Gear shifting mechanism

A technology of speed change mechanism and transmission mechanism, applied in mechanical equipment, chain elements, transmission chain, etc., can solve the problems of high processing precision, complex structure, few gears, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

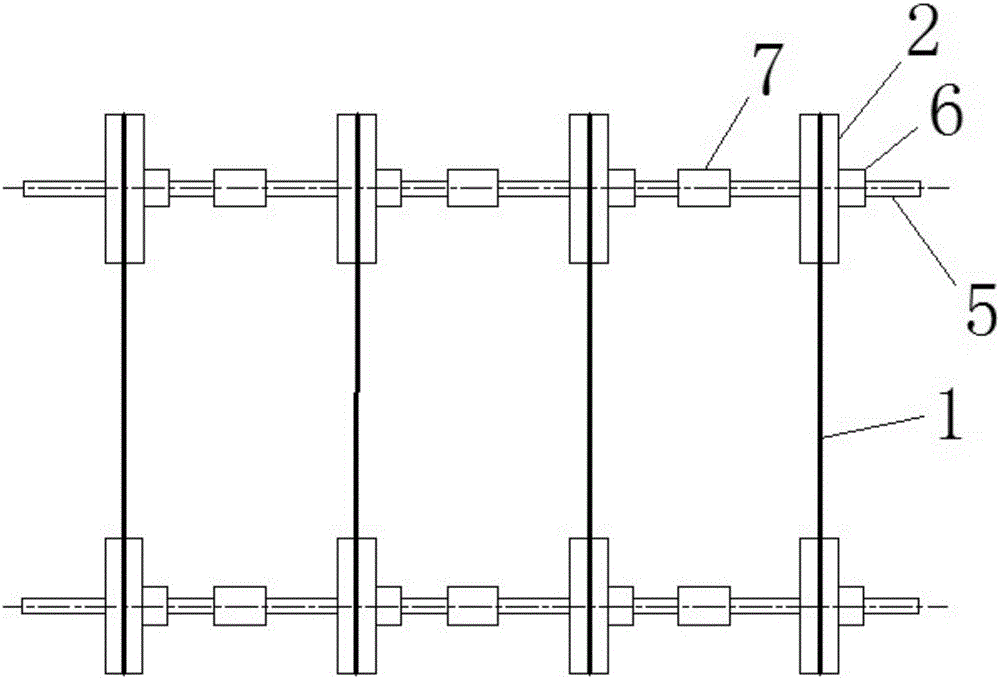

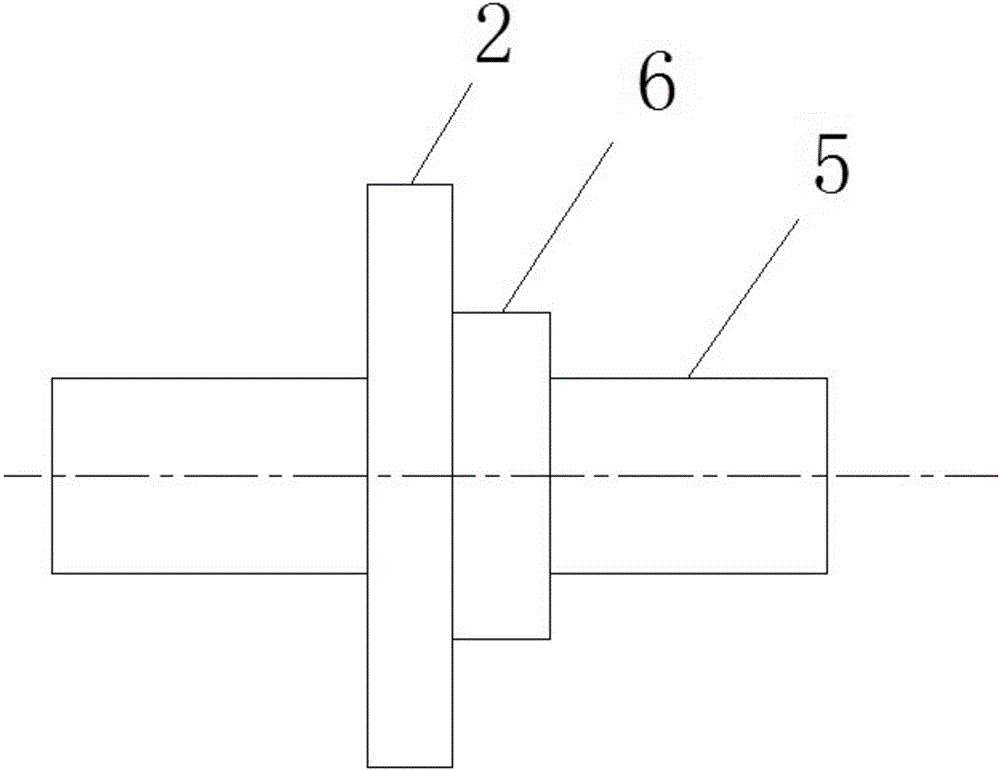

[0055] Such as figure 1 As shown, a speed change mechanism includes two parallel and opposite first shaft systems, and the first shaft systems include several such as image 3 The transmission mechanism shown, the transmission mechanism includes such as Figure 4 Shown shaft 5, the sprocket 2 is set on the shaft 5, and the shaft 5 and the sprocket 2 are provided with Figure 5 The first connecting sleeve 6 shown, the shaft 5 and the first connecting sleeve 6, the first connecting sleeve 6 and the sprocket 2 are clearance fit, the shaft 5 and the first connecting sleeve 6, the first connecting sleeve 6 and the sprocket 2 They are all keyed connections; the two adjacent transmission mechanisms on the first shafting system are connected through such as Figure 6 The second connecting sleeve 7 shown