Cavity sealing

An airfoil, metal material technology, applied in electron beam welding equipment, non-electric welding equipment, laser welding equipment, etc., can solve the problems of difficult quality control of opening fillers, insufficient chemical resistance and heat resistance of damping materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

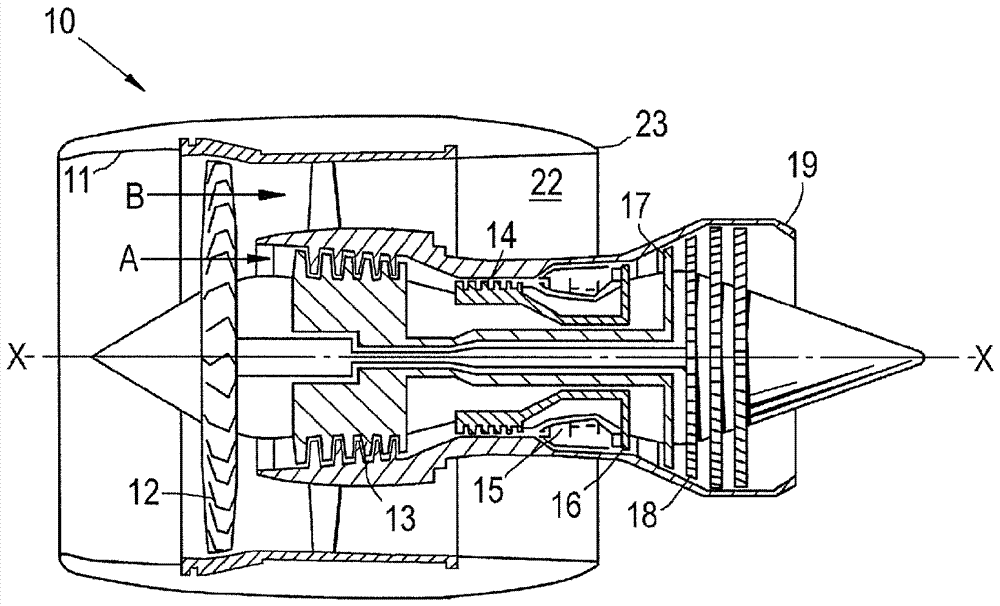

[0058] refer to figure 1 , a ducted fan gas turbine engine generally indicated by 10 has a principal and axis of rotation X-X. The engine 10 comprises, in axial sequence, an air intake 11, a propulsion fan 12, an intermediate pressure compressor 13, a high pressure compressor 14, a combustion equipment 15, a high pressure turbine 16, and an intermediate pressure turbine 17, a low pressure turbine 18 and a core engine discharge nozzle 19. The engine also has a bypass duct 22 and a bypass discharge nozzle 23 .

[0059] The gas turbine engine 10 operates in a conventional manner so that air entering the air intake 11 is accelerated by the fan 12 to generate two air flows: a first air flow A entering the intermediate pressure compressor 13 and passing through a bypass duct 22 to provide The second air flow B for propulsion thrust. The medium pressure compressor 13 compresses the air flow A introduced thereto before delivering this air to the high pressure compressor 14 where fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com