Preparation method of mimetic touch film and mimic blackboard applying mimetic touch film

A technology of touch film and touch sensing, which is applied in the input/output process of data processing, instruments, electrical digital data processing, etc. It can solve the problems of color difference, imitation is not realistic enough, and the blackness of display area is not deep enough, etc., to increase Display accuracy, deep screen blackness, and vivid colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare a 43-inch mimic touch film 10, and its preparation method is as follows:

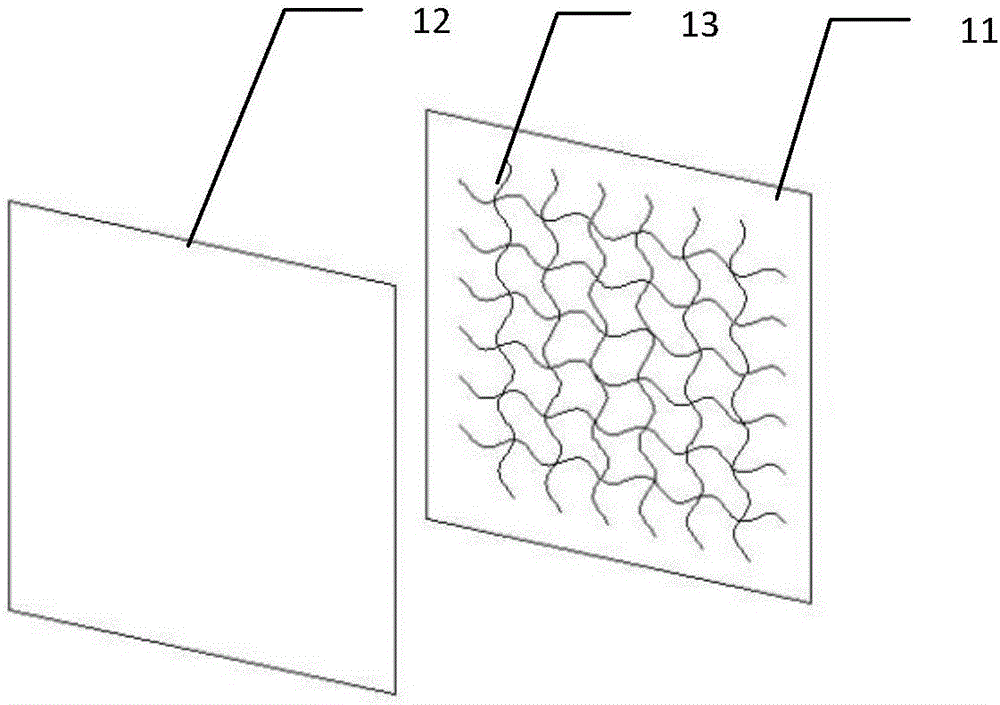

[0027] (1) First cut the polarizer 12 with adhesive on one side, and arrange the wires 13 on it by 3D printing for patterning;

[0028] (2) laminating the transparent optical film 11 with double-sided adhesive that has been cut according to the size and the patterned polarizer 12 in step 1) by machine dry bonding to obtain the mimic touch sensing layer 1;

