Grid rolling device

A technology of rolling net and post-rolling net, applied in textiles, textiles, papermaking, looms, etc., can solve the problems that the tension of the rolling net cannot be constant, it is difficult to achieve synchronous movement, the rolling net is easy to slip, etc., and the structure is simple and the movement pace is consistent. , the effect of stable tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

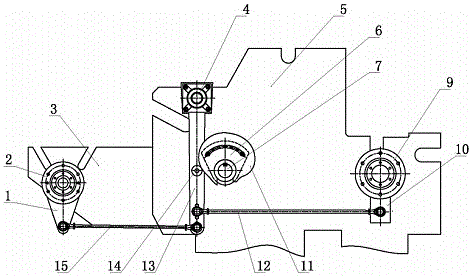

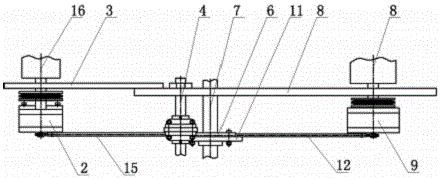

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

[0011] A net rolling device, comprising an inner wall panel 5, a rear net rolling wall panel 3 is fixed relative to the inner wall panel 5, and a main net roll 8 and a rear net roll roll parallel to the axis are rotatably arranged on the inner wall panel 5 16. The shaft end of the main winding roller 8 is provided with the main winding clutch 9, and the rear winding roller 16 is provided with the rear winding clutch 2; a short pillar 4 is fixedly installed perpendicular to the inner wall panel 5, and the upper end of the swing rod 13 is rotatable The ground is connected with the short pillar 4, and the lower end of the fork 13 is provided with two hinge points, one of which is connected to the rotating arm 1 of the rear roll net clutch through the push rod one 15, and the other hinge point is connected to the main hinge point through the push rod two 12. The rotating arm 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com