Corrosion-resistant metal plate

A corrosion-resistant alloy and metal plate technology, which is applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve the problems that are difficult to meet the needs of oil and gas field development, corrosion resistance reliability, and economic indicators are difficult to balance, etc. problems, achieve excellent mechanical properties, good corrosion resistance, and prolong the life of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

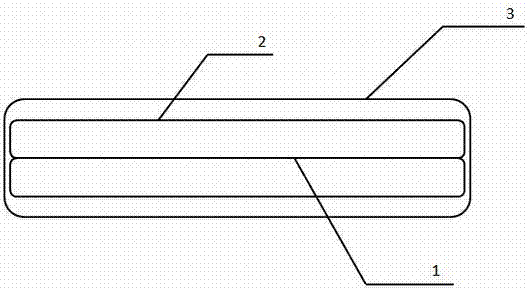

[0017] Such as figure 1 As shown, the present invention provides a kind of corrosion-resistant metal plate, and described metal plate is carbon steel plate body, corrosion-resistant alloy layer and anticorrosion coating sequentially from the inside of plate body outward, and between described carbon steel plate body and corrosion-resistant alloy layer form a confined space.

[0018] As a preference, the anti-corrosion coating is a graphene water-based coating layer.

[0019] Further, the carbon steel plate body and the corrosion-resistant alloy layer are combined through a hot rolling process.

[0020] The metal plate used in this embodiment is a mechanical composite plate, which is a new type of plate that combines two metal plates of different materials through mechanical manufacturing processes such as hydraulic expansion method, elastic body extrusion method or explosion method. It fully combines the high-strength properties of the substrate (carbon steel body) and the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com