Condenser

A technology for condensers and condensing tubes, applied in steam/steam condensers, tubular elements, heat exchange equipment, etc., which can solve problems such as short flow time, reduced transformer performance, and high temperature, so as to improve flow time and increase Effect of diversion area and low gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a condenser.

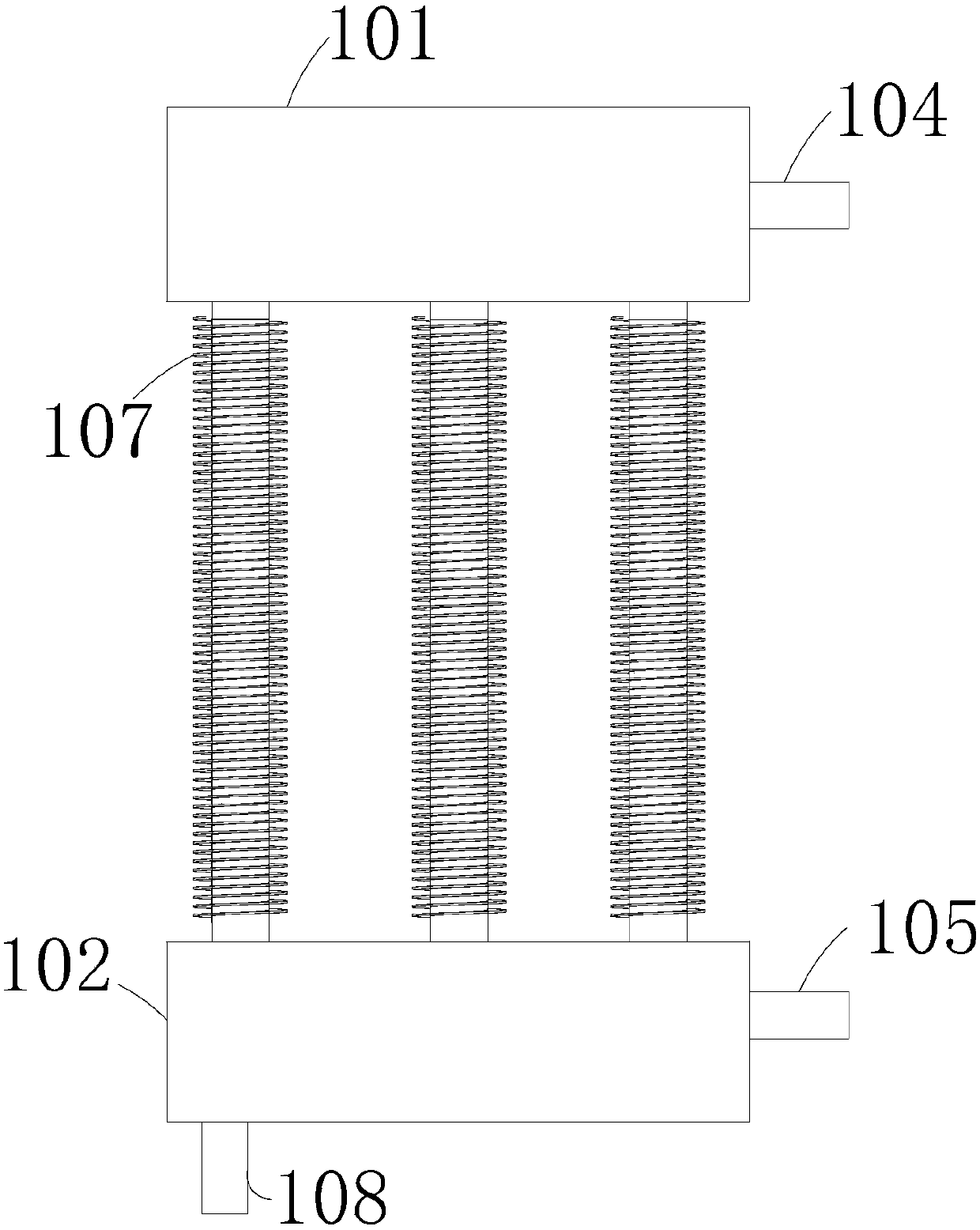

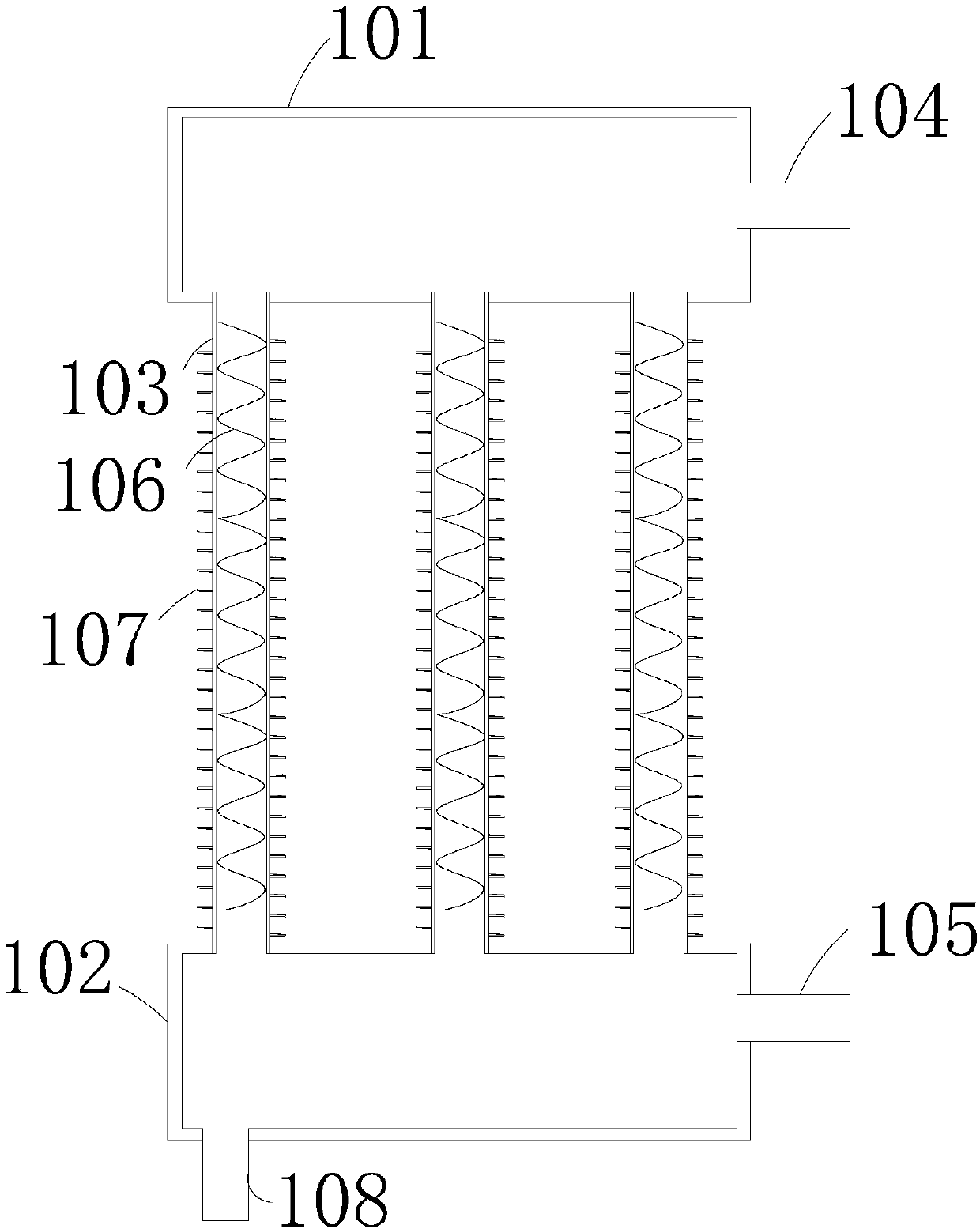

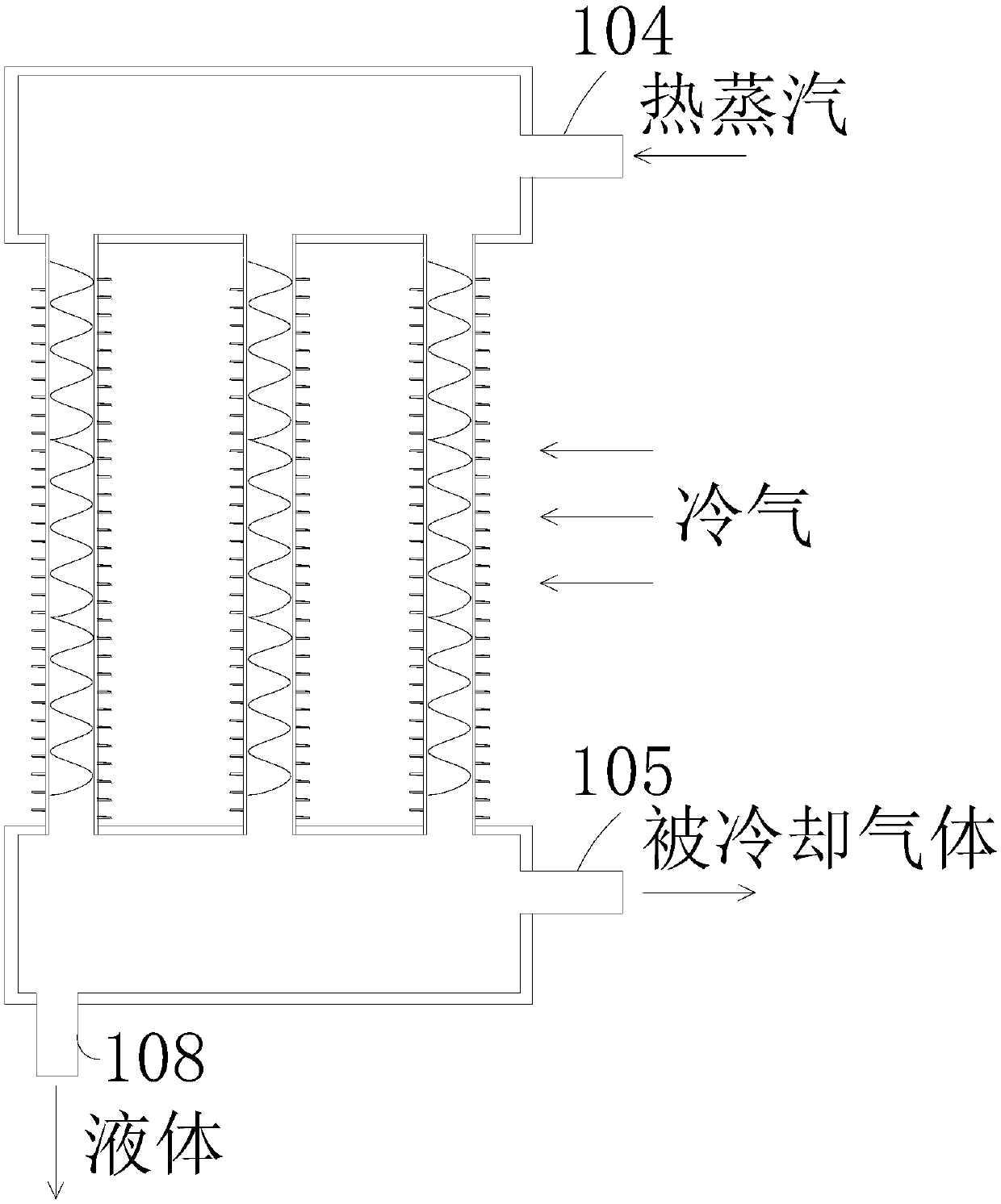

[0036] see figure 1 , this condenser includes an upper shell 101, a lower shell 102 and a condensation pipe 103, the side of the upper shell 101 is connected with an air inlet pipe 104, and the side of the lower shell 102 is connected with an air outlet pipe 105, The bottom of the lower housing 102 is provided with a liquid outflow tube 108 .

[0037] Such as figure 2 As shown, the condensing pipe 103 is connected between the upper housing 101 and the lower housing 102, the condensing pipe 103 is provided with a steel mesh cooling strip 106, and the condensing pipe 103 is provided with a condensing sheet 107, the Both the steel mesh cooling bars 106 and the condensation fins 107 are in a spiral structure and extend along the extension direction of the condensation pipe 103 . The condensing pipes 103 are arranged in parallel; all the condensing pipes 103 are provided with steel mesh cooling strips 106 .

[0038] The steel mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com