3C1B equipment and modification method of 3C1B equipment by adopting 3C2B equipment

A 3C1B, equipment technology, applied in spraying devices, devices for coating liquid on the surface, spray booths, etc., can solve the problems of lengthy process, poor compatibility, unnecessary, etc., and achieve the goal of shortening the stoppage period, reducing consumption and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

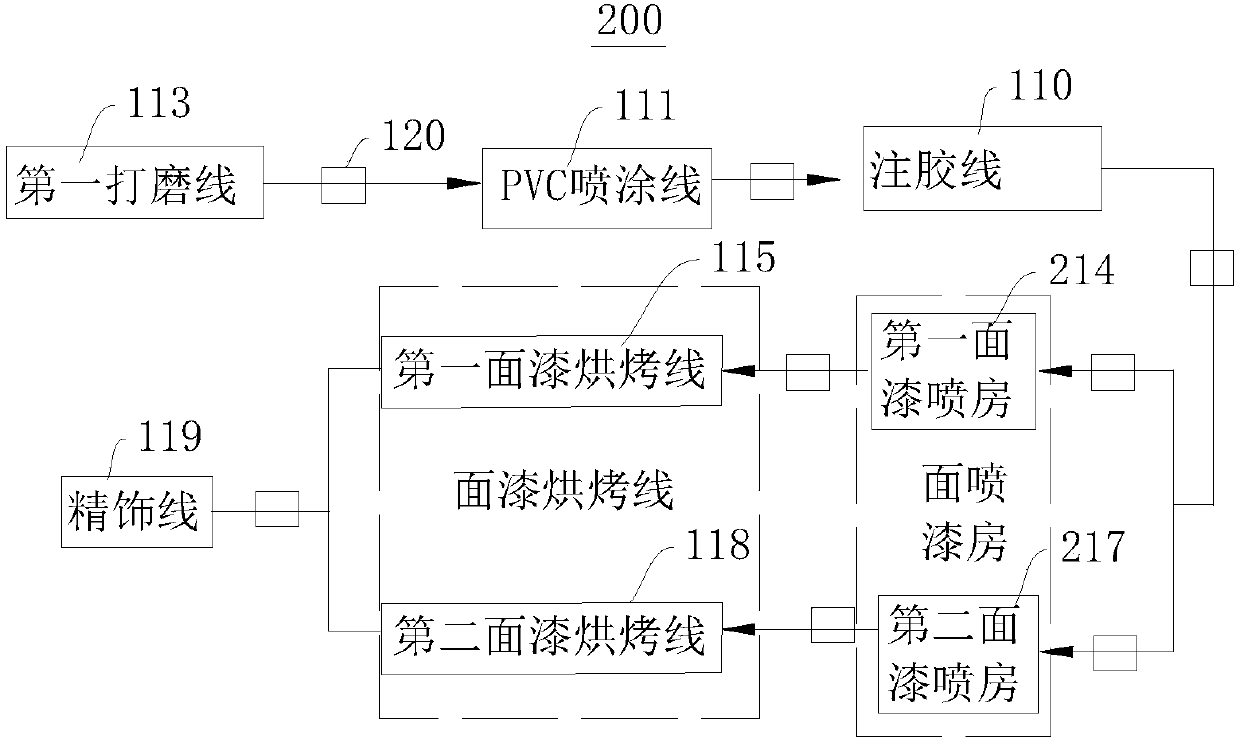

[0029] see figure 2 , the embodiment of the present invention provides a kind of 3C1B equipment, this 3C1B equipment comprises mobile equipment 120 and the following stations: first grinding line 113, PVC spraying line 111, glue injection line 110 and topcoat equipment, topcoat equipment includes surface Paint spraying booths, topcoat baking lines and finishing lines119. A mobile device 120 is arranged between each station, so that each station is connected in sequence, and driven by the mobile device 120, the automobile can enter each station in turn.

[0030] The top paint spray booth comprises a first top paint spray booth 214 and a second top paint spray booth 217, and the top paint baking line includes a first top paint baking line 115 and a second top paint baking line 118, and the first top paint spray booth The room 214 is connected to the first top paint baking line 115 , and the second top paint spray booth 217 is connected to the second top paint baking line 118 ....

Embodiment 2

[0039] This embodiment provides a method for refitting a 3C2B device 100 into a 3C1B device 200 .

