Rotors, permanent magnet embedded motors, compressors, and air conditioners

A technology of permanent magnets and rotors, which is applied to synchronous motors, compressors, and electric components with stationary armatures and rotating magnets. It can solve the problems of increased torque ripple and reduce torque ripple and reduce torque. Sustained effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

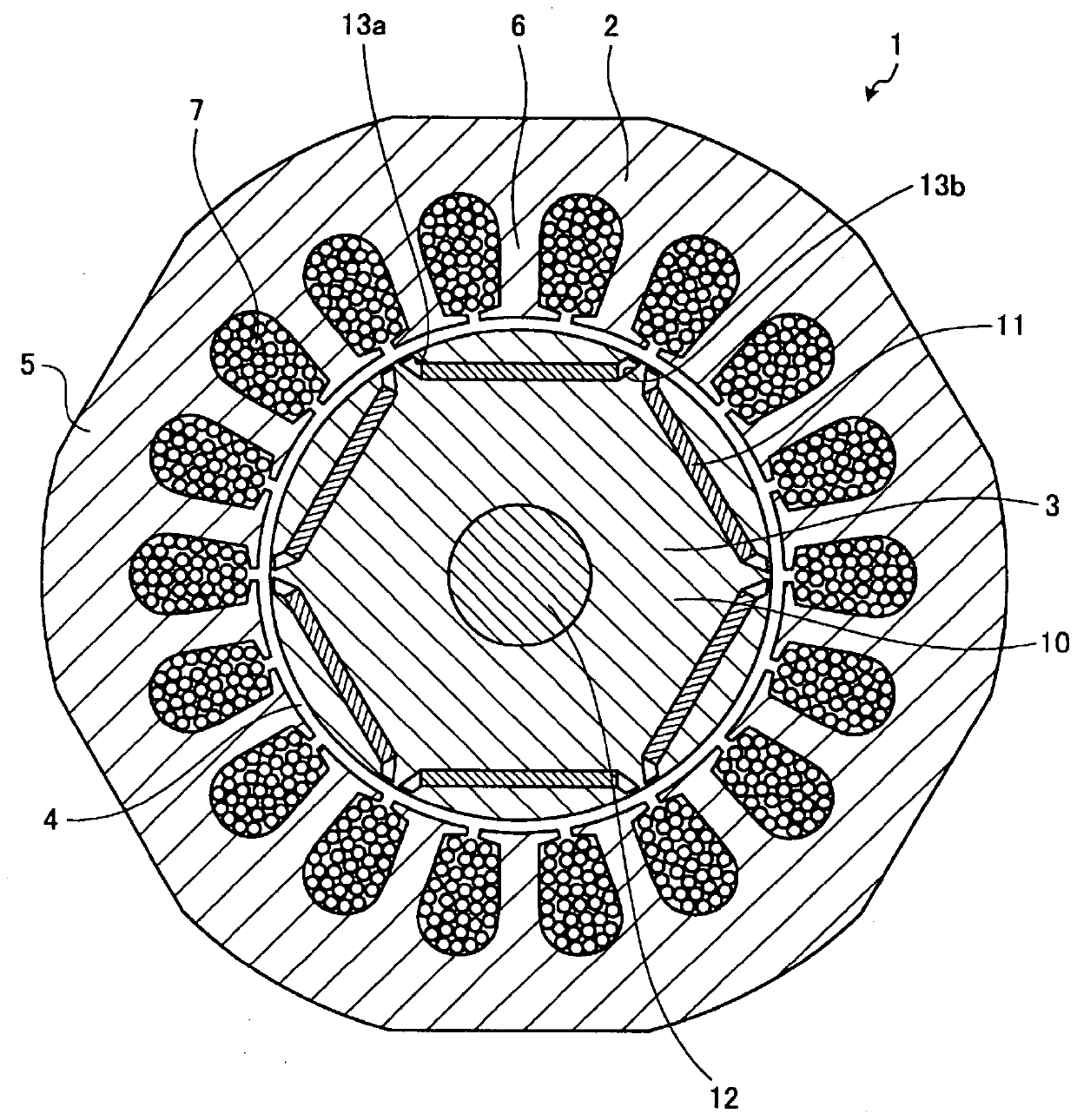

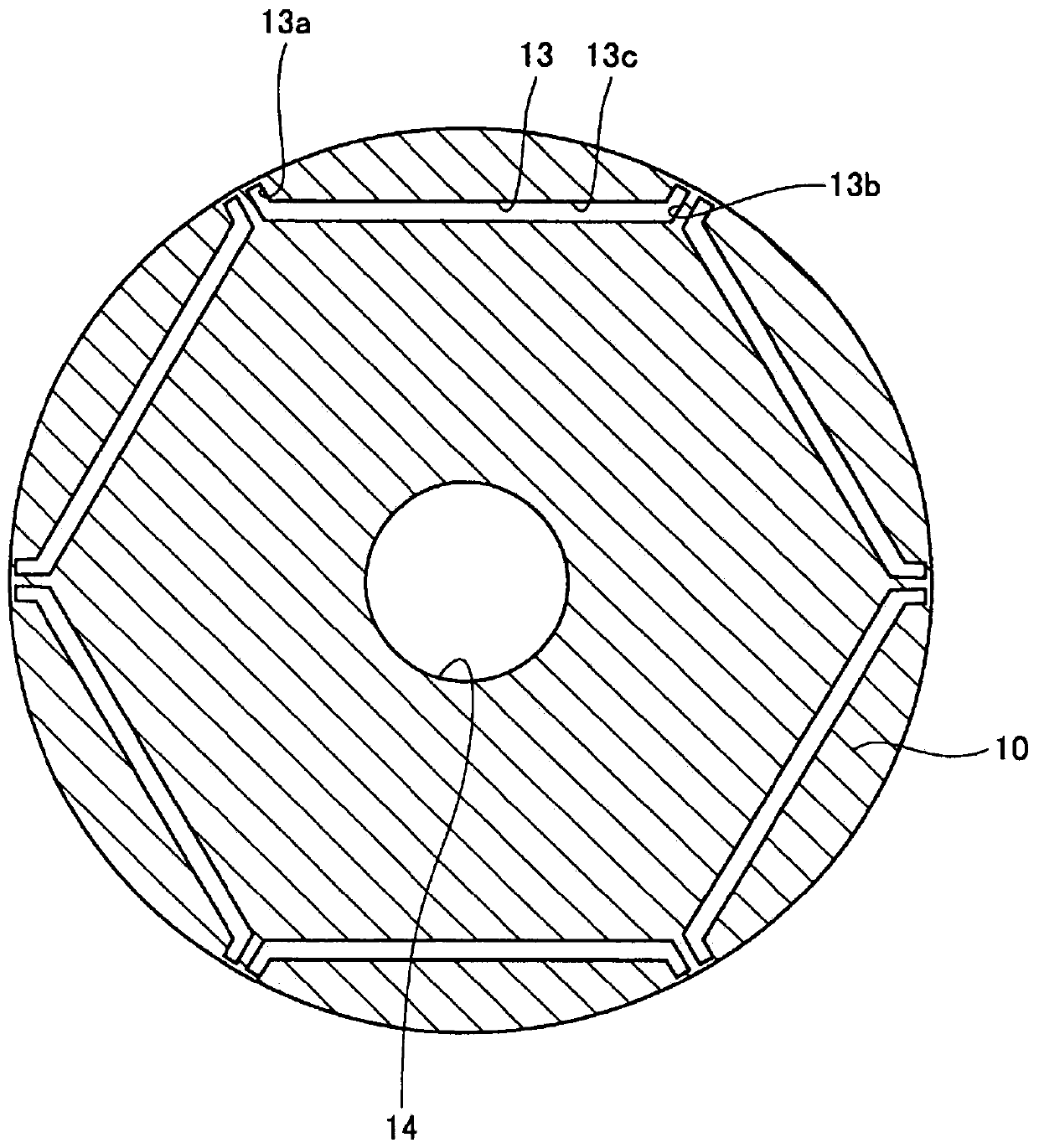

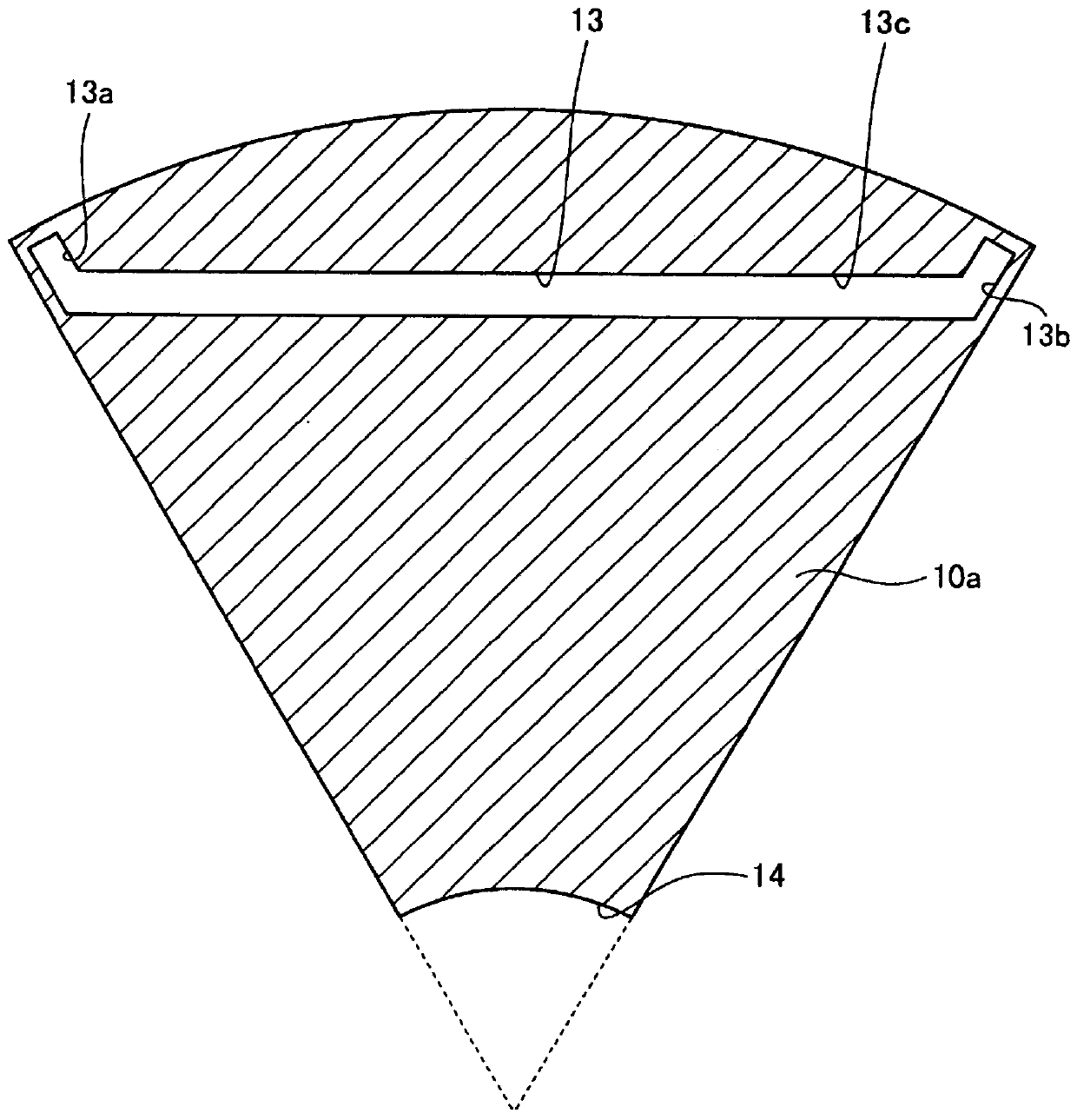

[0026] figure 1 is a cross-sectional view showing the structure of the permanent magnet embedded motor according to the present embodiment, figure 2 It is a sectional view of the rotor core of this embodiment. As described later, figure 1 as well as figure 2 It is a figure which shows the cross-sectional structure of the 1st core block among the 1st and 2nd core blocks which comprise a rotor core.

