A component handling assembly

A technology for parts and assemblies, applied in the field of parts processing assemblies, which can solve problems such as part displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

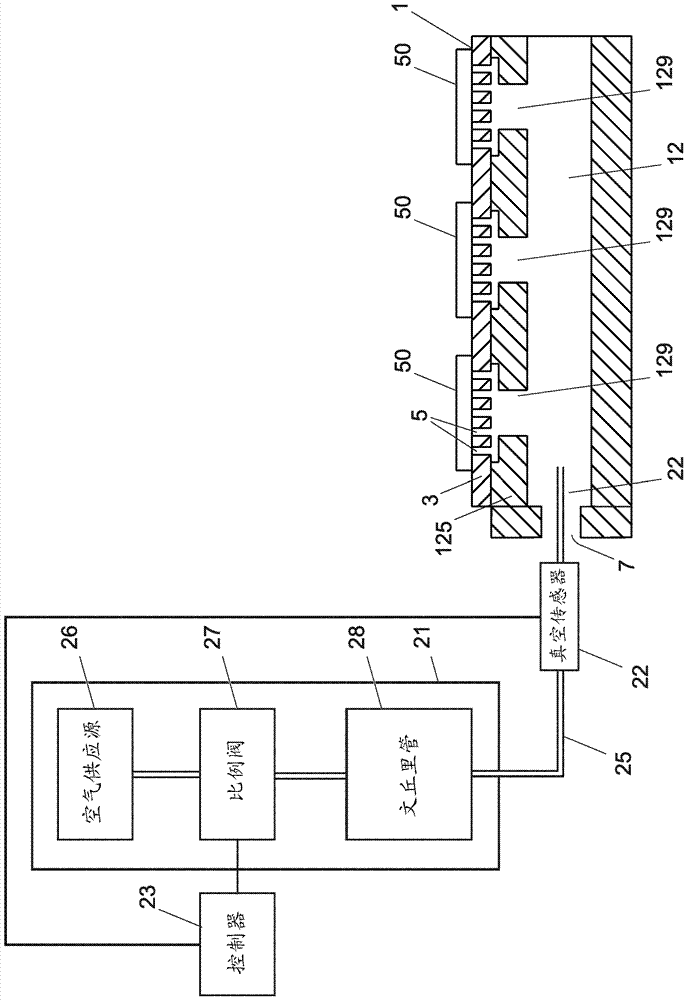

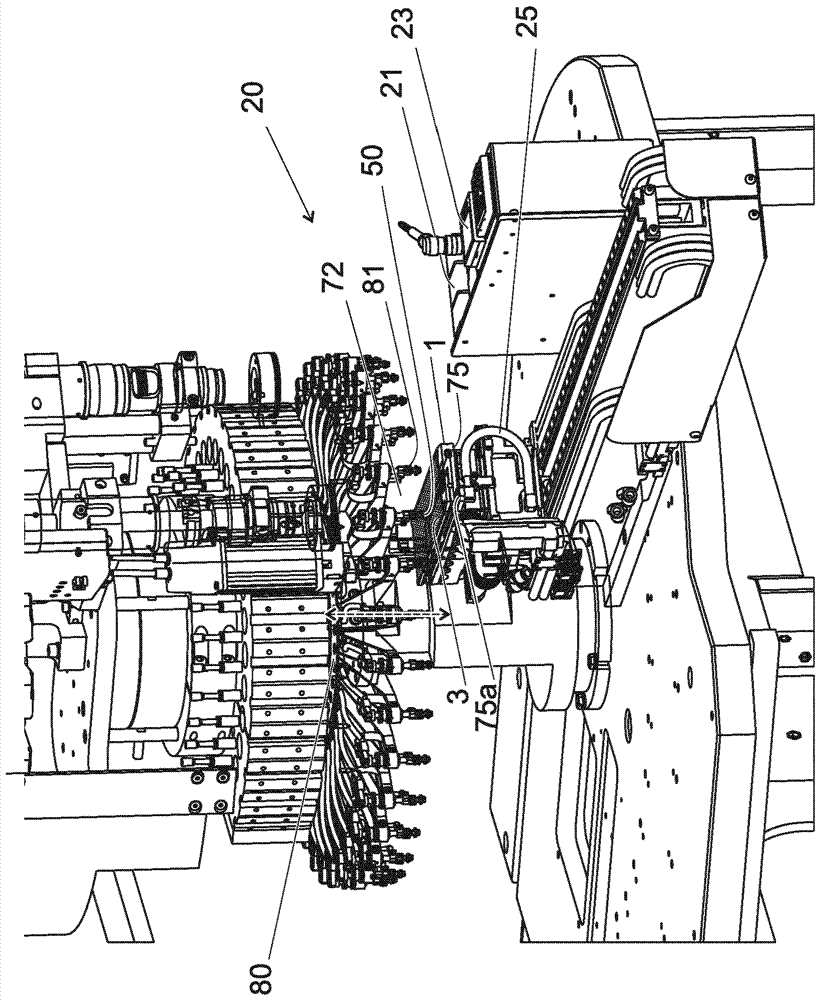

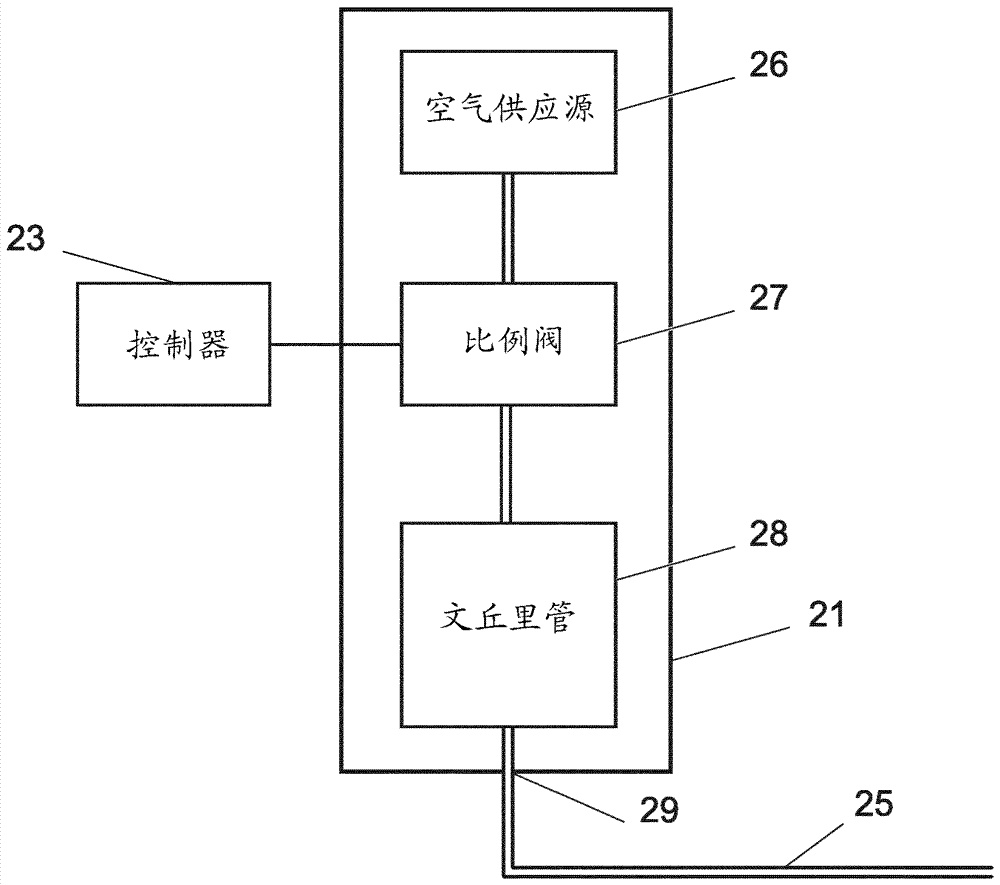

[0077] figure 1 A simplified longitudinal cross-sectional view of a portion of an exemplary carrier 1 that may be used in a parts handling assembly according to an embodiment of the invention is provided. In this example, the carrier 1 takes the form of a boat hull 1 . The carrier 1 comprises a surface 3 on which a plurality of components 50 have been loaded. The surface 3 has defined therein a plurality of holes 5 through which a vacuum can pass to hold the component 50 on the surface 3 .

[0078] exist figure 2 In the exemplary embodiment shown in , surface 3 is defined by metal layer 123 . Preferably, the metal layer 123 has a thickness "T" between 0.3 mm-2 mm; and the metal layer 123 preferably comprises a metal sheet. For example, metal layer 23 may comprise any suitable material, such as aluminum alloy, steel, copper alloy, glass, silicon. A hole 5 is defined in the metal layer 123 . Preferably, the holes 5 are formed in the metal layer 123 by drilling or etching....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com