Antimony selenide thin film solar cell and preparation method thereof

A technology of solar cells and antimony selenide, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as endangering human health, environmental pollution, and unstable device performance, and achieve improved photocurrent, stable chemical properties, and improved stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The first step is to use ultrasonic cleaning method to ultrasonically clean ITO or FTO glass according to the following steps, each step is 30 minutes, and the heating temperature is 20-50°C: detergent + deionized water, acetone, isopropanol, ethanol, deionized water . After cleaning, blow dry with nitrogen.

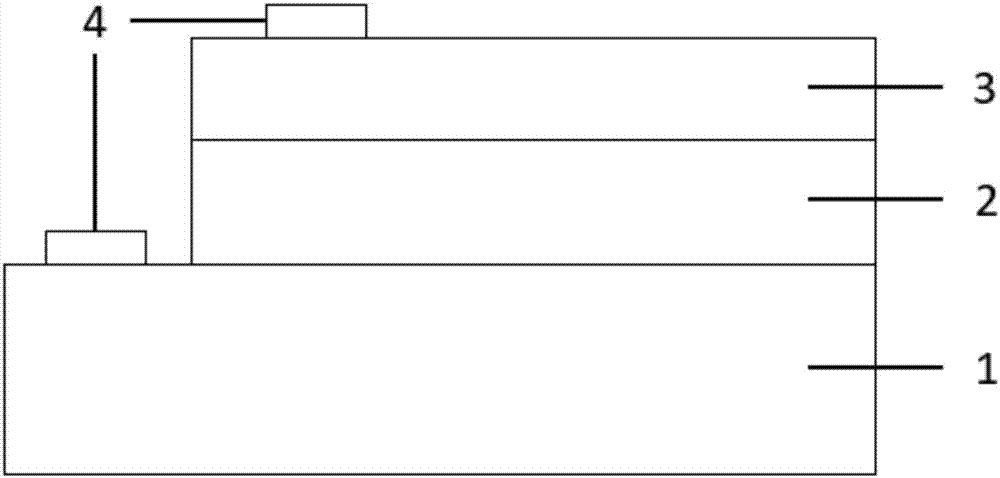

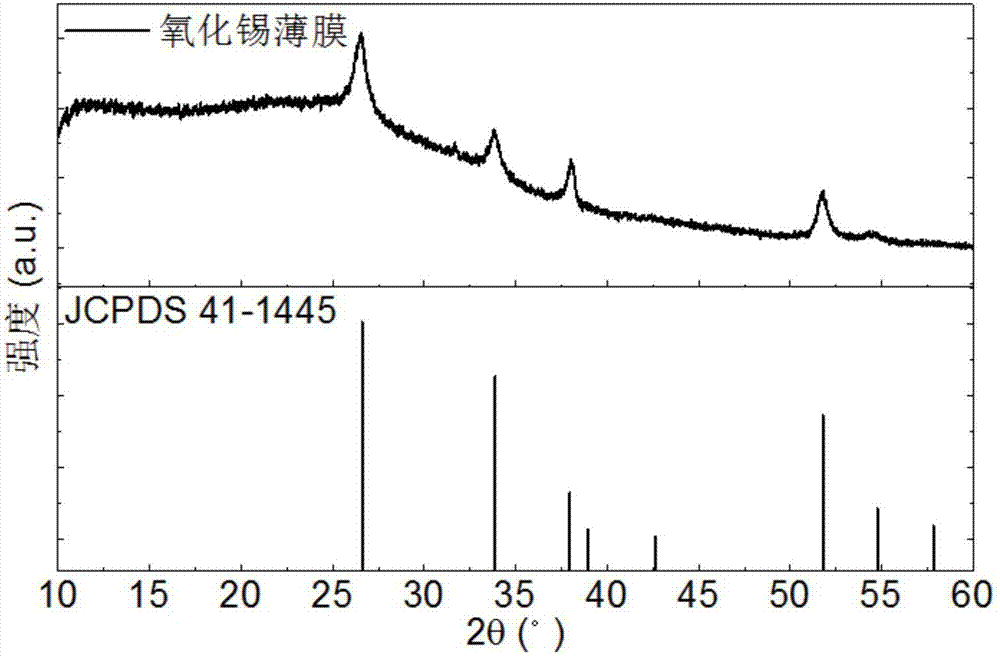

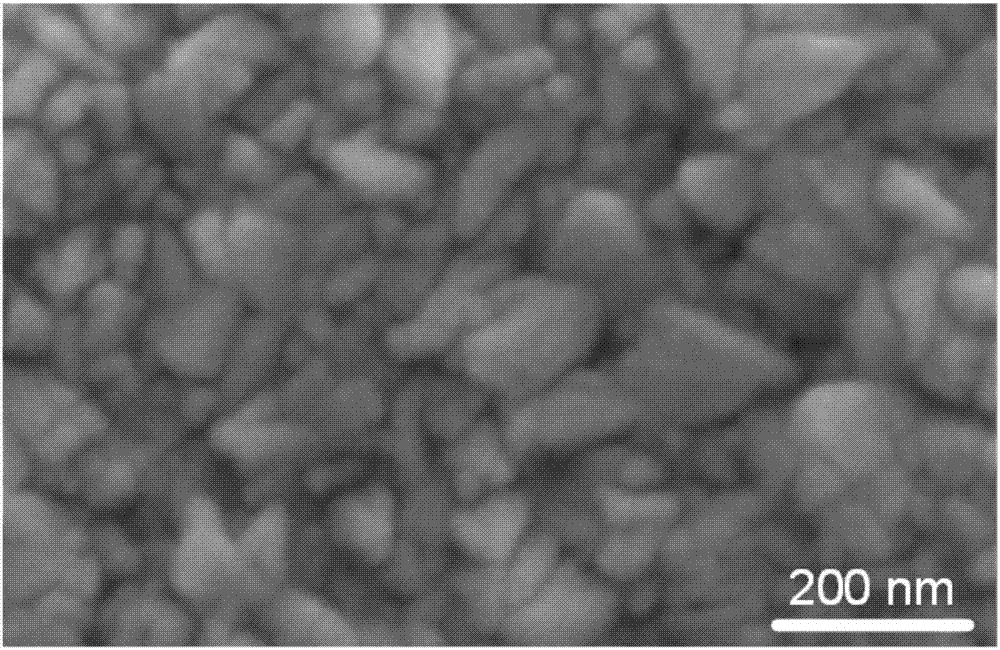

[0041]In the second step, a tin oxide film is prepared by spraying pyrolysis. Weigh 0.285g of stannous chloride, dissolve it in 20mL of deionized water, then add 5 drops of hydrochloric acid with a mass fraction of 36%, shake it to dissolve evenly, and put the cleaned 5cm×5cm FTO glass on the hot stage , adjust the temperature of the hot stage to 400°C and preheat for 10 minutes, put the precursor solution into the spray gun for spraying, after the spraying is completed, keep the temperature of the hot stage at 480°C, and perform annealing treatment for 30 minutes, then turn off the hot stage and let it Allow to cool naturally.

[0042] In the third step, the a...

Embodiment 2

[0046] The first step is to use the ultrasonic cleaning method to ultrasonically clean the FTO glass according to the following steps, each step is 30 minutes, and the heating temperature is 20-50°C: detergent + deionized water, acetone, isopropanol, ethanol, deionized water. After cleaning, blow dry with nitrogen.