is connected, the second connecting sleeve 7 and the shaft 5 are in clearance fit, and the second connecting sleeve 7 and the shaft 5 are in a key connection; the sprockets 2 on the ...

Embodiment 2

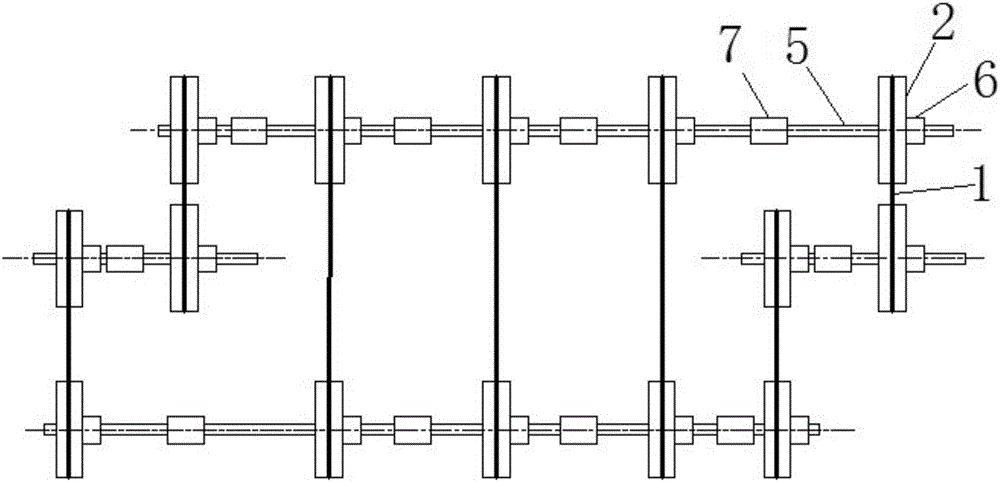

[0082] It differs from Embodiment 1 in that: as figure 2 As shown, the speed change mechanism also includes a second shaft system and a third shaft system, the second shaft system includes two transmission mechanisms, the two transmission mechanisms are connected through the second connecting sleeve 7, and the third shaft The system includes two transmission mechanisms, the two transmission mechanisms are connected through the second connecting sleeve 7, the second shaft system is respectively connected to one end of the two first shaft systems through two chains 1, and the third shaft system is connected through two chains 1 Connect the other ends of the two first shaft systems respectively.

[0083] In this embodiment, the second axis and the third shaft system serve as torque input and torque output respectively, and play a role in flexibly arranging the input and output shafts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com