Method for preventing zinc flow lines from appearing in surface of galvanized strip steel

A strip steel and flow pattern technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems such as zinc flow lines in galvanized strip steel, improve aesthetics and reduce zinc flow lines , to avoid the effect of zinc flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

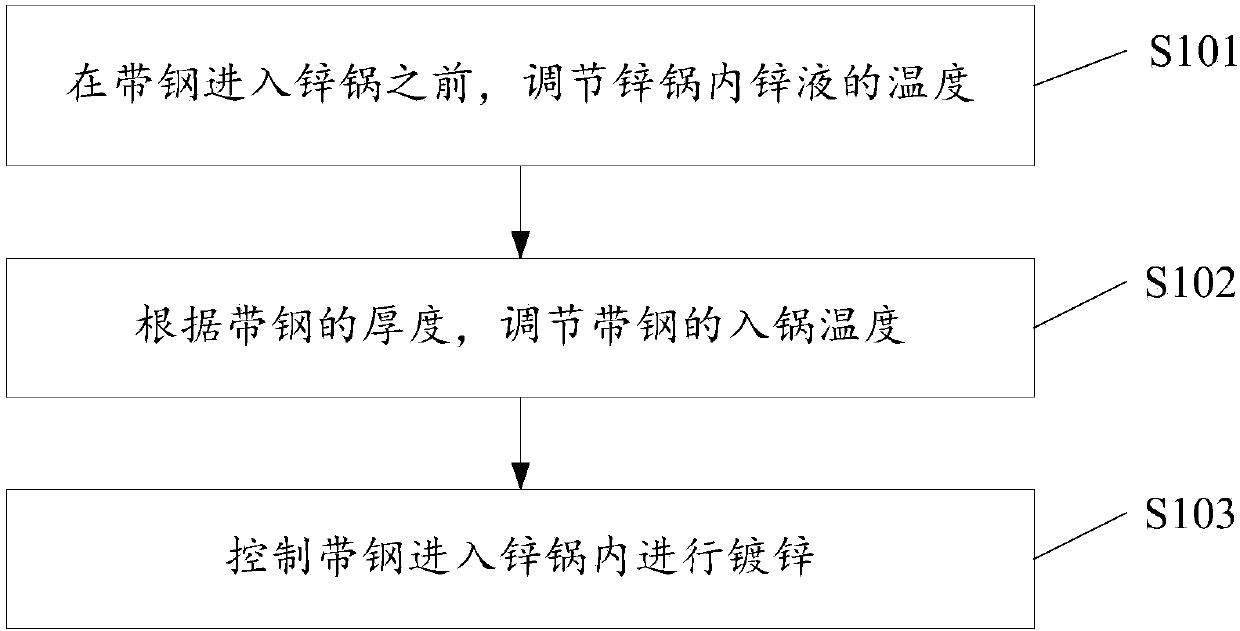

[0041] The present embodiment provides a kind of method that avoids the occurrence of zinc flow marks on the surface of galvanized steel strip, such as figure 1 shown, including:

[0042] Step S101: before the steel strip enters the zinc pot, adjust the temperature of the zinc liquid in the zinc pot.

[0043] Because the ultra-thin strip steel carries less heat before entering the zinc pot, and the cooling effect of the air knife airflow on the strip accelerates the solidification rate of the zinc liquid, resulting in obvious zinc flow defects in the ultra-thin strip steel. Since ultra-thin strip steel is mainly used for high-end home appliances after color coating, and zinc flow defects cannot be covered after color coating and affect the appearance, so it is necessary to overcome the flow defects of ultra-thin zinc.

[0044] As an optional implementation manner, step S101 includes: adjusting the temperature of the zinc liquid in the zinc pot to be 450°C-460°C.

[0045] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com