Weeding device used in vegetable planting greenhouse

A technology for greenhouses and vegetables, which is applied to the field of weeding devices for vegetable growing greenhouses, can solve the problems that drugs are easy to remain in the land, affect the growth of planted plants, and cannot remove weeds, and achieves an increase in the area of single weeding and a small overall structure. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

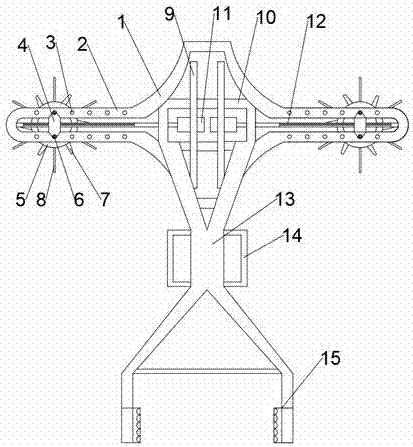

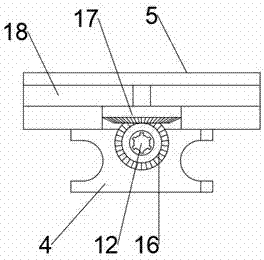

[0018] Such as figure 1 with figure 2 As shown, the present invention provides a weeding device for vegetable planting greenhouses, comprising a front frame 1, a U-shaped frame 2, an inner rectangular frame 10 and a supporting frame 13, and the U-shaped frame 2 is installed on both sides of the front frame 1 , the U-shaped frame 2 is equipped with a weeding mechanism through screws 6, the bottom of the U-shaped frame 2 is equidistantly provided with screw holes 3, the inner rectangular frame 10 is fixedly installed in the middle of the front frame 1, and the inner rectangular frame 10 is installed with a parallel wheel 9 through a bearing, and a motor 11 is arranged in the middle of the parallel wheel 9, and the rotating shaft of the motor 11 passes through the inner square frame 10 and is connected with a key shaft 12 on both sides, and the key shaft 12 passes through a U-shaped The front of the frame 2 is movable and fixed on the U-shaped frame 2, and the bottom of the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com