Powder-sowing and crack-making intelligent machine arm assembled on cement-based material 3D printing system

A cement-based material, 3D printing technology, applied in the direction of manipulators, instruments, additive processing, etc., to achieve the effect of stable and reliable powder spreading and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In an exemplary embodiment of the present invention, a cement-based material 3D printing device is provided. In this embodiment, the size of the printed model object is: length 3m, width 1.5m, height 1.5m, minimum unit size 6mm.

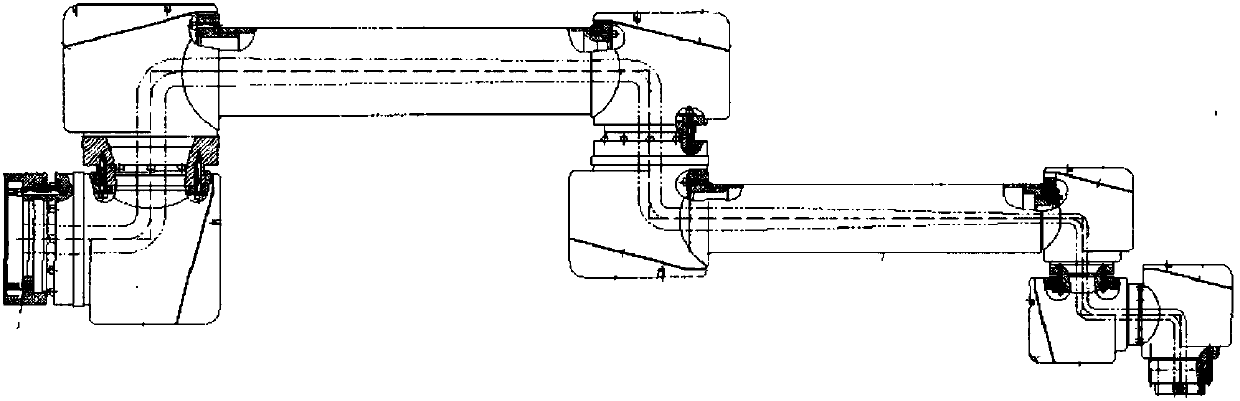

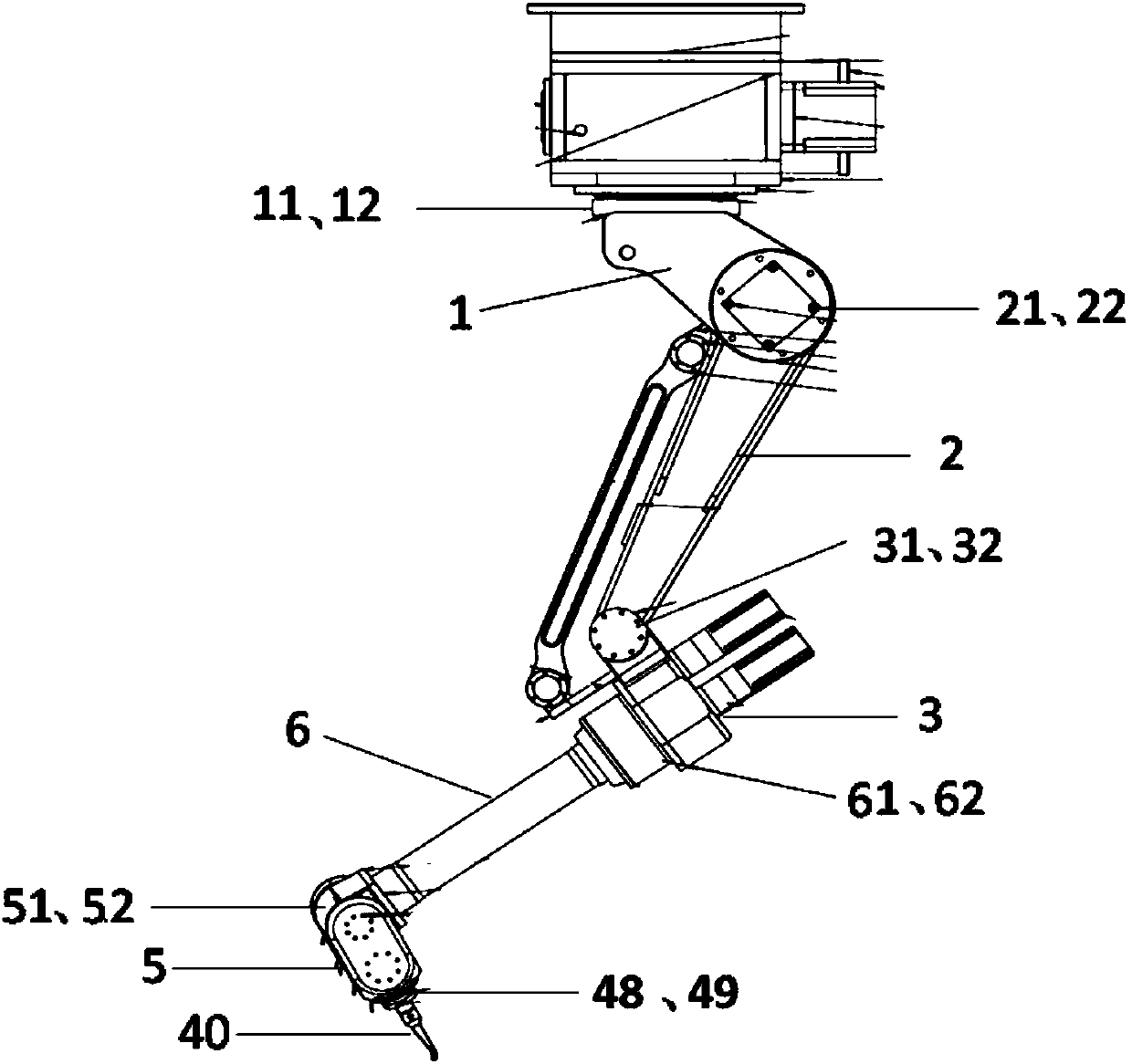

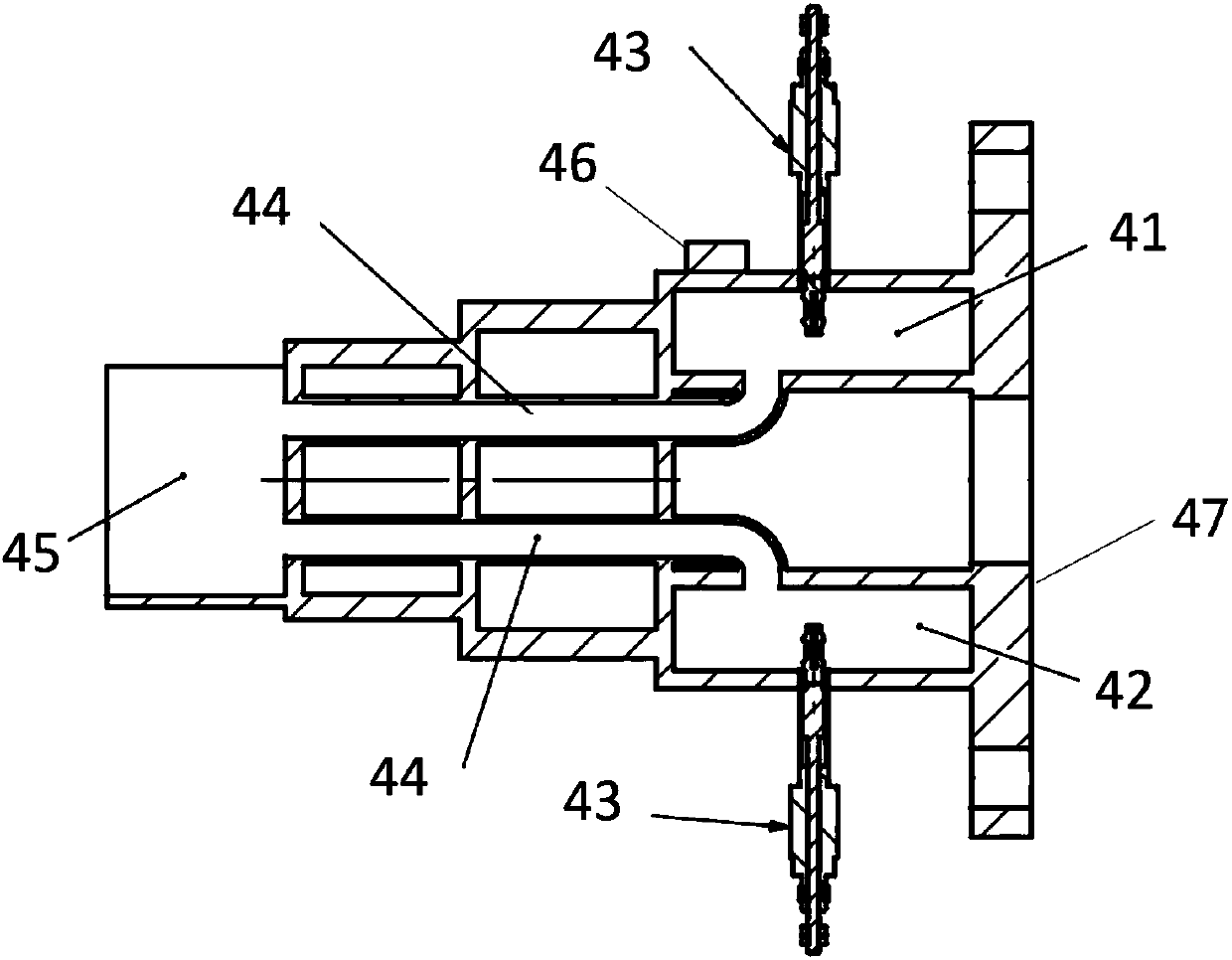

[0037] In this embodiment, the powder-spreading and cracking-making intelligent robotic hand assembled in the cement-based material 3D printing system includes: shoulder 1, big arm 2, elbow 3, forearm 6, wrist 5 and crack cutting device 4, and also includes A servo motor system composed of the first servo motor 11, the second servo motor 21, the third servo motor 31, the fourth servo motor 61, the fifth servo motor 51, and the sixth servo motor 48, a plurality of servo motors are arranged on each of the robot arms. At the joints, through the mutual rotation and cooperation of each joint, the movement and arbitrary positioning of the robot fingertip in 6 degrees of freedom in space can be realized; at the same time, it also includes the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com