Bubble-scale structure-effect control model modeling method for micro-interface strengthening reactor

A model modeling and reactor technology, applied in the direction of instruments, special data processing applications, calculations, etc., can solve problems that are not structure-effect control models, reactor design has no guiding significance, and does not include reactor structural parameters, operating parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0165] This embodiment specifically illustrates the modeling method of the bubble scale model of the present invention.

[0166] The method of the present invention comprises:

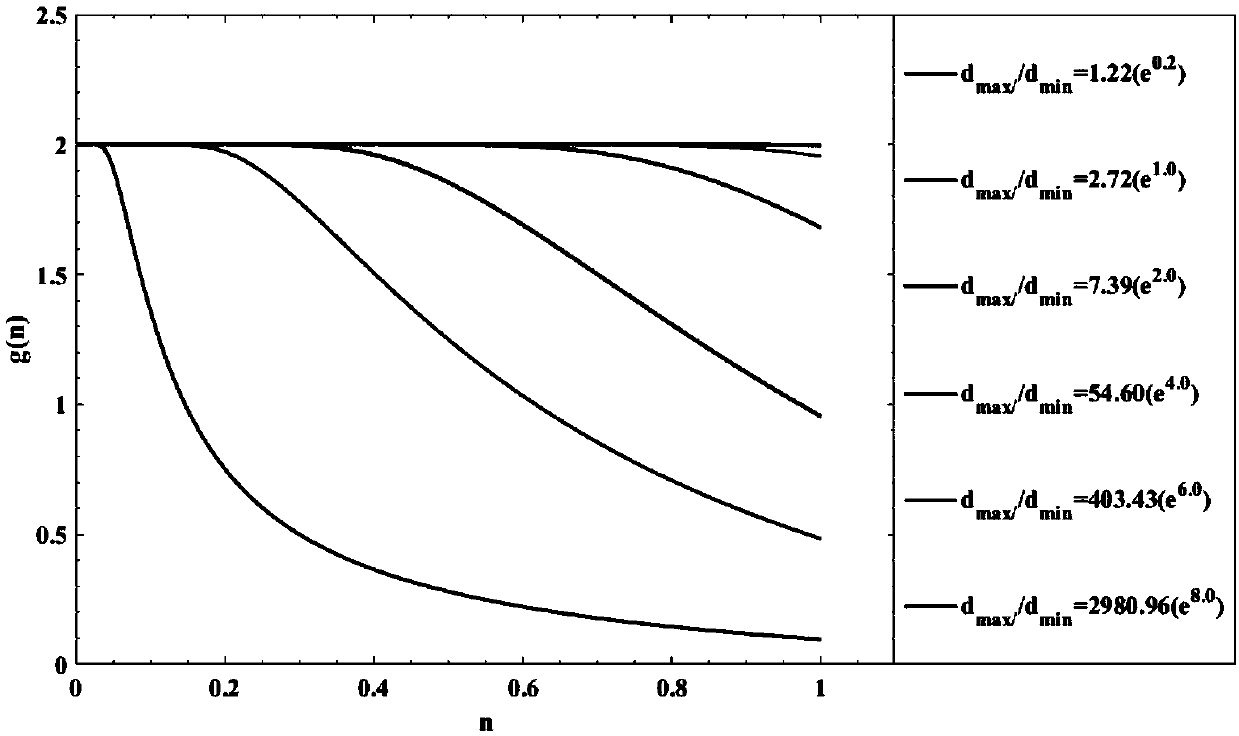

[0167] (1) The maximum bubble diameter d of the micro-interface strengthened reactor max and the minimum bubble diameter d min is the independent variable, the average Sauter diameter of bubbles d 32 As the dependent variable, establish d max 、d min and d 32 The relationship between them; the specific steps are as follows:

[0168] Let x, m, and n be the mean and standard deviation of the bubble particle size and the geometric natural logarithm of the bubble particle size in the gas-liquid system of the reactor, respectively, and obtain the probability density function of the bubble particle size x:

[0169]

[0170] Bubble Sauter average diameter d when the bubble particle size satisfies this distribution 32 for:

[0171] d 32 =exp(m+2.5n 2 ) (2)

[0172] The bubble size x is log-normall...

