A washing machine solenoid valve energy-saving circuit

An energy-saving circuit, solenoid valve technology, applied in valve details, valve devices, mechanical equipment, etc., can solve the problems of small diameter coil solenoid valves easily damaged, high cost of double coils, and difficult winding, etc., to reduce The effect of working current, prolonging service life and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

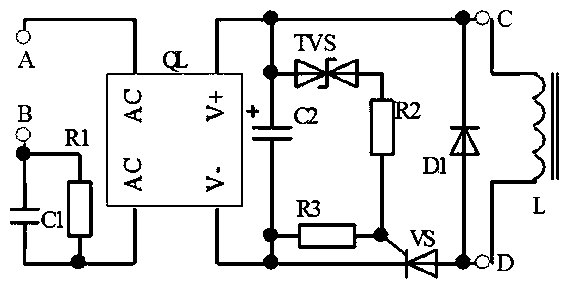

[0016] Such as figure 1 Shown: a washing machine solenoid valve energy-saving circuit, composed of thyristor trigger circuit, thyristor VS, solenoid valve coil L and diode D1. The thyristor trigger circuit is constructed by current limiting capacitor C1, rectifier bridge QL, energy storage capacitor C2, TVS tube (transient voltage suppressor diode) and resistors R1, R2, and R3. The specific line relationship connection is as follows:

[0017] One end of the current-limiting capacitor C1 is used as a terminal of the solenoid valve to connect to the terminal B of the solenoid valve control circuit of the washing machine, the other end of the current-limiting capacitor C1 is connected to an AC input terminal AC of the rectifier bridge QL, and the other AC input terminal of the rectifier bridge is connected to AC Terminal A of the solen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com