Small film rolling machine used for spacecraft hot test electrical fitting technology

A thermal test, spacecraft technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of time-consuming operation and low efficiency, and achieve the effect of improving work efficiency and lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The small film rolling machine used for spacecraft thermal test electrical equipment process of the present invention will be further described below in conjunction with the accompanying drawings. This description is only exemplary and is not intended to limit the protection scope of the present invention.

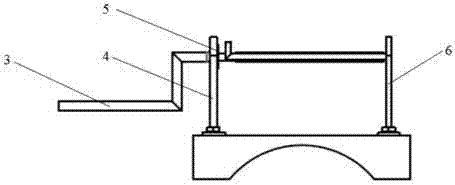

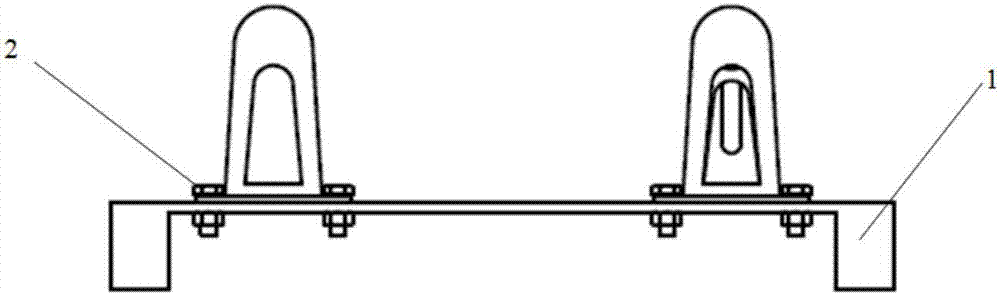

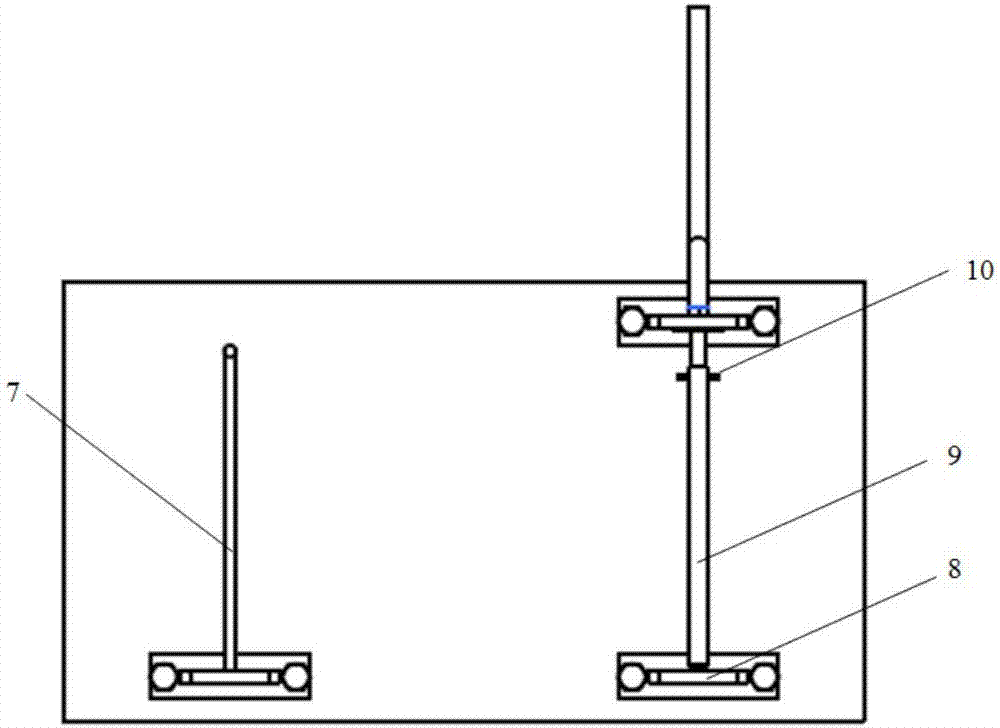

[0019] see figure 1 , the small-sized film rolling machine that is used for spacecraft thermal test electric assembly process of the present invention, comprises base 1, rotating shaft frame 4, auxiliary shaft frame 8, film rolling roller 9, rocking bar 3, pin 10, film fixing bracket 6 ; wherein, a rolling bearing 5 is fixed on the rotating shaft frame 4 of the base 1 through the M8 screw 2, and the two are interference fits to ensure that the bearing 5 and the rotating shaft frame 4 are tightly connected and no relative displacement occurs; After the rod 3 passes through the bearing 5, the variable-diameter section is used to ensure close contact with the inner rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com