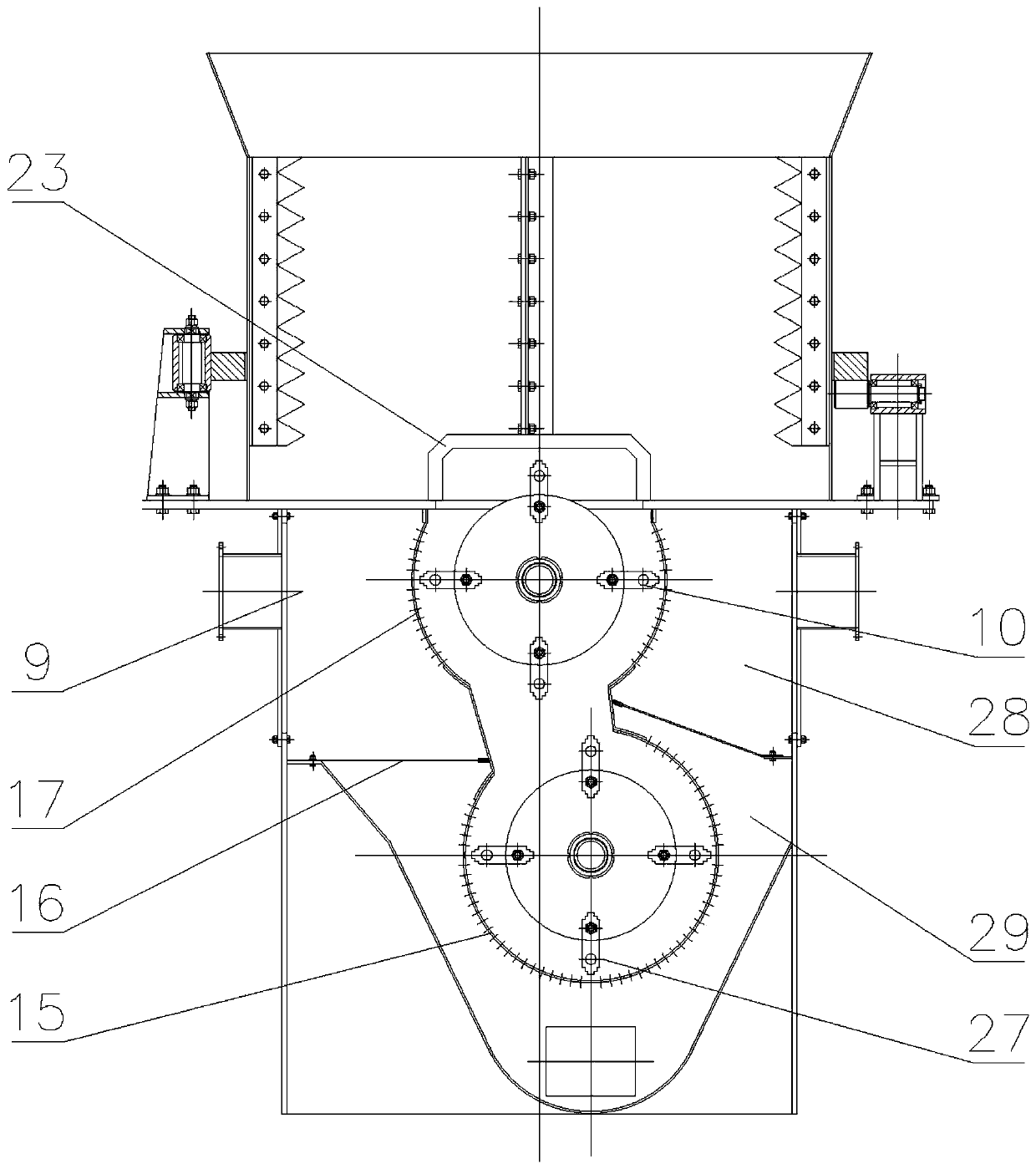

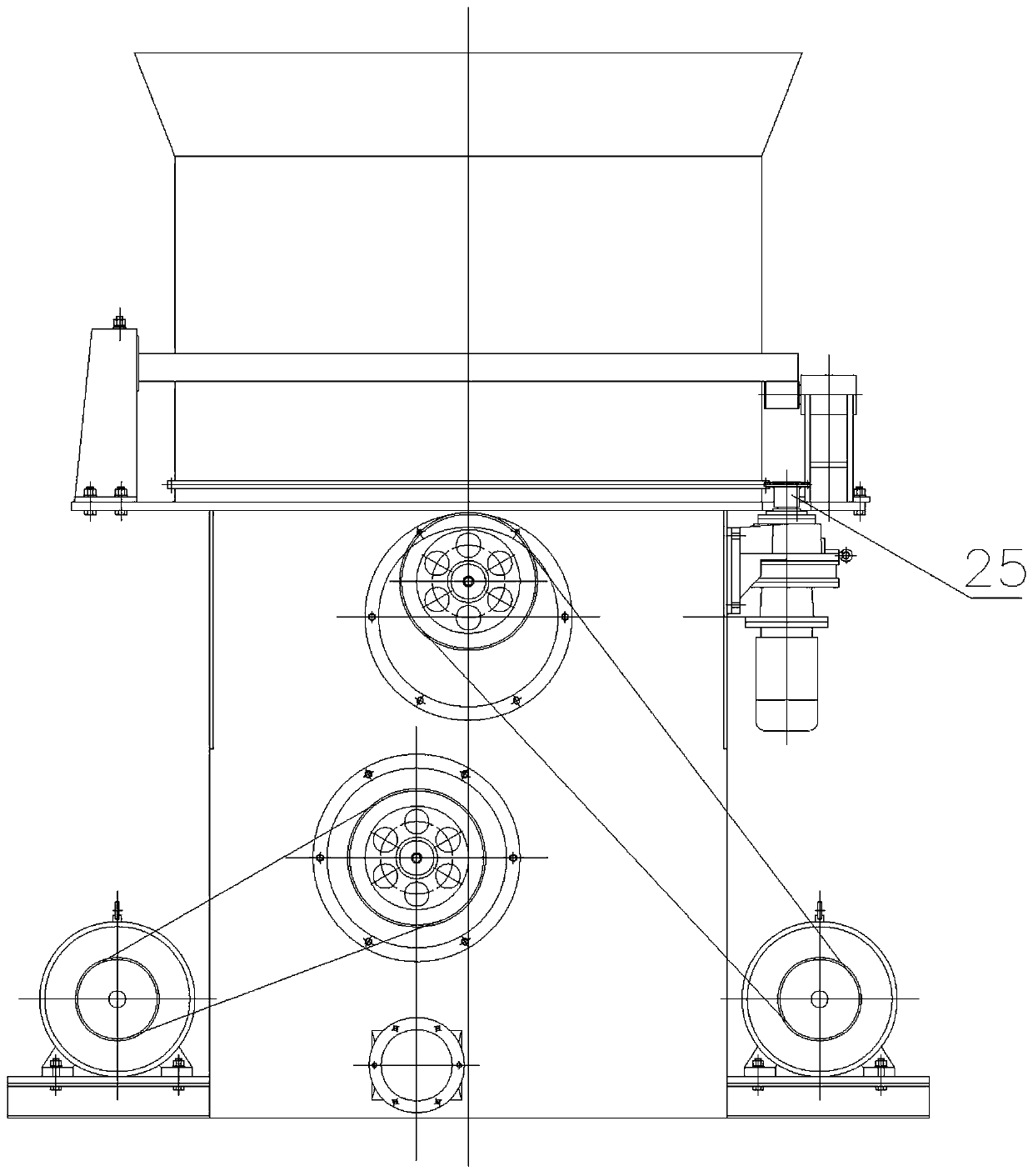

[0018] This embodiment includes a box body 9 and a drum 1; a working plate 20 is installed above the box body 9, and a first group of hammer plates 10 and a second group of hammer plates 27 are arranged in series in the box body 9; the working plate 20 An inlet 30 is provided in the middle, and a grid 23 is installed above the inlet 30; a plurality of horizontal rollers 3 and a plurality of longitudinal rollers 22 are fixed on the edge of the working plate 20. The outer side of the drum 1 is provided with a drum flange 24, and the inner wall of the drum 1 is vertically installed with a zigzag-shaped bale breaking knife 2; the lower end surface of the drum flange 24 is in contact with a plurality of longitudinal rollers 22, so the longitudinal rollers It can support the drum flange 24; a plurality of transverse rollers 3 respectively contact and cooperate with the side edges of the drum flange 24; thereby restricting the drum 1 in the horizontal direction.

[0019] A partition 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com