A method for integrating dry process cement kiln flue gas desulfurization and denitrification

A technology of desulfurization and denitrification, dry process cement, applied in the direction of chemical instruments and methods, separation methods, air quality improvement, etc., can solve the surrounding environmental pollution, serious problems, etc., achieve significant environmental benefits, increase absorption rate, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

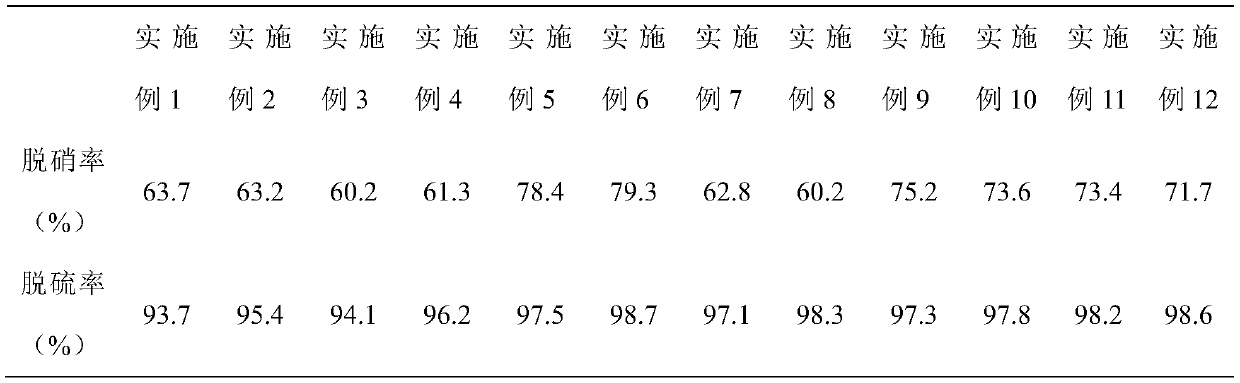

Embodiment 1

[0026] The flue gas conditions are 1000ppmNO, 2000ppmSO 2 , 1% O 2 , N 2 To balance the gas, the total gas flow rate is 900ml / min and the temperature condition is 800℃. Rice husk ash and calcium carbide slag are mixed uniformly in a volume ratio of 9:1 and then added to a tube furnace with a diameter of 3cm. The denitration rate reaches 63.7%, the desulfurization rate reached 93.7%.

Embodiment 2

[0028] The flue gas conditions are 1000ppmNO, 2000ppmSO 2 , 1% O 2 , N 2 To balance the gas, the total gas flow rate is 900ml / min and the temperature condition is 900℃. Rice husk ash and calcium carbide slag are mixed uniformly in a volume ratio of 9:1 and then added to a tube furnace with a diameter of 3cm. The denitration rate reaches 63.2%, the desulfurization rate reaches 95.4%.

Embodiment 3

[0030] The flue gas conditions are 1000ppmNO, 2000ppmSO 2 , 1% O 2 , N 2 To balance the gas, the total gas flow rate is 900ml / min, and the temperature condition is 800℃. Rice husk ash and calcium carbide slag are mixed uniformly in a volume ratio of 6:1 and then added to a tube furnace with a diameter of 3cm. The denitration rate reaches 60.2%, the desulfurization rate reaches 94.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com