[0027] An embedded permanent magnet motor 1 includes an annular stator 2 and a rotor 3 disposed radially inside of the stator 2 with a gap 4 interposed therebetween.

[0028] The stator 2 includes an annular stator core 5 and a coil 7 wound around a plurality of teeth 6 formed on the inner peripheral surface of the stator core 5 . The teeth 6 are arranged at equal intervals in the circumferential direction of the stator 2 and extend in the radial direction of the stator core 5 .

[0029] The winding 7 is distributedly wound. In distributed winding, the winding 7 is wound ac...

Embodiment approach 2

[0062] Figure 11 It is a figure which shows the structure of the air conditioner which concerns on this embodiment. The air conditioner 100 according to this embodiment includes an indoor unit 101 and an outdoor unit 102 connected to the indoor unit 101 . The outdoor unit 102 includes the compressor 103 according to this embodiment. The embedded permanent magnet motor 1 of the first embodiment is used for the compressor 103 . In addition, the permanent magnet embedded motor 1 includes Modifications 1 and 2 described in the first embodiment.

[0063] Energy-saving performance is required for the air conditioner 100, and high efficiency is required. Furthermore, in order to suppress the vibration and noise which generate|occur|produce from the air conditioner 100 below a reference value, it is necessary to reduce the vibration and noise which generate|occur|produce from the compressor 103. The embedded permanent magnet motor 1 according to Embodiment 1 can suppress torque r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com