Solar heat collector

A technology of solar heat collectors and heat-absorbing fins, which is applied in the field of solar heat collectors, can solve the problems of low utilization rate of solar energy, achieve the effects of increasing heat collection, increasing heat collection power, and increasing heat collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

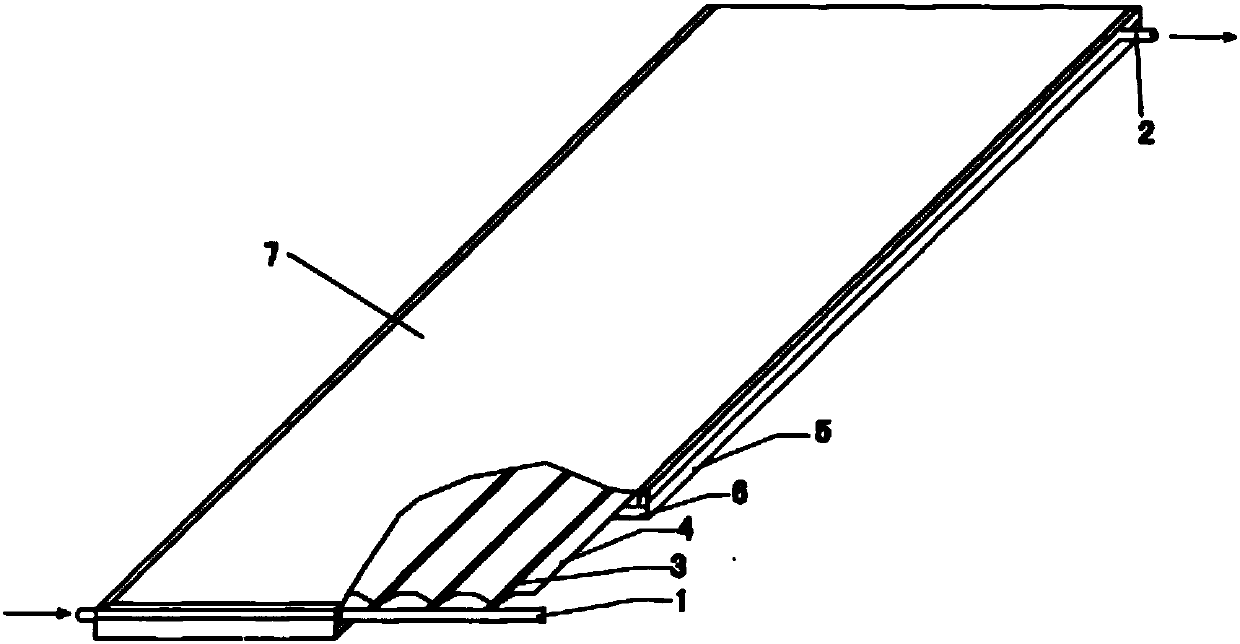

[0011] see figure 1 , figure 2 , the solar heat collector of the present invention comprises a water inlet main pipe 1, a water outlet main pipe 2, a plurality of heat transfer copper pipes 3 connected between the water inlet main pipe and the water outlet main pipe, heat-absorbing fins connected on the heat transfer copper pipes 4, and frame 5, insulation layer 6, glass cover plate 7.

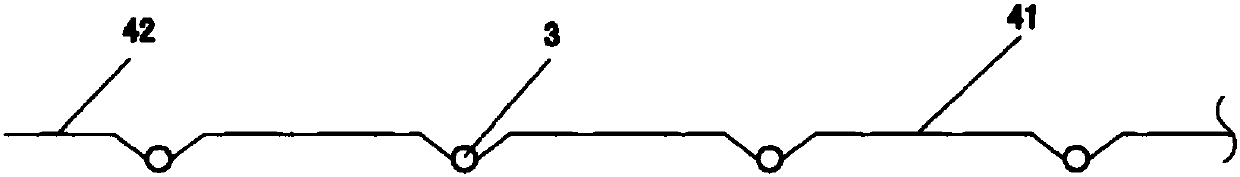

[0012] Cooperate see figure 2 , the heat-absorbing fin 4 in the present invention is a terrace-shaped heat-absorbing fin, and the terrace-shaped heat-absorbing fin is formed by pressing two aluminum alloy plates arranged on the upper and lower sides of the heat transfer copper tube through a special mold. The heat-absorbing fins wrap the heat-transfer copper tubes 3 inside, and form a terraced structure 41 between two adjacent copper tubes, and form a terraced structure 42 outside the edge copper tubes. The upper and lower sides are coated with a heat absorbing coating (not shown). Where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com