Composite high-performance rubber hose for intercooler and its production and installation method and application

An intercooler, high-performance technology, applied in the intercooler composite high-performance rubber hose and the production, installation and application fields, can solve the problem of waste of automobile manufacturing costs, achieve high durability, good oil resistance and weather resistance, medium good electrical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

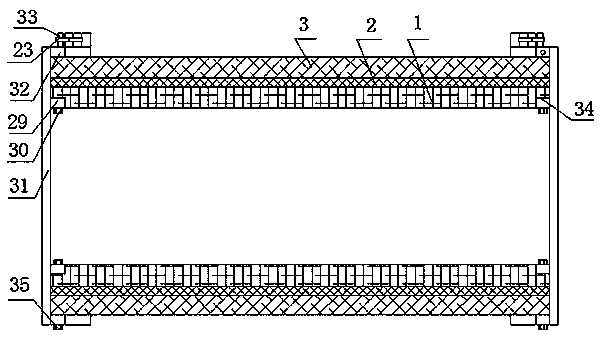

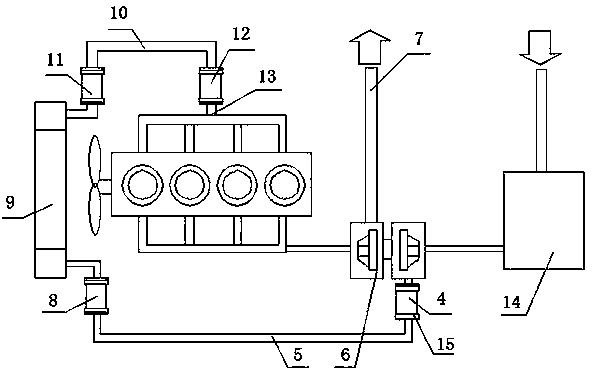

[0035] A production and installation method for intercooler composite high-performance rubber hose. The first step is to extrude the inner layer of acrylic rubber ACM material from a transverse extruder to form a rubber hose blank, and the second step is to pass the rubber hose blank through a knitting machine. The outer surface of the tube blank is knitted with aramid yarn, the third step is to set the temperature of each stage of the extruder, and the fourth step is to hang the outer layer of acrylic rubber ACM material on the knitted tube blank through another horizontal extruder , the fifth step is to cover the rubber hose tube blank on the rubber hose core and enter the vulcanization tank for vulcanization to make the supercharger intercooler rubber hose. The sixth step is inspection, packaging and storage.

Embodiment 2

[0037] The manufacturing and installation method of intercooler composite high-performance rubber hose described in Example 1, the temperature of each stage of the extruder in the third step is 80°C in the first stage, 70°C in the second stage, and 60°C in the third stage, The fourth stage is 50°C, the fifth stage is 70°C, the sixth stage is 60°C, and the seventh stage is 50°C.

Embodiment 3

[0039] The production and installation method of the intercooler composite high-performance rubber hose described in Example 1, the specification of the supercharger intercooler rubber hose is: the inner diameter of the rubber hose is more than φ45 mm, and the wall thickness of the rubber hose is 5-10 mm, the preferred solution 8 mm, the rubber hose is a special-shaped tube, and the shape is designed and manufactured according to actual needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com