A kind of three-dimensional abrasive and its preparation method

An abrasive, three-dimensional technology, applied in abrasives, chemical instruments and methods, grinding/polishing equipment, etc., to achieve the effect of reducing the frequency of replacing abrasive consumables, increasing the amount of removal, and reducing the amount of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

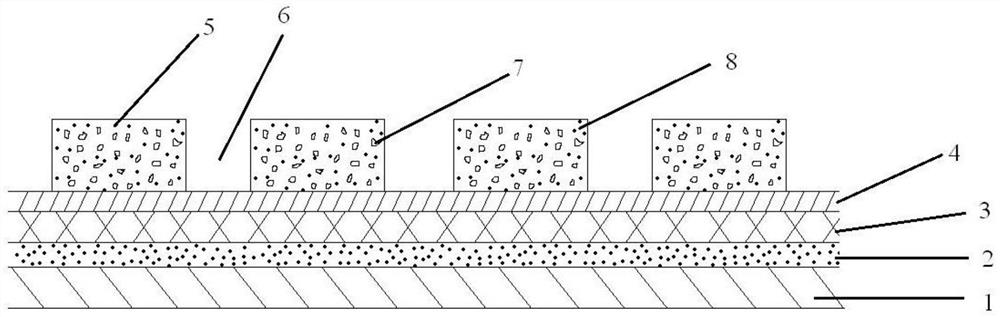

[0038] Provide semi-finished products including PC board substrate, hot melt adhesive layer, PET substrate and hot melt adhesive primer layer;

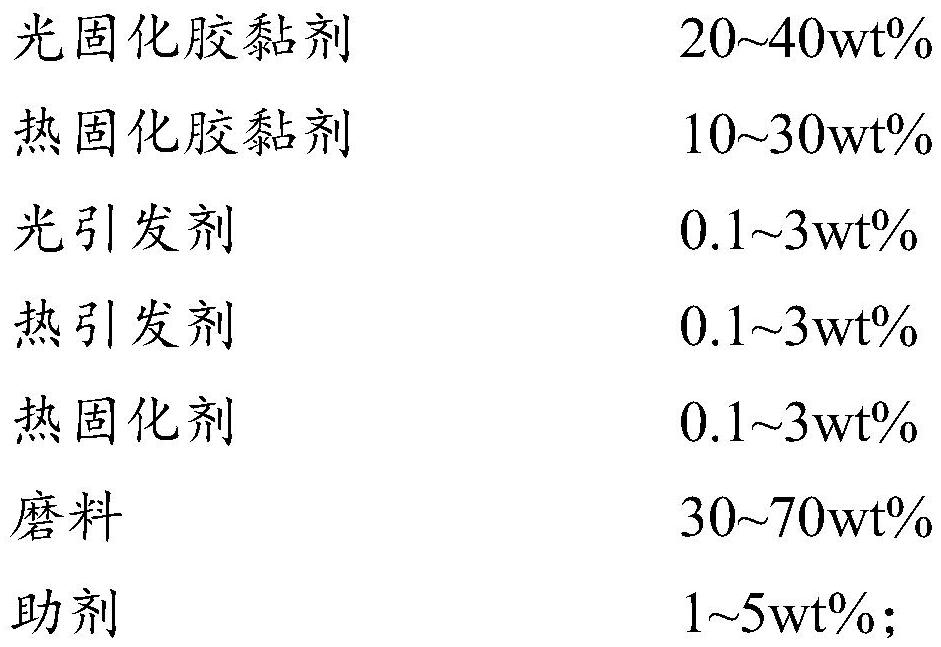

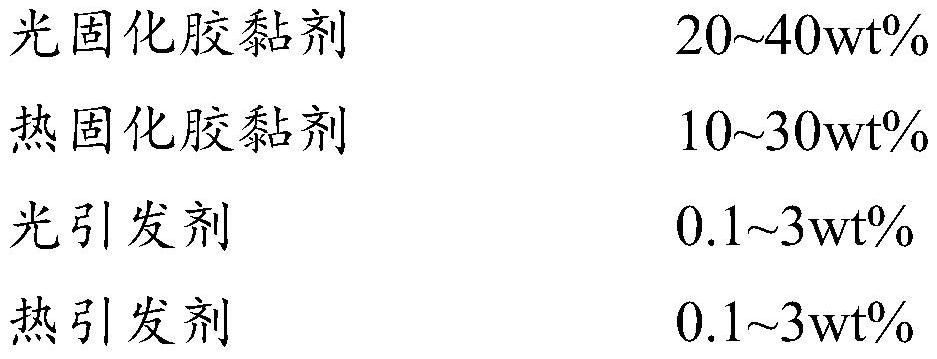

[0039] Mix the materials in the formula shown in Table 1, and disperse them in the dark by ultrasonic to form a slurry;

[0040] The dispersed slurry is placed in a concave structure mold with a certain regular arrangement by roller coating;

[0041] Attach the primer layer of the above-mentioned semi-finished product to the mold, and irradiate it with ultraviolet light, so that the slurry is cured and transferred to the substrate to form a repeatedly arranged grinding block structure;

[0042] The molded product is heated and solidified to obtain an abrasive product with a three-dimensional structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com