Device and method for measuring saturation adsorption capacity of porous material

A technology of porous materials and measuring devices, which is applied in the direction of material absorption and weighing, can solve the problems of cumbersome operation and inaccurate test results, and achieve the effects of simple operation, avoiding contact between samples and air, and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

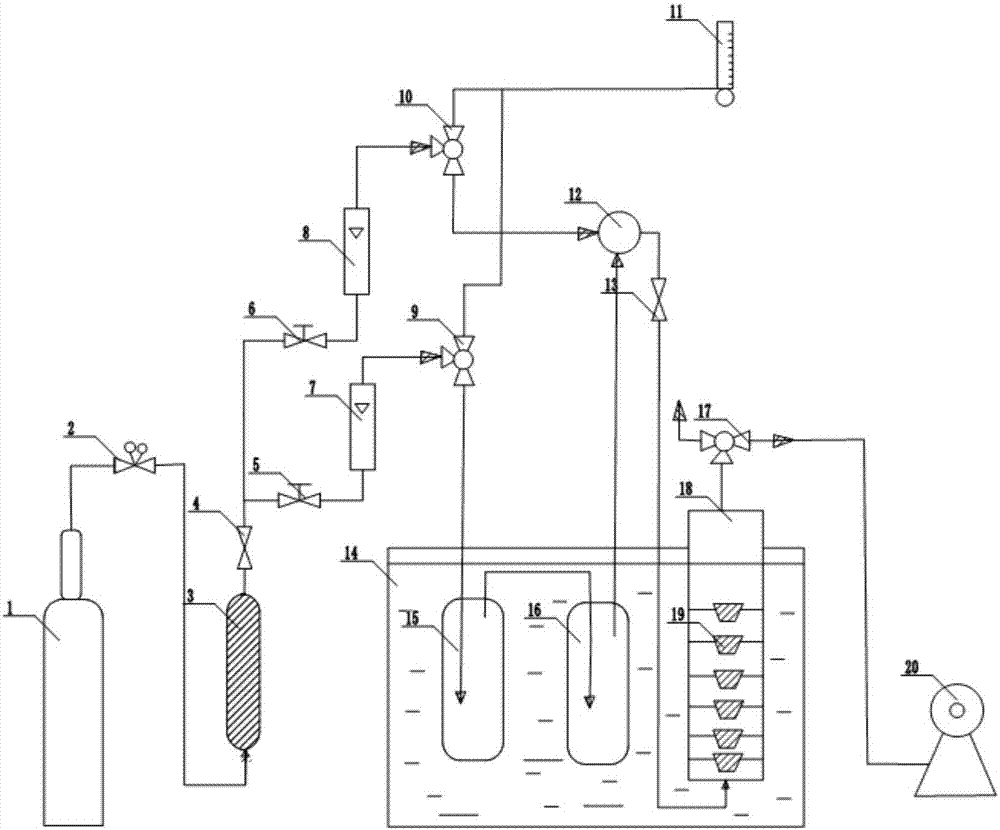

[0036] Utilize the measuring device I measurement analysis process of above-mentioned porous material saturated adsorption capacity as follows:

[0037] Open the valve of the gas extraction chamber 1, reduce the pressure of the precision decompression gauge 2 to below 0.5MPa, dry the gas through the drying column 3, open the first control valve 4, connect the three-way valve D9 to the soap bubble flow meter 11, and adjust the flow rate Open the valve V5 and calibrate the rotameter V7 through the soap bubble flowmeter 11. After the calibration is completed, close the flow regulating valve V5, connect the three-way valve E10 to the soap bubble flowmeter 11, open the flow regulating valve W6, and pass through the soap bubble flowmeter 11 to calibrate the rotameter W8, and close the flow regulating valve W6 after the calibration is completed.

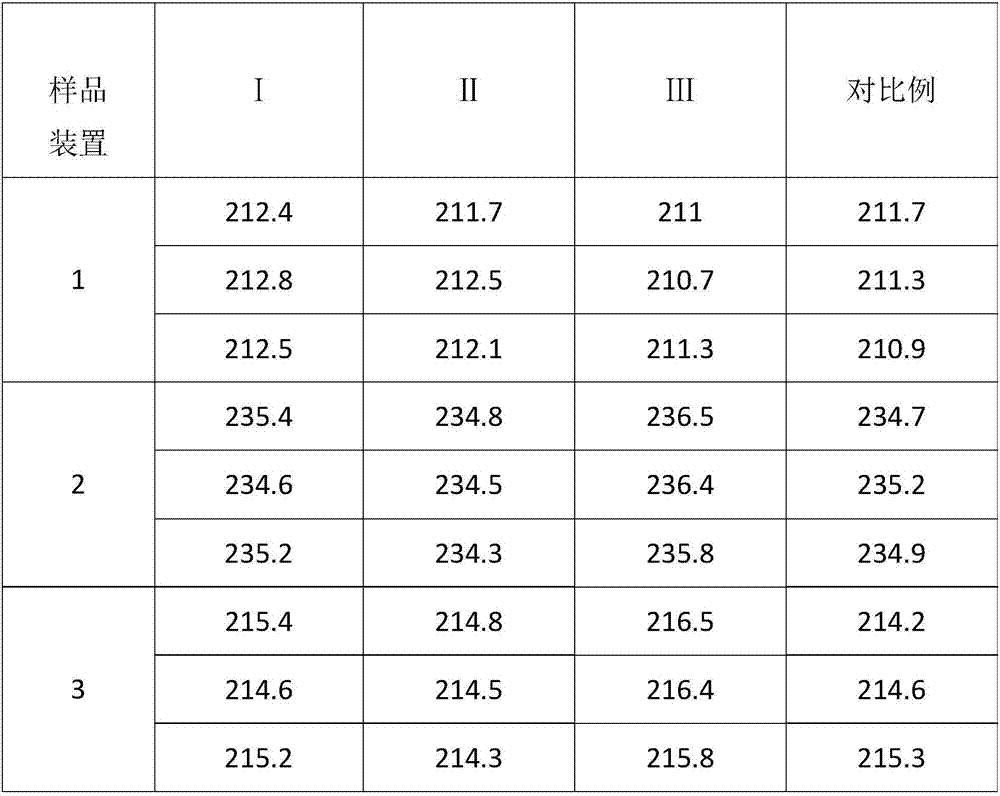

[0038] Take three weighing bottles, weigh them with caps and empty weights M0, record them, then quickly transfer sample 1 into the weighi...

Embodiment 2

[0041] The operation steps are the same as in Example 1, except that the porous material is replaced with Sample 2, and the results are shown in Table 1.

Embodiment 3

[0043] The operation steps are the same as in Example 1, except that the porous material is replaced with Sample 3, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com