Preparation method of double-layer type water-proof, anti-bacterial and anti-cicatricial chitosan sponge dressing

A chitosan, double-layer technology, applied in the application field of biomedical materials, can solve the problems of limited protection, difficulty in promoting wound repair, secondary damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

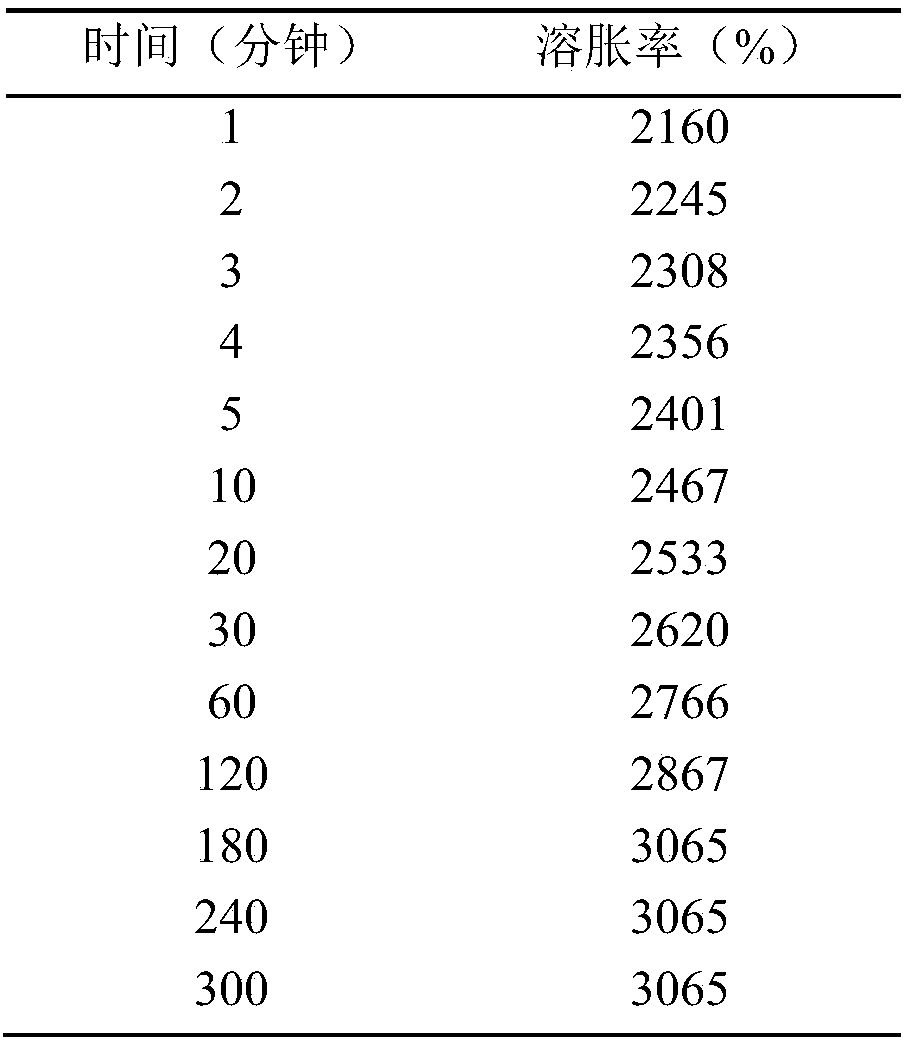

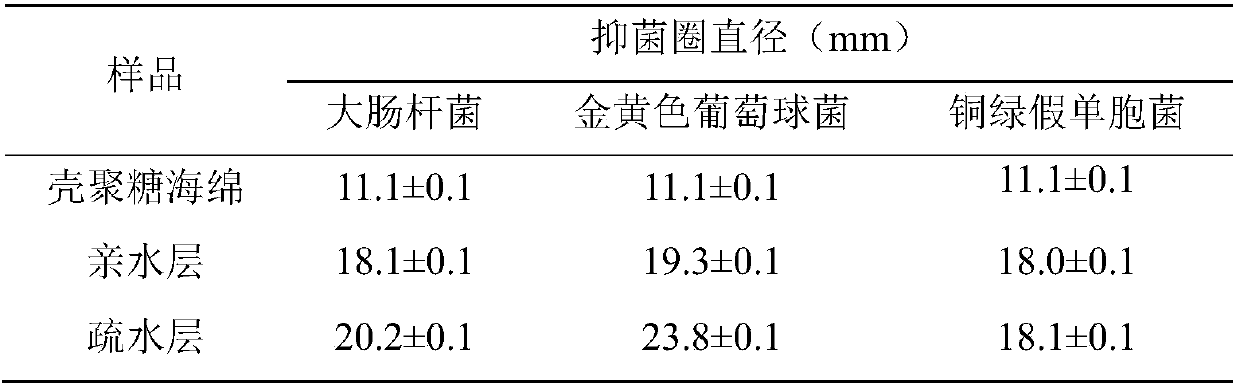

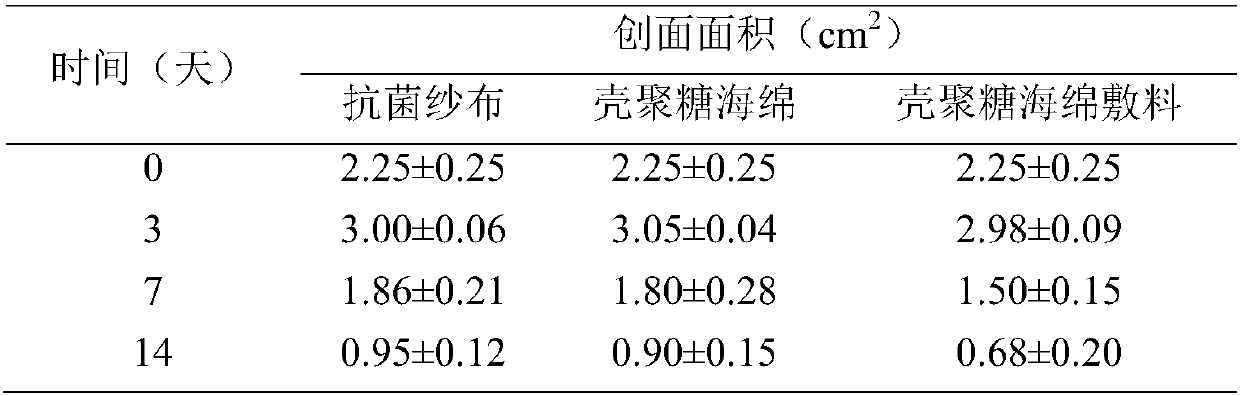

[0013] First, 3 g of molecular weight 1 × 10 4 Da, the chitosan that deacetylation degree is 80% is dissolved in the acetic acid solution that 300mL volume ratio concentration is 1% (v / v), packs into mold and adds 4mL volume ratio concentration and is 2% (v / v) pentadiene Aldehydes were cross-linked at 35°C for 1 hour to obtain a chitosan hydrogel with a cross-linking degree of 10%, soaked in deionized water, rinsed, and lyophilized after removing acetic acid and excess glutaraldehyde to obtain a chitosan sponge. Then soak half of the sponge with 200mL mass volume ratio concentration of 0.03% (w / v) ethanol solution of lauric acid for 1 hour, dry to form a hydrophobic layer, and the other half of the sponge with 200mL mass volume ratio concentration of 10% (w / v) Soak in the glucosamine aqueous solution for 2 hours, freeze-dry to form a hydrophilic layer, and make a double-layer chitosan sponge dressing after sterilization.

Embodiment 2

[0015] First, 9 g of molecular weight 5 × 10 5 Da, the chitosan that the degree of deacetylation is 70% is dissolved in the acetic acid solution that 300mL volume ratio concentration is 2% (v / v), packs into mold and adds 40mL volume ratio concentration and is 1% (v / v) epoxy resin Chloropropane was cross-linked at 20°C for 3 hours to obtain a chitosan hydrogel with a cross-linking degree of 20%, soaked in deionized water, rinsed, and lyophilized after removing acetic acid and excess epichlorohydrin to obtain chitosan Sponges, then soak half of the sponges with 200mL mass-volume concentration of 0.01% (w / v) stearic acid ethanol solution for 1 hour, dry to form a hydrophobic layer, and the other half of the sponges with 200mL mass-volume concentration of 20% (w / v) / v) soaked in glucosamine aqueous solution for 1 hour, freeze-dried to form a hydrophilic layer, and made a double-layer chitosan sponge dressing after sterilization.

Embodiment 3

[0017] First, 5g of molecular weight is 1×10 5 Da, deacetylation degree is that the chitosan of 85% is dissolved in the acetic acid solution that 300mL volume ratio concentration is 3% (v / v), packs into mold and adds 5mL mass volume ratio concentration and is 10% (w / v) three Sodium polyphosphate was cross-linked at 15°C for 2 hours to obtain a chitosan hydrogel with a cross-linking degree of 10%, soaked in deionized water, rinsed, and lyophilized after removing acetic acid and excess sodium tripolyphosphate to obtain chitosan hydrogel. Sugar sponge, soak half of the sponge with 200mL mass-volume concentration of 0.05% (w / v) palmitic acid ethanol solution for 3 hours, dry to form a hydrophobic layer, and the other half of the sponge with 200mL mass-volume concentration of 30% (w / v) / v) soaked in glucosamine aqueous solution for 2 hours, freeze-dried to form a hydrophilic layer, and made a double-layer chitosan sponge dressing after sterilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com