A Method for Improving the Working Reliability and Safety of High-Voltage Brushless DC Motor

A DC motor, reliability technology, applied in the direction of AC motor control, single motor speed/torque control, electrical components, etc., can solve the problems of increasing duty cycle, burning, etc., to reduce the risk of overcurrent and improve reliability , the effect of strong speed recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

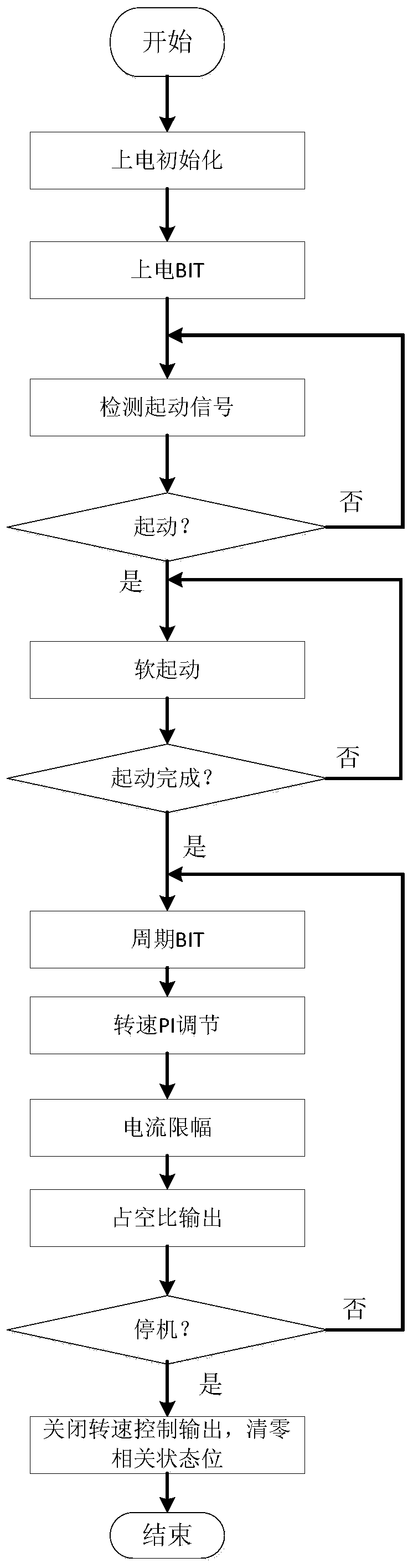

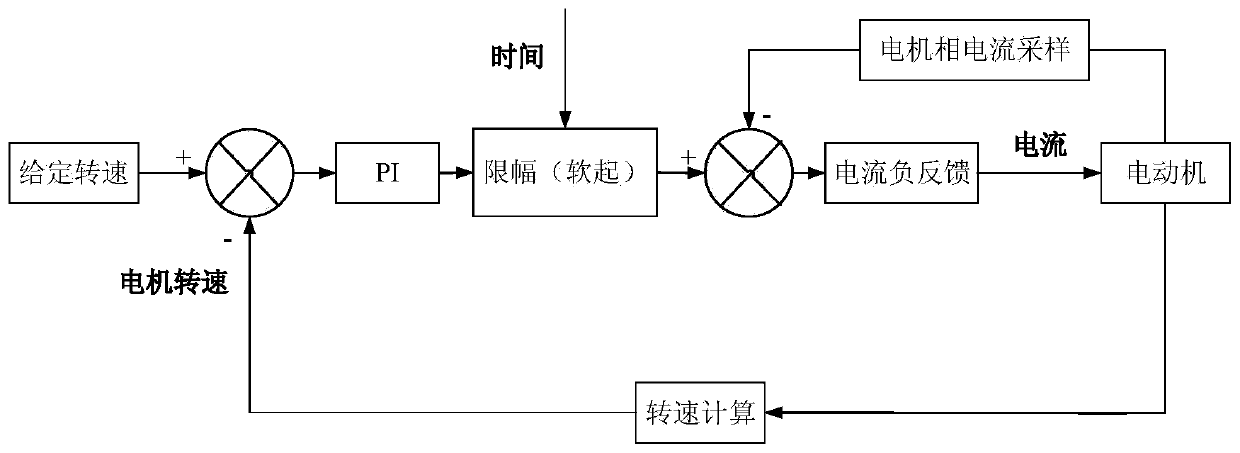

[0028] The method for improving the working reliability and safety of the high-voltage brushless DC motor proposed by the present invention adds an intermediate soft start module to the working logic of the motor controller, so that the motor can gradually increase the Duty cycle output, soft start to rated speed, which can avoid the problem of excessive driving current of the motor controller for a long time, or even burning out when sudden load, overload, or stall.