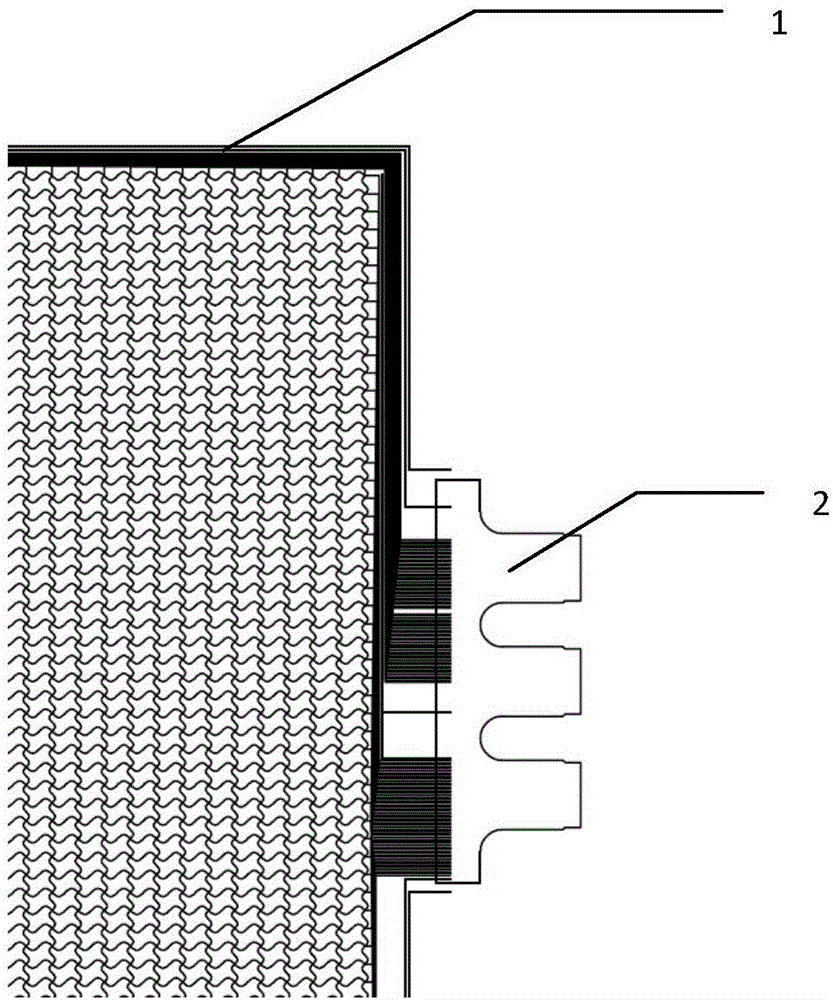

[0029] (3) Aligning and fitting the flexible circuit connector 2 linking the sensing area and the controller at the flicking part of the mimic touch sensing layer 1;

[0030] (4) The tail-flicking part is connected with the flexible circuit connector 2 linking the sensing area and the controller by means of laser welding or hot pressing to form a pseudo-touch film 10 .

Embodiment 2

[0032] Prepare a 55-inch mimic touch film 10, the preparation method of which is as follows:

[0033] 1) First cut out the transparent optical film 11 with adhesive on one side, and arrange the wires 13 on it by 3D printing for patterning;

[0034] 2) laminating the polarizer 12 cut to size with the patterned transparent optical film in step 1) by wet pasting 11 to obtain the mimic touch sensing layer 1;

[0035] 3) Aligning and fitting the flexible circuit connector 2 linking the sensing area and the controller at the flicking part of the mimic touch sensing layer 1;

[0036] 4) The flicking part is connected with the flexible circuit connector 2 linking the sensing area and the controller by means of laser welding or hot pressing to form a mimic touch film 10 .

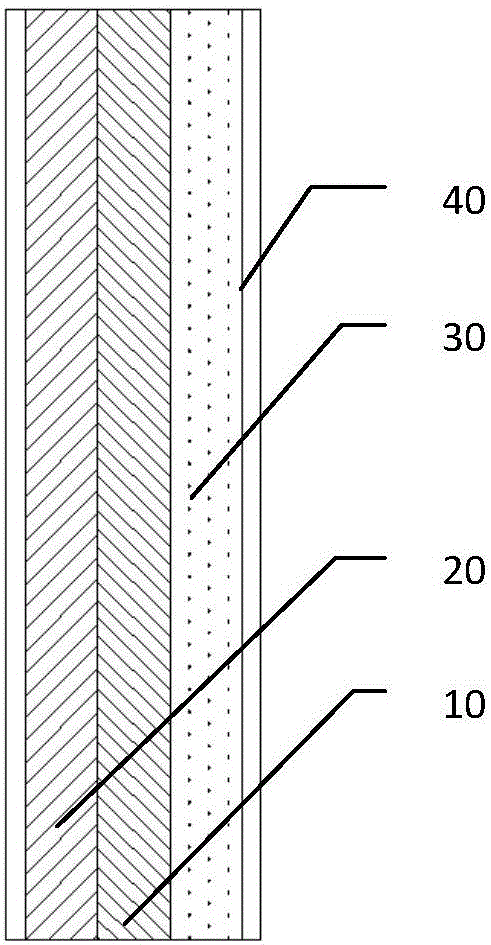

[0037] Such as image 3 As shown, the present invention also discloses a mimetic blackboard using the touch film, which consists of a transparent body 20 on the surface, a mimetic touch film 10 attached to the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com