[0047] In the second step, a tin oxide film is prepared by spraying pyrolysis. Weigh 0.285g of stannous chloride, dissolve it in 20mL of deionized water, then drop in 7 drops of hydrochloric acid with a mass fraction of 37%, shake it to dissolve evenly, put the cleaned FTO glass of 5cm×5cm on the hot stage , adjust the temperature of the hot stage to 430°C and preheat for 9 minutes, put the precursor solution into the spray gun and spray. Allow to cool naturally.

[0048] In the third step, the antimony selenide thin film is deposited by rapid thermal evaporation. Weigh 0.38g of antimony selenide powder and place it in the evaporation source. Set the evaporatio...

Embodiment 3

[0051] The first step is to use ultrasonic cleaning method to ultrasonically clean ITO or FTO glass according to the following steps, each step is 30 minutes, and the heating temperature is 20-50°C: detergent + deionized water, acetone, isopropanol, ethanol, deionized water . After cleaning, blow dry with nitrogen.

[0052] In the second step, a tin oxide film is prepared by spraying pyrolysis. Weigh 0.285g of stannous chloride, dissolve it in 20mL of deionized water, then add 10 drops of hydrochloric acid with a mass fraction of 38%, shake it to dissolve evenly, and put the cleaned 5cm×5cm FTO glass on the hot stage , adjust the temperature of the hot stage to 380°C and preheat for 15 minutes, put the precursor solution into the spray gun for spraying. Allow to cool naturally.

[0053] In the third step, the antimony selenide thin film is deposited by rapid thermal evaporation. Weigh 0.38g of antimony selenide powder and place it in the evaporation source. Set the evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com