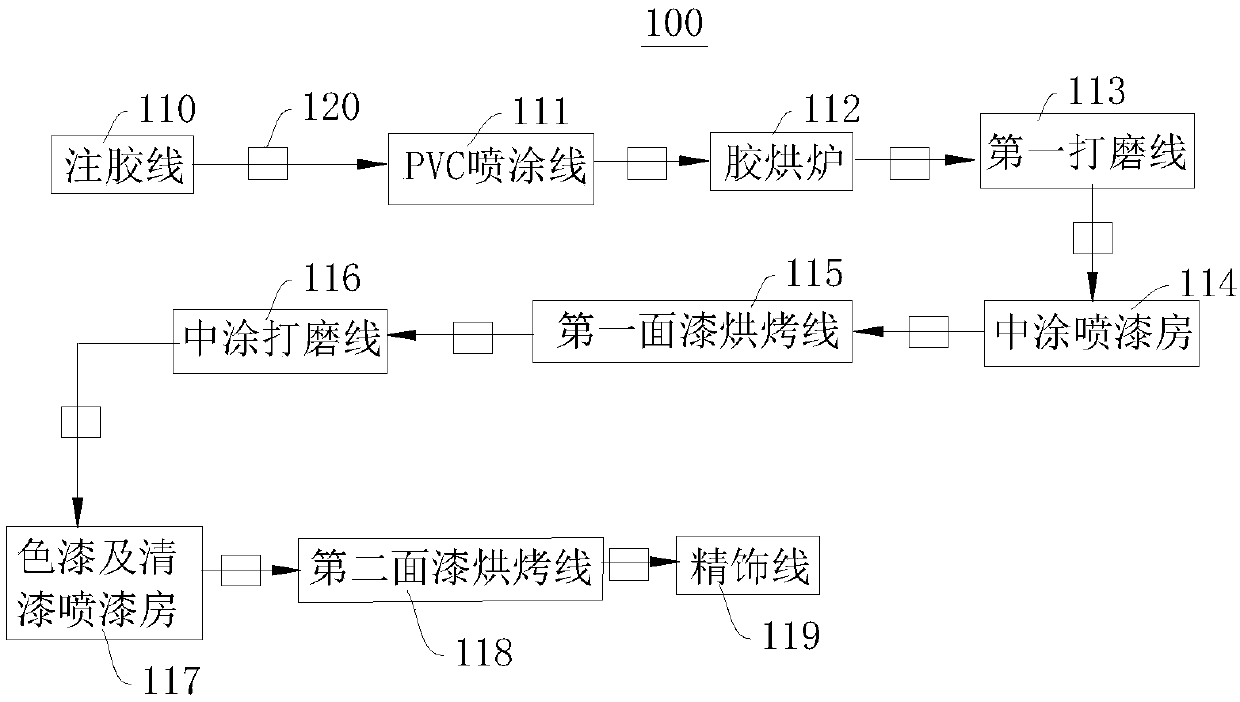

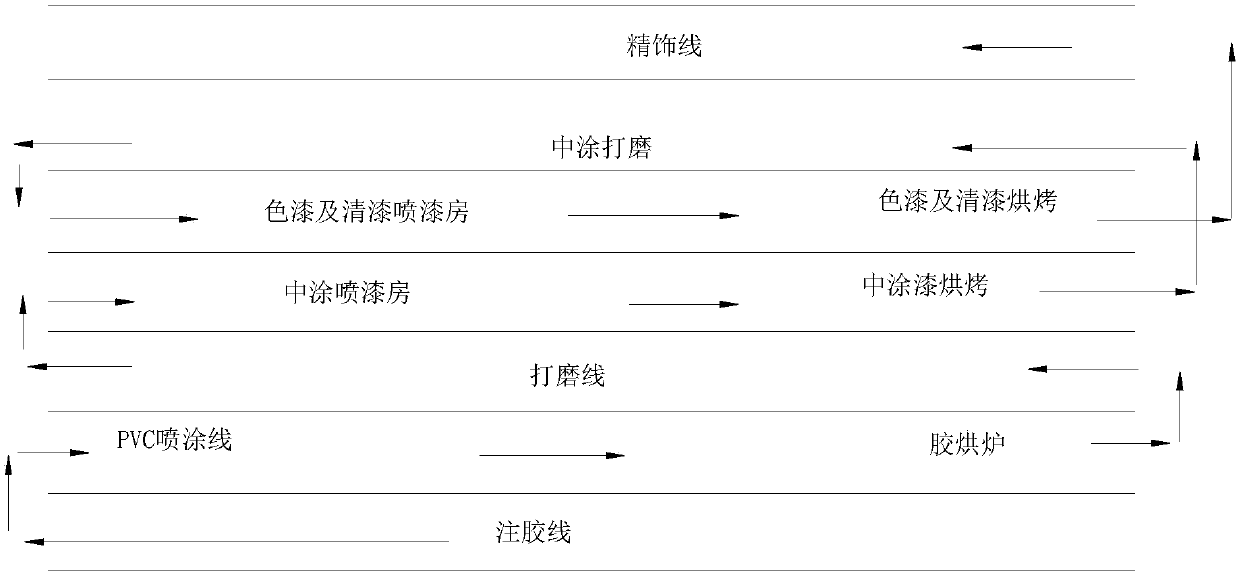

[0040] see figure 1 , the 3C2B equipment 100 before modification includes mobile equipment 120 and the following stations: glue injection line 110, PVC spraying line 111, glue oven 112, first grinding line 113 and topcoat equipment, and the topcoat equipment includes midway spray booth 114 in turn , the first top paint baking line 115, the intermediate coating grinding line 116, the color paint and varnish spray booth 117, the second top paint baking line 118 and the fine decoration line 119. There are mobile devices 120 between each station, so that each The stations are connected in turn, and the cars can enter each station in turn.

[0041] Intermediate coating equipment is included in the midway painting room 114 , and color painting equipment and varnish equipment are included in the color paint and varnish spraying room 117 .

[0042] During modification, perform the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com