[0029] Specifically include the following steps:

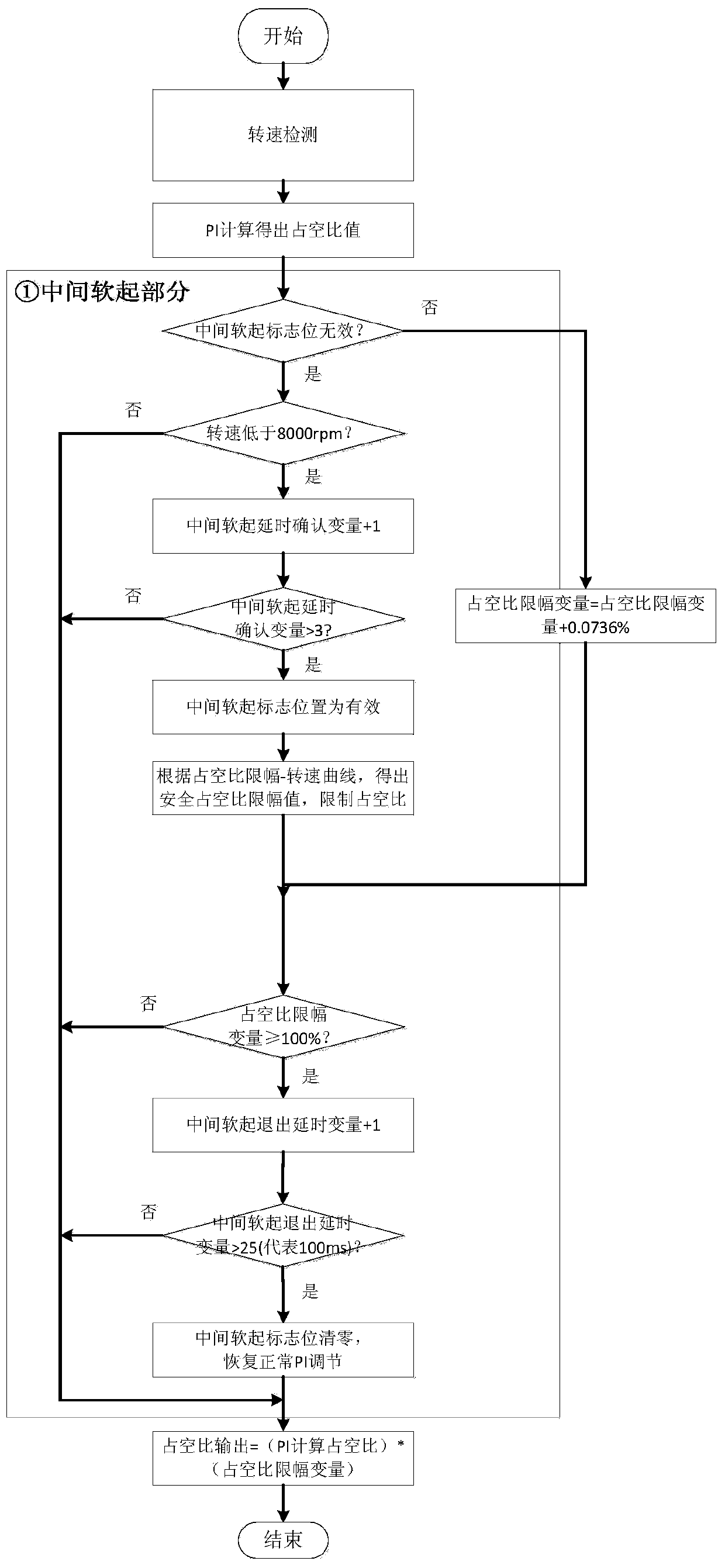

[0030] Step 1: Detect the motor speed and the bus current, and calculate the required PWM wave duty cycle according to the current speed using PI control.

[0031] Step 2: Determine whether the middle soft start flag is invalid, if invalid, go ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com