Electromagnetic urea pump for diesel engine exhaust treatment

A diesel engine and exhaust gas treatment technology, applied in exhaust gas treatment, engine components, machines/engines, etc., can solve problems affecting the development of diesel automobile industry, etc., and achieve the effects of simple structure, small overall volume and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

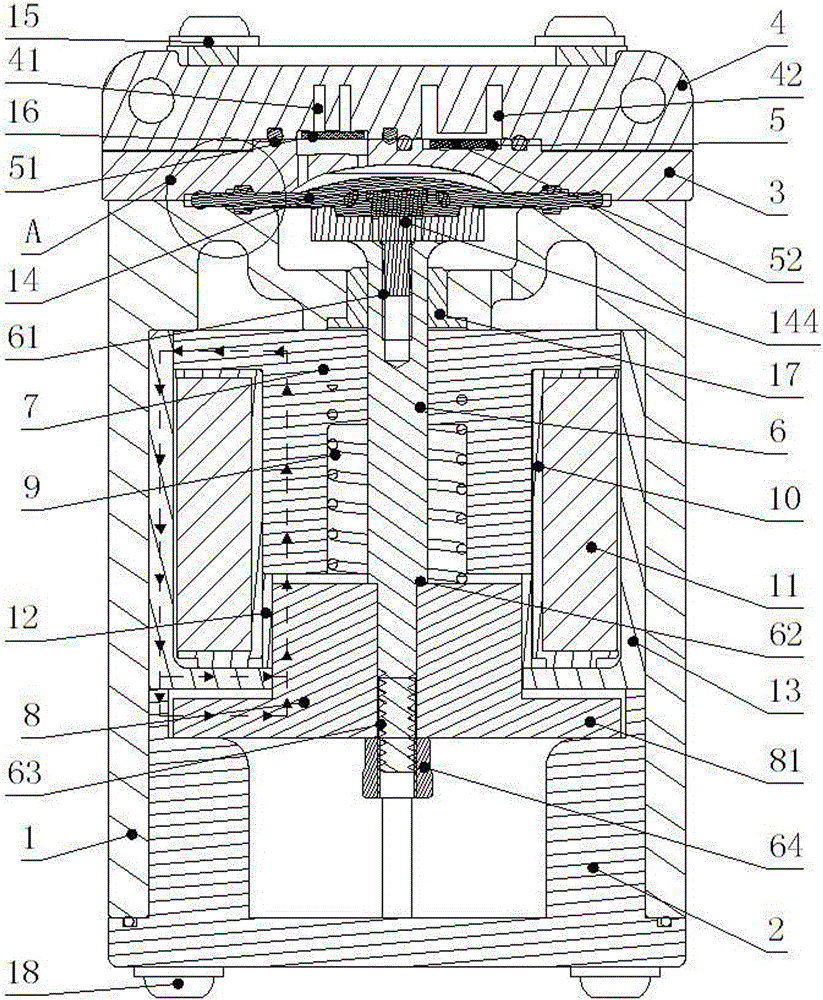

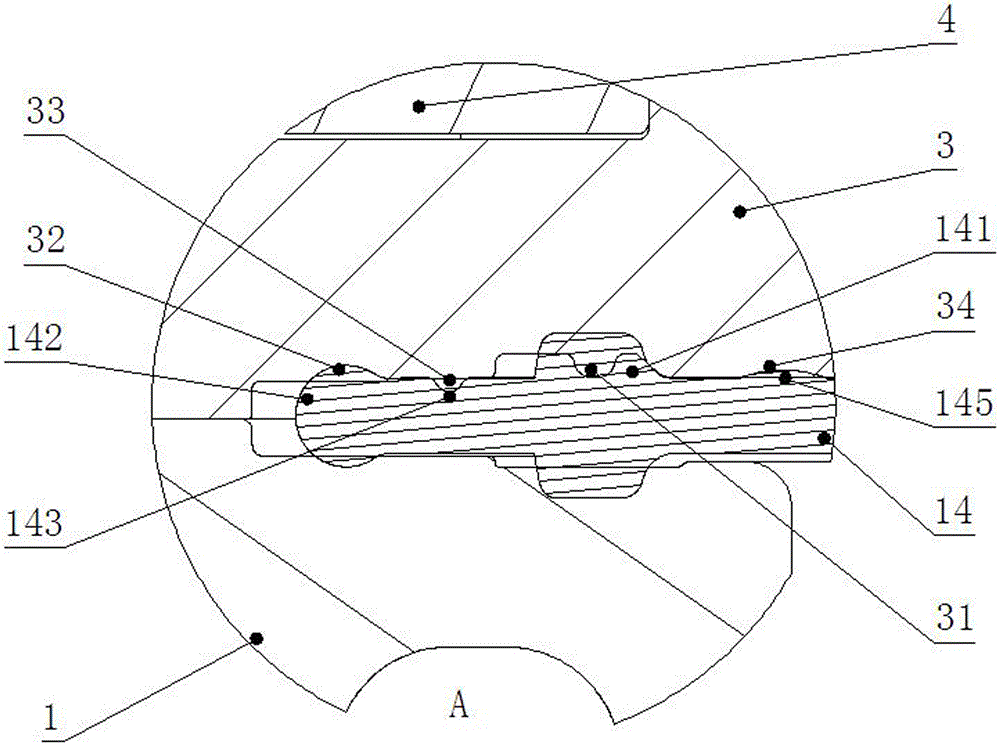

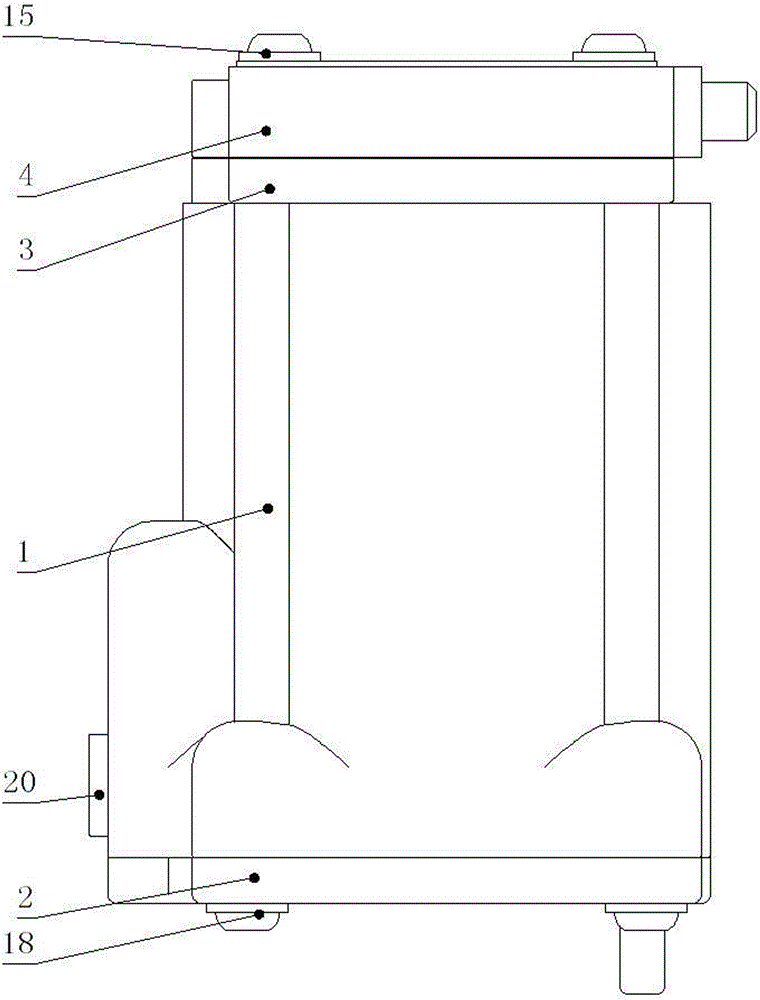

[0022] Such as figure 1 The shown electromagnetic urea pump for exhaust gas treatment of a diesel engine includes a housing 1, the rear end of which is provided with a rear cover 2, and the housing 1 and the rear cover 2 are connected by rear cover screws 18 to ensure that the housing 1 and the rear The installation stability between the covers 2 is also convenient for the assembly and maintenance of the urea pump; an inner cavity is formed between the shell 1 and the rear cover 2, and a push rod 6 is arranged in the inner cavity, and the outer surface of the push rod 6 The snare is provided with a base 7, and the push rod 6 is provided with an armature 8 abutting against the base 7 on the side of the base 7 facing the back cover 2, and the outer ring of the end of the armature 8 facing the side of the back cover 2 is provided with a The outwardly protruding step 81 creates a secondary magnetic circuit between the base 7, the outwardly protruding step 81 of the armature 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com