Embodiment 2

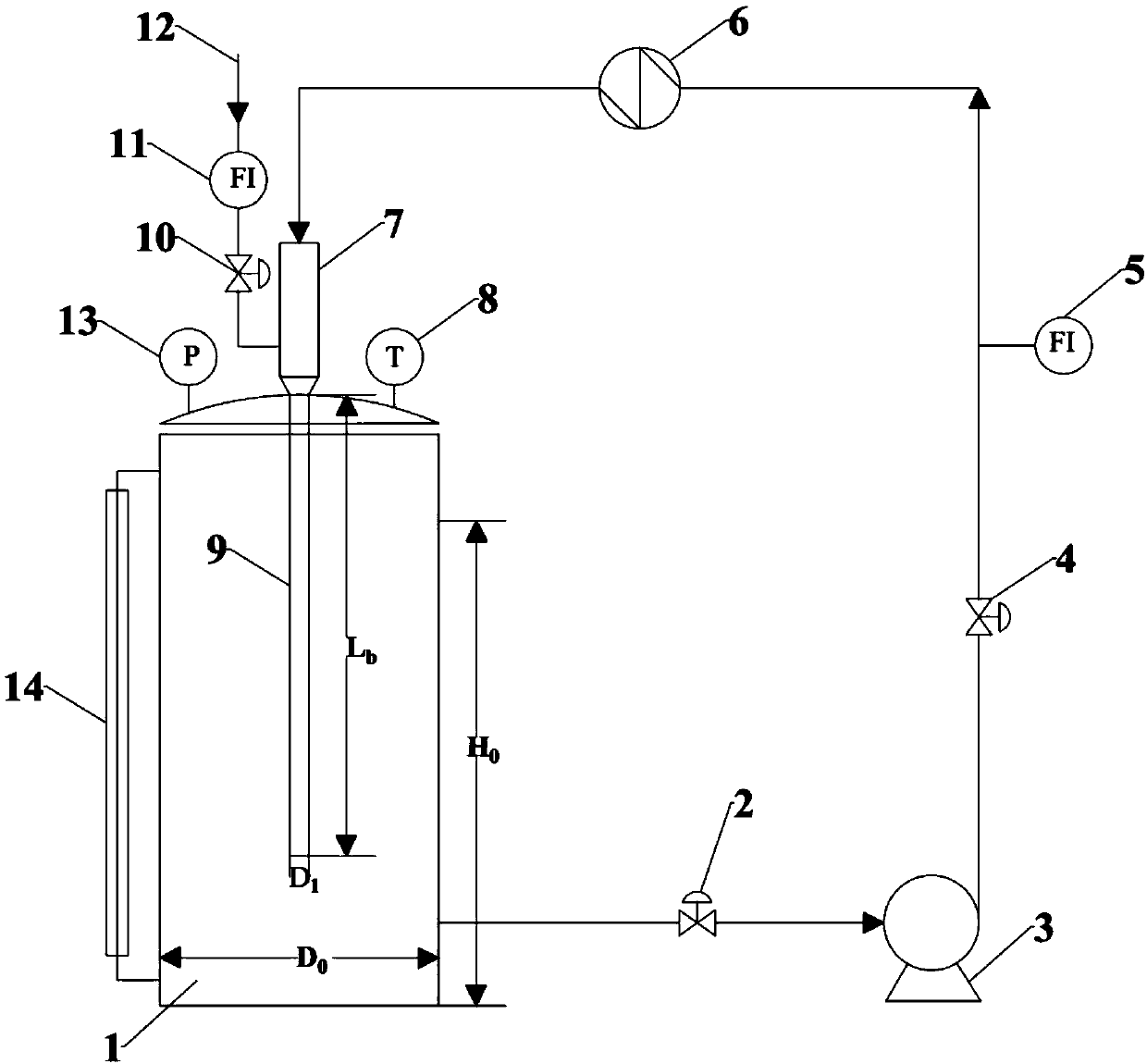

[0278] This embodiment takes figure 1 The reactor shown is taken as an example to illustrate the application of the model constructed by the modeling method described in Example 1 in the carbon dioxide and water system reactor. figure 1 The structure of the reactor can be the structure of the existing micro-interface strengthening reactor, and only the method of the present invention is used for parameter design, and the structure of the reactor is not described in detail in the present invention.

[0279] The bubble-scale structure-effect control model constructed according to Example 1 is as follows:

[0280]

[0281] d min =11.4(μ L / ρ L ) 0.75 ε -0.25 (twenty one)

[0282] d max =0.75(σ L / ρ L ) 0.6 ε -0.4 (twenty four)

[0283]

[0284]

[0285]

[0286]

[0287] In the formula, Q L is the liquid circulation volume flow rate in the reactor; L mix is the length of the bubble crushing zone; D 1 is the diameter of the bubble breaking tube; λ ...

