Anti-disassembling threaded component and mobile terminal having anti-disassembling threaded component

A threaded component and anti-disassembly technology, which is applied in the direction of threaded fasteners, screws, bolts, etc., can solve the problems of being unable to judge whether the product has been altered or damaged by others, disgusting disassembly of mobile terminals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] like Figure 6-9 As shown, the present invention provides an anti-disassembly thread assembly, including a hollow screw 330, a self-locking mechanism 340, and a screw removal tool 400 for dismounting the hollow screw 330, and the hollow screw 330 is installed between the upper and lower housings In the threaded hole, the self-locking mechanism 340 is arranged at the end of the threaded rod of the hollow screw 330, the hollow screw 330 is provided with a through hole 333, and the push rod 403 of the screw removing tool 400 is inserted into the through hole 333 and acts on the self-locking mechanism 340.

[0068] Among them, the self-locking mechanism 340 is used to limit the rotation of the hollow screw 330. After the hollow screw 330 is tightened, the self-locking mechanism 340 can prevent the hollow screw 330 from being completely unscrewed by ordinary dismounting tools, thereby preventing the screw from being disgusted by others. Disassembly to make changes to the en...

Embodiment 2

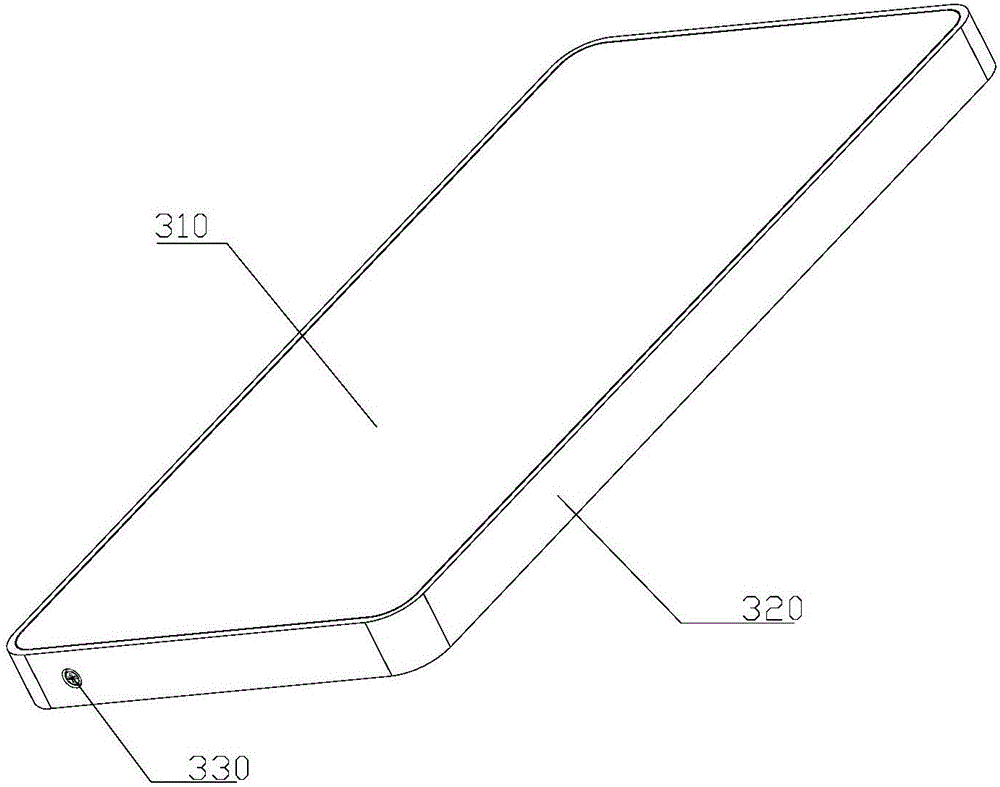

[0090] Based on the same inventive concept, on the other hand, such as image 3 , 4 As shown, the present invention also provides a mobile terminal, including a tamper-resistant screw assembly, the self-locking mechanism 340 is installed inside the mobile terminal; the self-locking mechanism 340 is fixedly arranged on the lower shell of the mobile terminal body 320, corresponding to the end of the hollow screw 330.

[0091] like Figure 4 , 5 As shown, the mobile terminal includes an upper case (A case) 310 and a lower case (B case) 320, and the upper case 310 and the lower case 320 are fixed by a buckle structure and the hollow screw 330 Composing the accommodating cavity of the mobile terminal, an upper screw hole 311 and a lower screw hole 321 are respectively provided corresponding to the hollow screw 330, and the hollow screw 330 is arranged in the upper screw hole 311 and the lower screw hole 321 .

[0092] Specifically, such as Figure 6-9 As shown, the anti-disas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com