Air-suction recycling type two-spray-head sand blasting machine for automobile part

A technology for auto parts and sandblasting machines, which is applied in the field of sandblasting machines, can solve the problems of polluting the air environment of equipment, sandblasting waste, etc., and achieve the goal of improving processing efficiency, reducing work efficiency, and avoiding sandblasting waste and environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

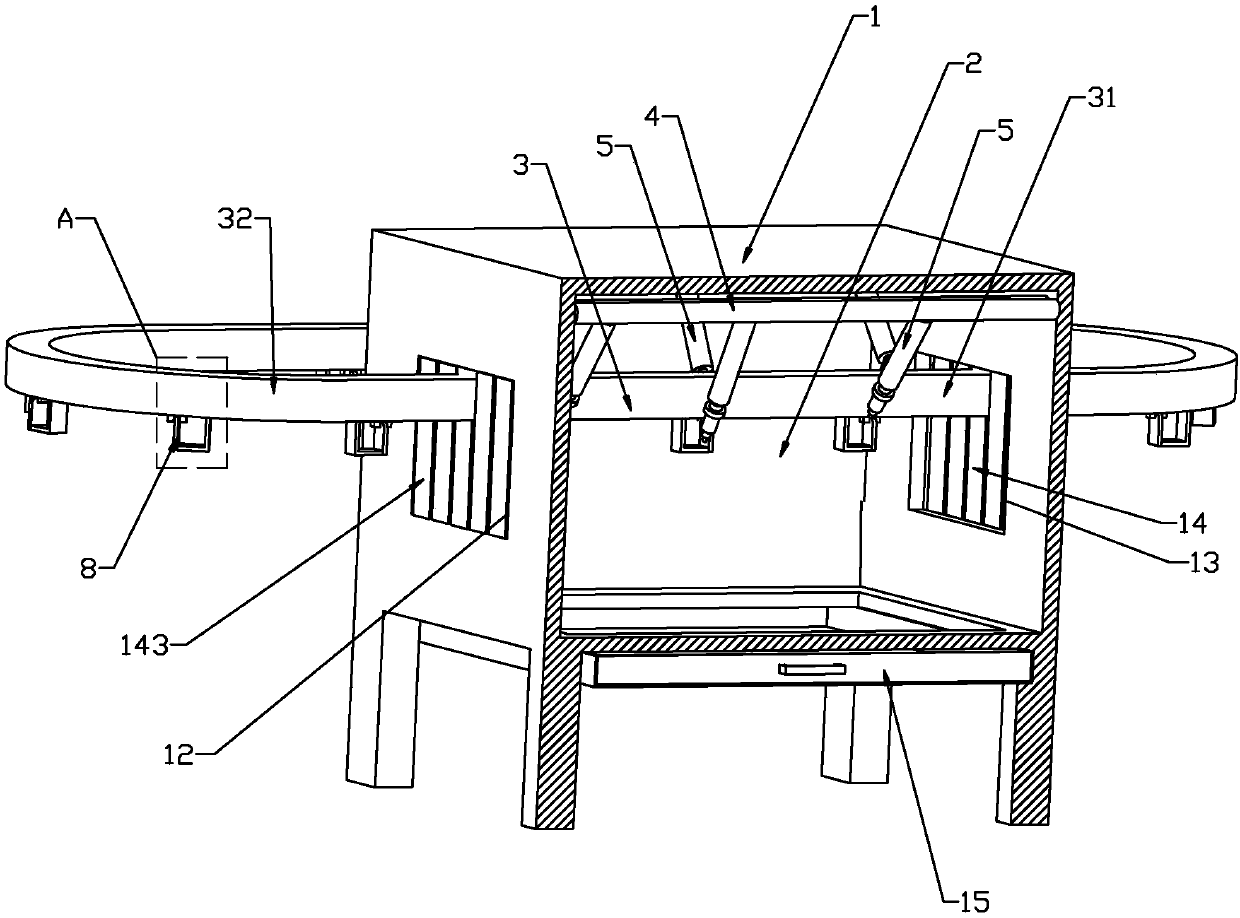

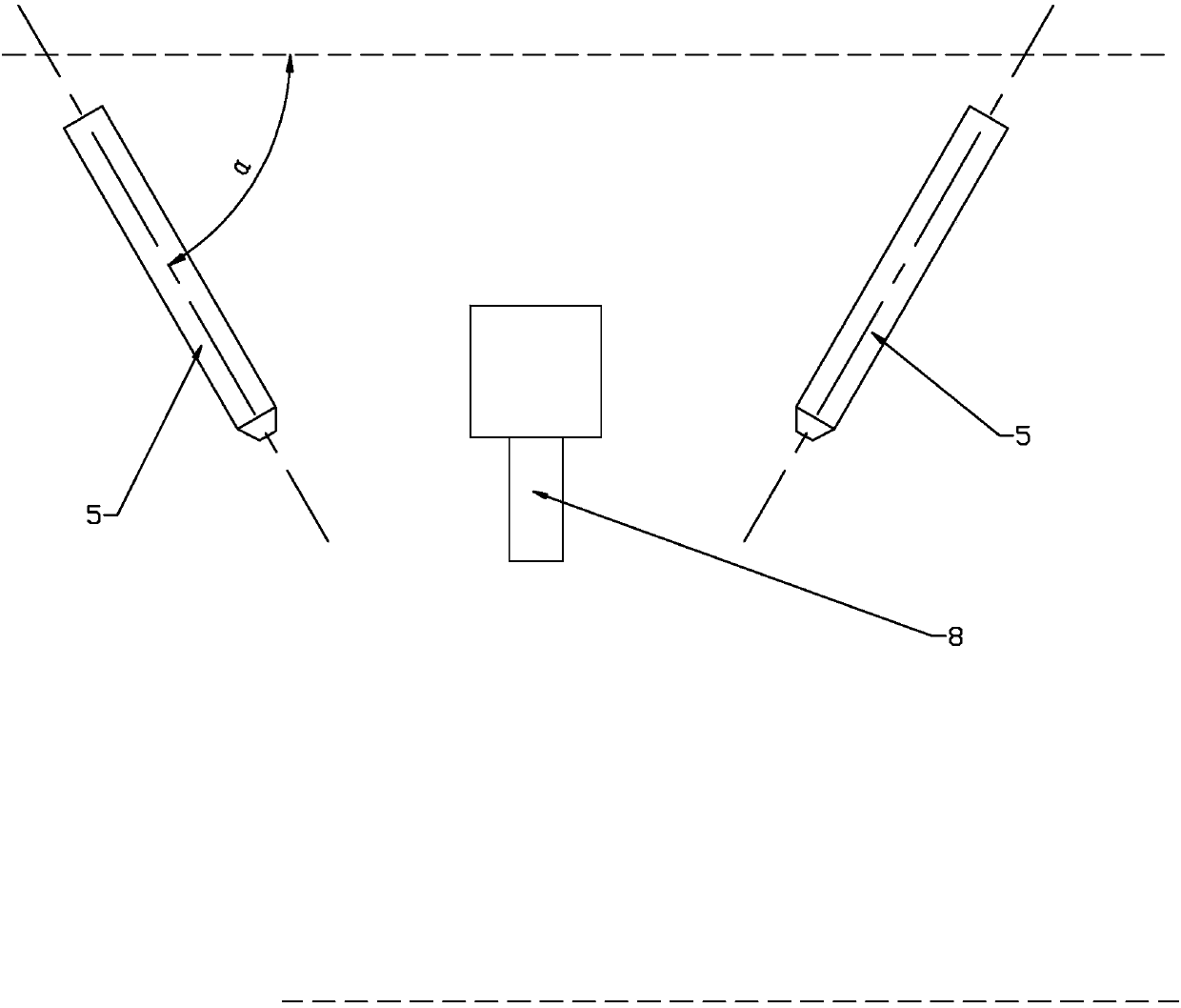

[0034] Such as figure 1 — Figure 8 As shown, the present invention discloses a sandblasting machine with two nozzles for suction and recycling automobile parts, which includes a shell 1, a sandblasting chamber 2 and a sandblasting device are arranged in the shell 1, and a circulation transmission device, a circulation transmission device It includes an endless conveyor belt 3 and a circular drive mechanism that drives the endless conveyor belt 3 to circulate. The endless conveyor belt 3 is provided with a clamp 8 for installing automotive parts with holes. The housing 1 is provided with a feed port 12 for the endless conveyor belt 3 to enter and exit. The discharge port 13 and the endless conveyor belt 3 are provided with a component processing section 31 located inside the housing 1 and a component disassembly section 32 located outside the housing 1, and the housing 1 is located at the feed port 12 and the discharge port 13 respectively. There is a sandblasting recovery bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com