Optical fiber ultrasonic sensor with high signal to noise ratio based on polytetrafluoroethylene (PTFE) film

An ultrasonic sensor, polytetrafluoroethylene technology, applied in the direction of measuring ultrasonic/sonic/infrasonic waves, using sound waves/ultrasonic/infrasonic waves to analyze solids, instruments, etc., can solve the problems of reducing the acoustic response range, high cost, broadening, etc., and achieve improvement Ultrasonic response range, strong corrosion resistance, and the effect of improving the sideband slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

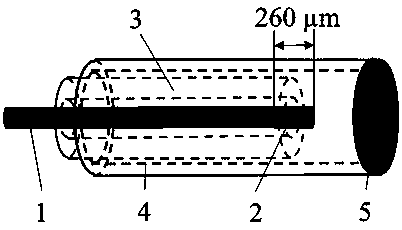

[0024] Such as figure 1 As shown, a fiber optic ultrasonic sensor with high signal-to-noise ratio based on polytetrafluoroethylene film includes a standard single-mode fiber 1, and a section of graded-index multimode fiber 2 is welded to one end of the standard single-mode fiber 1 to form a fiber collimator. The end face of the collimator and the PTFE film 5 constitute the two reflecting surfaces of the F-P interferometer. The PTFE film is used as the ultrasonic response medium. The PTFE film 5 is pasted on one end of the aluminum tube 4, and the aluminum tube 4 is provided with a organic glass tube 3 inside.

[0025] The distance between the end face of the plexiglass tube 3 and the PTFE film 5 is not less than 3mm, the optical fiber collimator penetrates into the plexiglass tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com