Embodiment 3

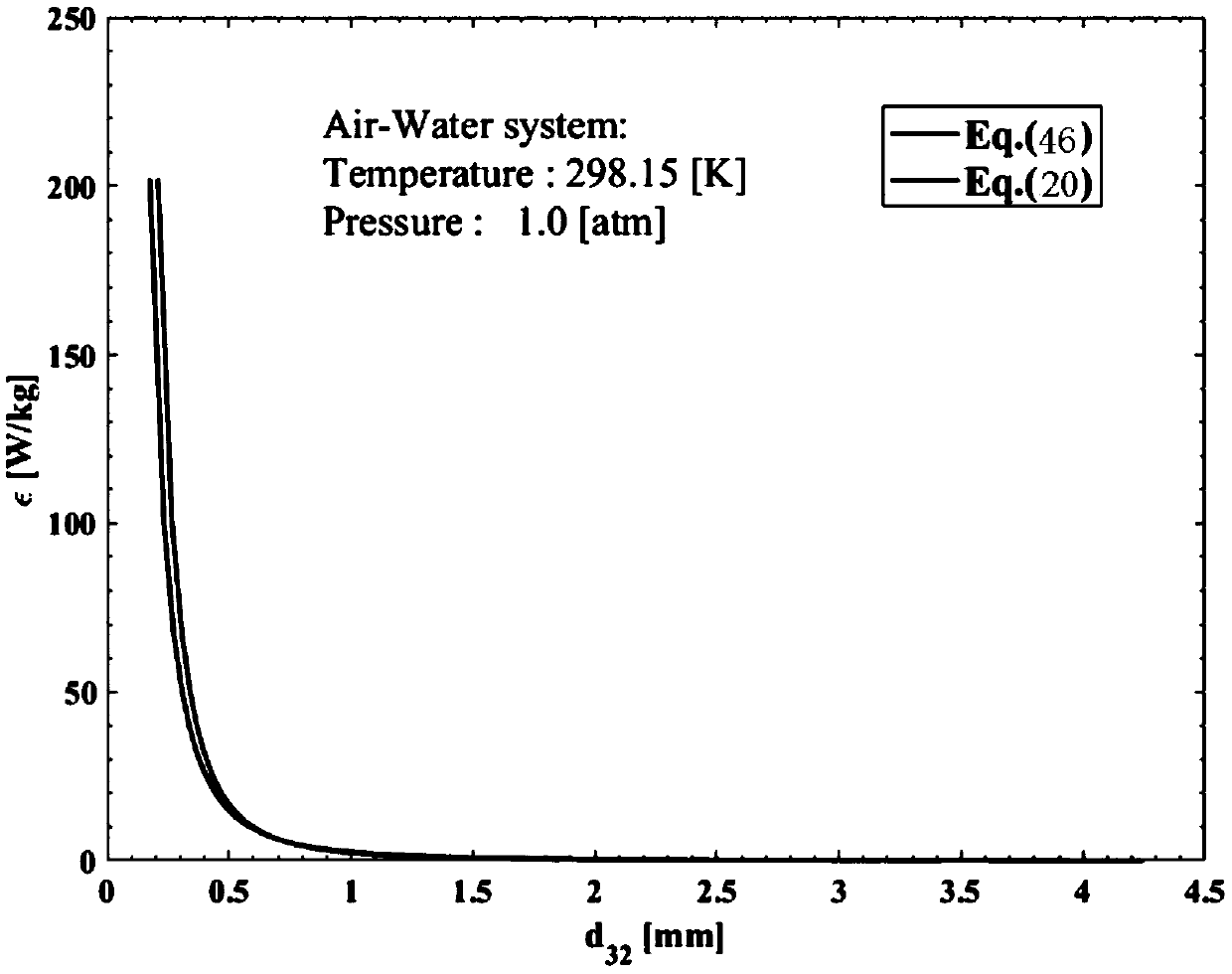

[0288] The model selected in embodiment 3 mainly considers L mix less than L b The situation, because the opposite situation is not common, more extreme. The structural parameters of the reactor also need to satisfy: λ 1 =0.1~0.5、K 1 =0.5,L b =13D 1 ;

[0289] For carbon dioxide and water system, when the operating conditions are: Q L =2000L / h(5.56×10 -4 m 3 / s), gas flow Q G =0.2Q L , T=298K, P G0 =1atm; and the physical parameters of the liquid phase in this system are: ρ L =1000kg / m 3 , μ L =8.9×10 -4 Pa s, σ L =7.197×10 -4 N / m; diameter of reactor bubble breaker tube D 1 =0.02m; E 0 Indicates the energy input by the system, that is, the rated power on the nameplate of the circulating pump, take E 0 = 1000W.

[0290] According to the operating conditions and the above model, the average diameter of bubble Sauter can be calculated d 32 =0.426mm, while the average diameter of bubbles obtained under traditional process conditions is about 1mm. It can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com