An equidistantly adjustable adhesive tape cutter fixing device

A fixing device and slitting knife technology, applied in the directions of transportation and packaging, thin material handling, and sending objects, can solve the problems of wasting more time, wasting manpower and time, and large production costs, saving labor and time, Convenient spacing adjustment and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

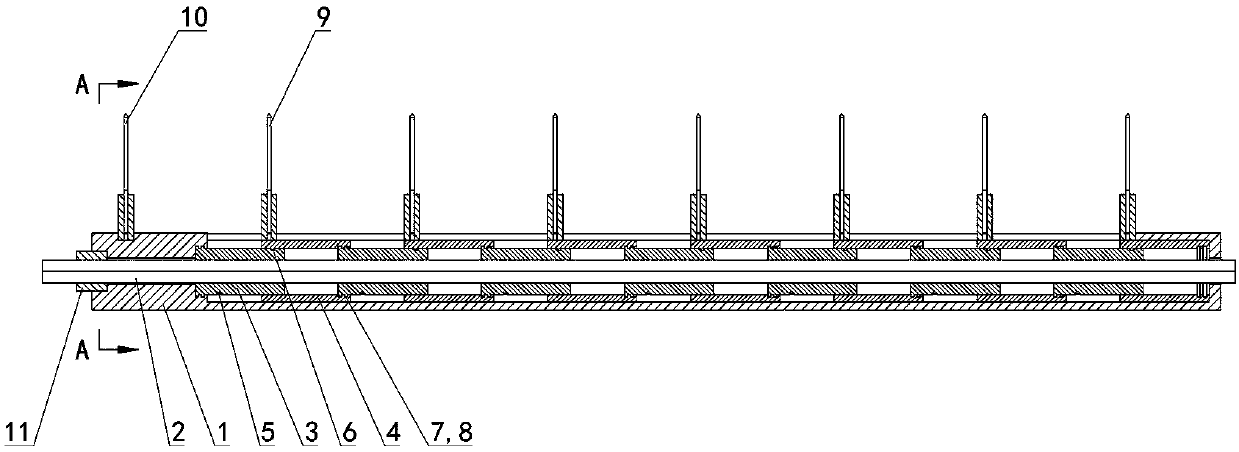

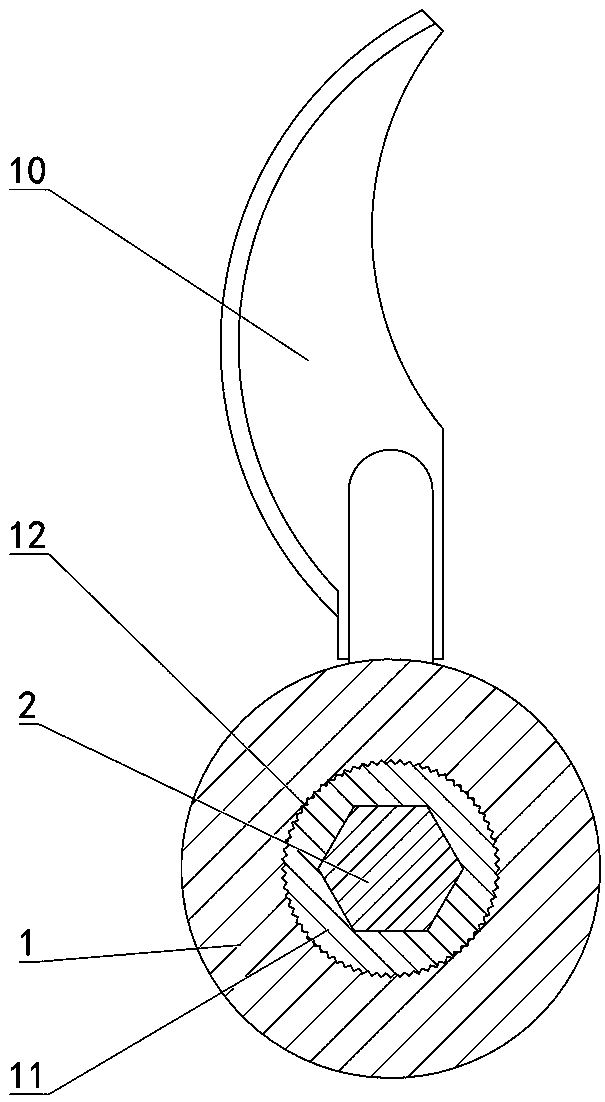

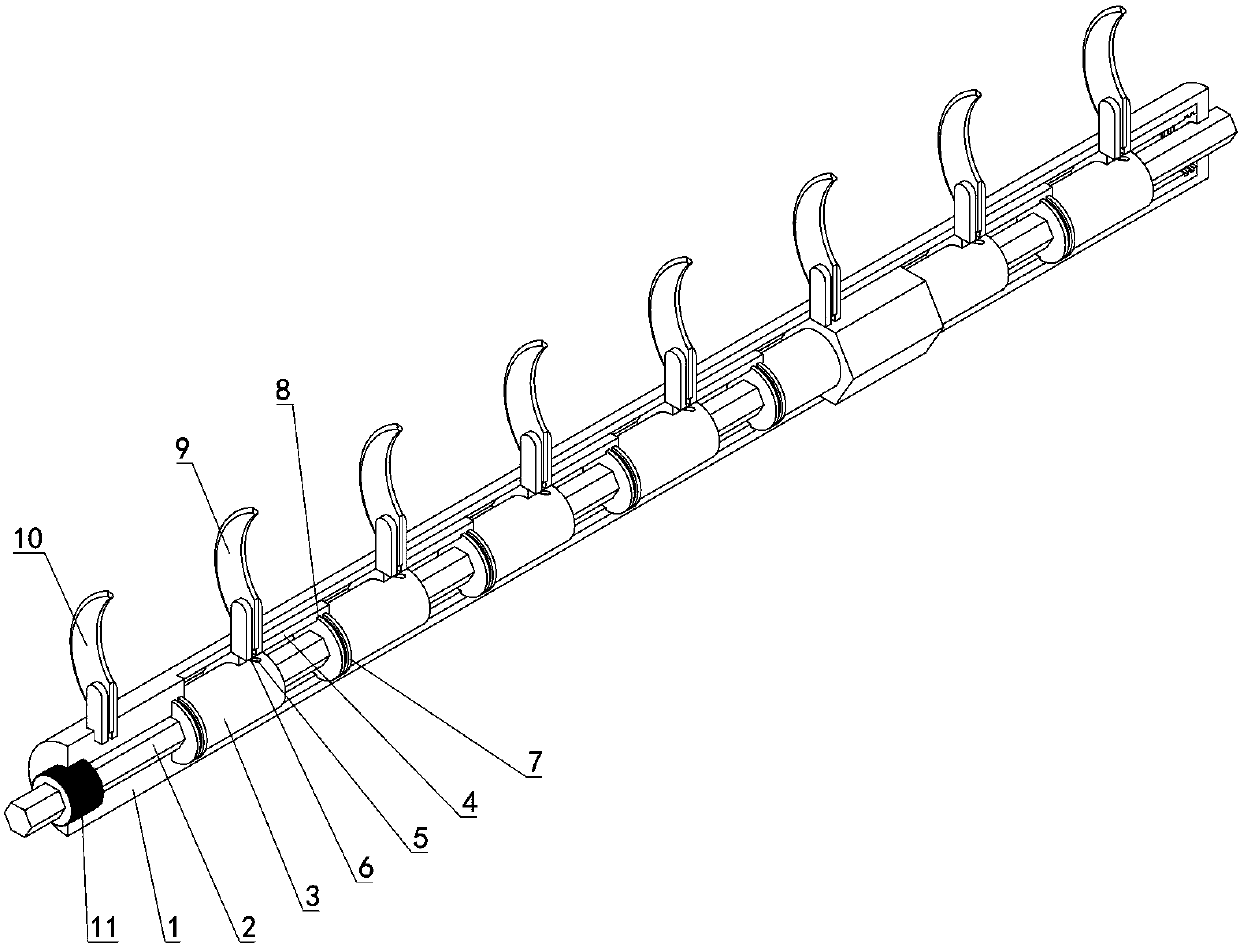

[0017] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Depend on Figure 1 to Figure 6 Provide, the present invention comprises the fixed frame 1 that has the cylindrical cavity that is arranged horizontally, the rotatable rotating shaft 2 that coaxially arranges with the cavity is housed on the fixed frame 1, and a plurality of are placed in the cavity and sequentially arranged on the rotating shaft 2 Connected tool holder unit;

[0019] The tool holder unit includes a camshaft 3 coaxially arranged with the rotating shaft 2 and capable of sliding on the rotating shaft 2. The camshaft 3 is sleeved with a slide block 4 capable of sliding in the cavity. The outer edge of the camshaft 3 is provided with The spiral cam groove 5, the slider 4 is provided with a cam push rod 6 matching the cam groove 5, the cam push rod 6 is placed in the cam groove 5, and when the camshaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com