Near-distance 3D water-saving cleaner for strip-shaped base material

A technology for cleaning machines and substrates, applied in the field of cleaning machines, can solve problems such as unfavorable water resources utilization, large water consumption, and large pollution, and achieve the effects of rapid replacement, scientific structure, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

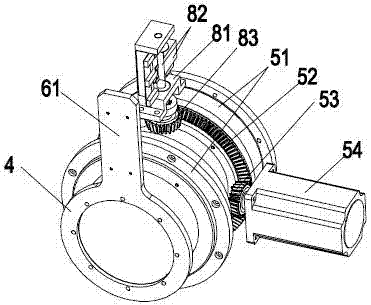

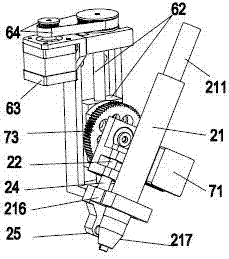

[0031] see Figure 1~Figure 10 , it can be seen from the figure that the short-distance 3D water-saving cleaning machine for strip-shaped substrates includes a cleaning platform 01, a substrate 1, a cleaning assembly 2, a cleaning head 3, a hollow rotating shaft 4, a head protection mechanism 8, and a strip-shaped substrate. The material 04 is automatically centered with the substrate clamping assembly 9; the substrate 1 is set on the cleaning platform 01; the cleaning platform 01 is provided with a waste water recovery funnel 06, and the bottom of the cleaning platform 01 is provided with a waste water recovery tray 02 for collecting cleaning wastewater The cleaning assembly 2 is arranged on the cleaning head, and the self-inflating compressed air tank 03 and the water tank 07 are arranged in the cleaning platform 01; the cleaning assembly 2 is arranged on the cleaning head 3, and the cleaning head 3 can be rotated with the 4 is rotatably arranged at the end of the hollow rot...

Embodiment 2

[0040] On the basis of Embodiment 1, this embodiment serves as an extension of the function of the 3D water-saving cleaning machine for strip-shaped substrates. Figure 11As shown, the 3D water-saving cleaning machine also includes a cleaning platform 01, the substrate 1 is slidably arranged on the cleaning platform 01, the bottom of the cleaning platform 01 is provided with a waste water recovery tray 02 for collecting cleaning wastewater, and the cleaning platform 01 is provided with There is a pedestal movement mechanism 05 that drives the substrate 1 to move on the cleaning platform 01; the pedestal movement mechanism 05 is an axial movement mechanism that moves linearly along the axial direction of the bar-shaped substrate 04 or an X-Y movement mechanism that moves vertically and horizontally; wherein: the axis The axial movement mechanism includes an axial movement motor arranged on the base plate 1, the axial movement motor is provided with an axial movement gear, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com