Composition for forming coating film and method for forming coating film using same

一种组合物、覆膜的技术,应用在涂层等方向,能够解决气体阻隔性能不充分等问题,达到优异气体阻隔性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below.

[0029] Composition for film formation

[0030] The film-forming composition of the present invention contains a silicon compound, a polysilazane, and an organic solvent as essential components, and may contain other additives as necessary. These respective components are described as follows.

[0031] silicon compound

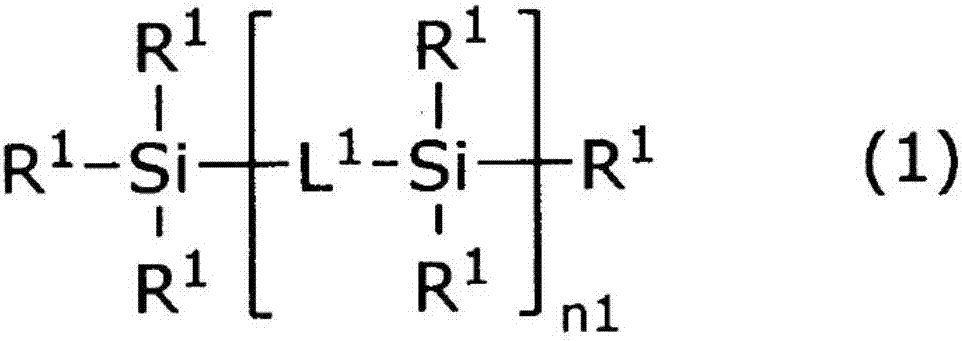

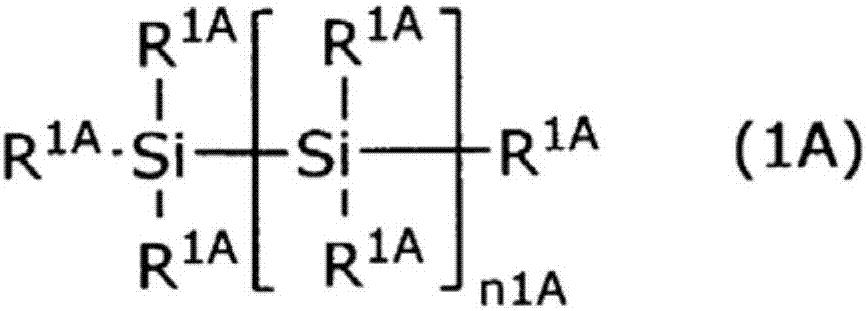

[0032] In the present invention, a silicon compound having a specific structure is used as the silicon compound. When the composition layer formed from the film-forming composition of the present invention is exposed to light, the silicon compound reacts with polysilazane described later to form a cured film. This silicon compound is a compound represented by the following general formula (1).

[0033]

[0034] In the formula, R 1 Each is independently selected from hydrogen, halogen atom, hydrocarbon group, hydroxyl group, hydrocarbon hydroxyl group, acyl group, acyloxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com