Combined high-efficiency silage coating machine and use method thereof

A silage and combined technology, which is applied in the field of combined high-efficiency silage coating machines, can solve the problems of inconvenient coating, low coating efficiency, and poor quality, and achieve good coating quality, convenient coating, and Easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

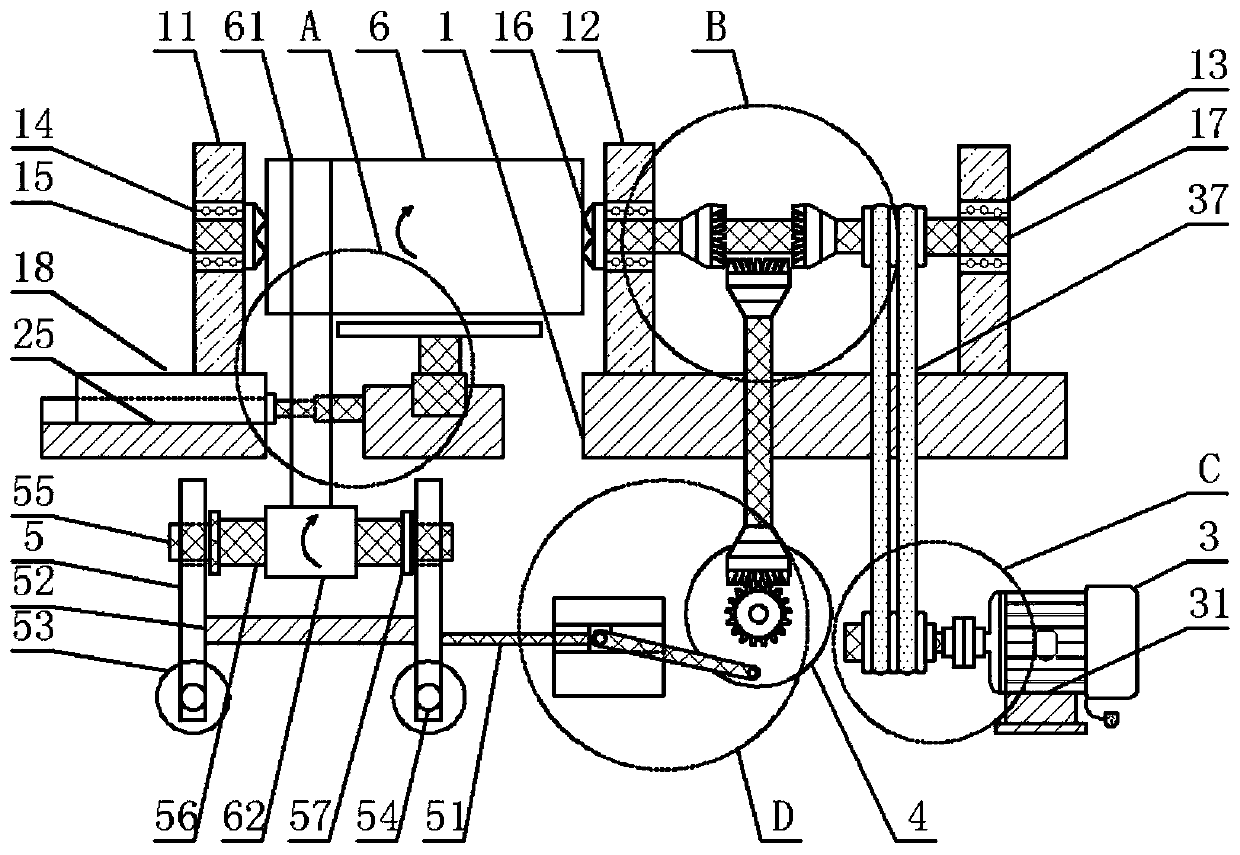

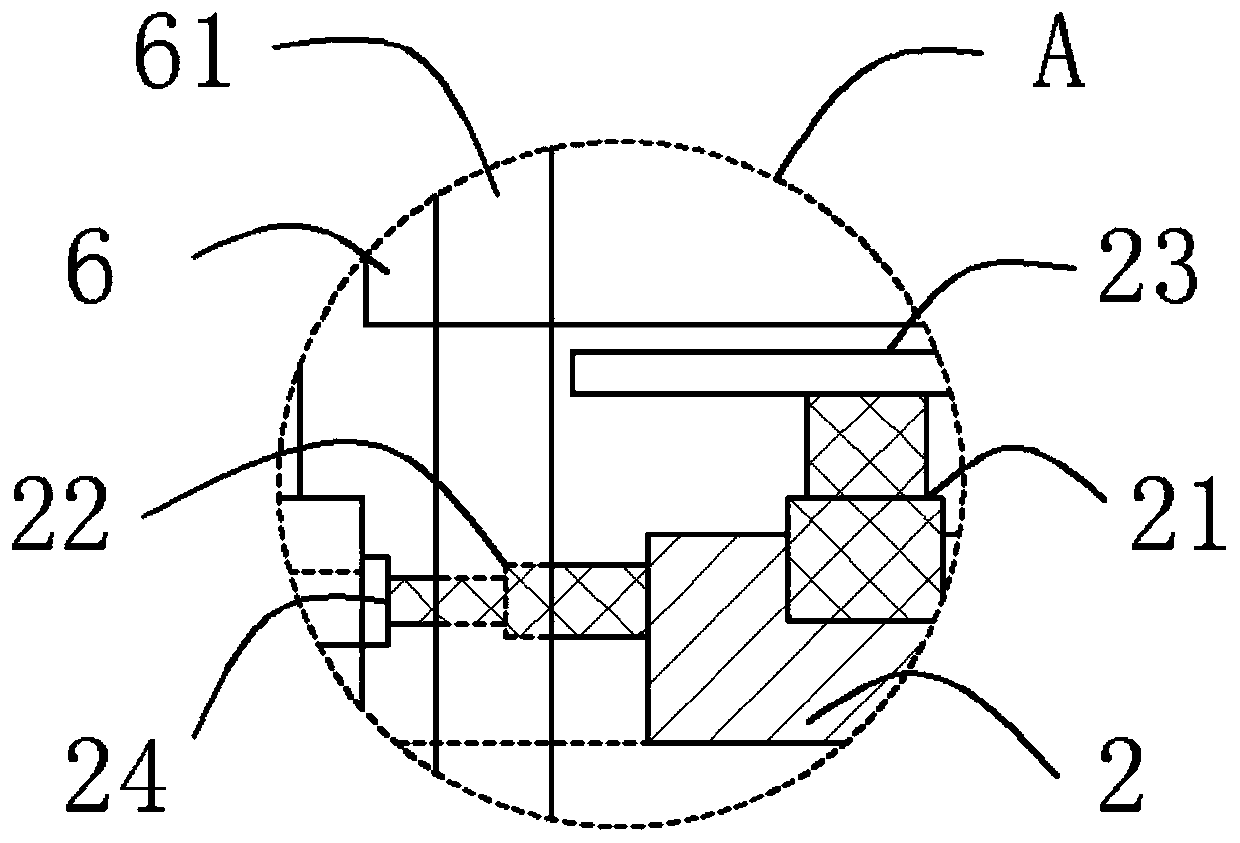

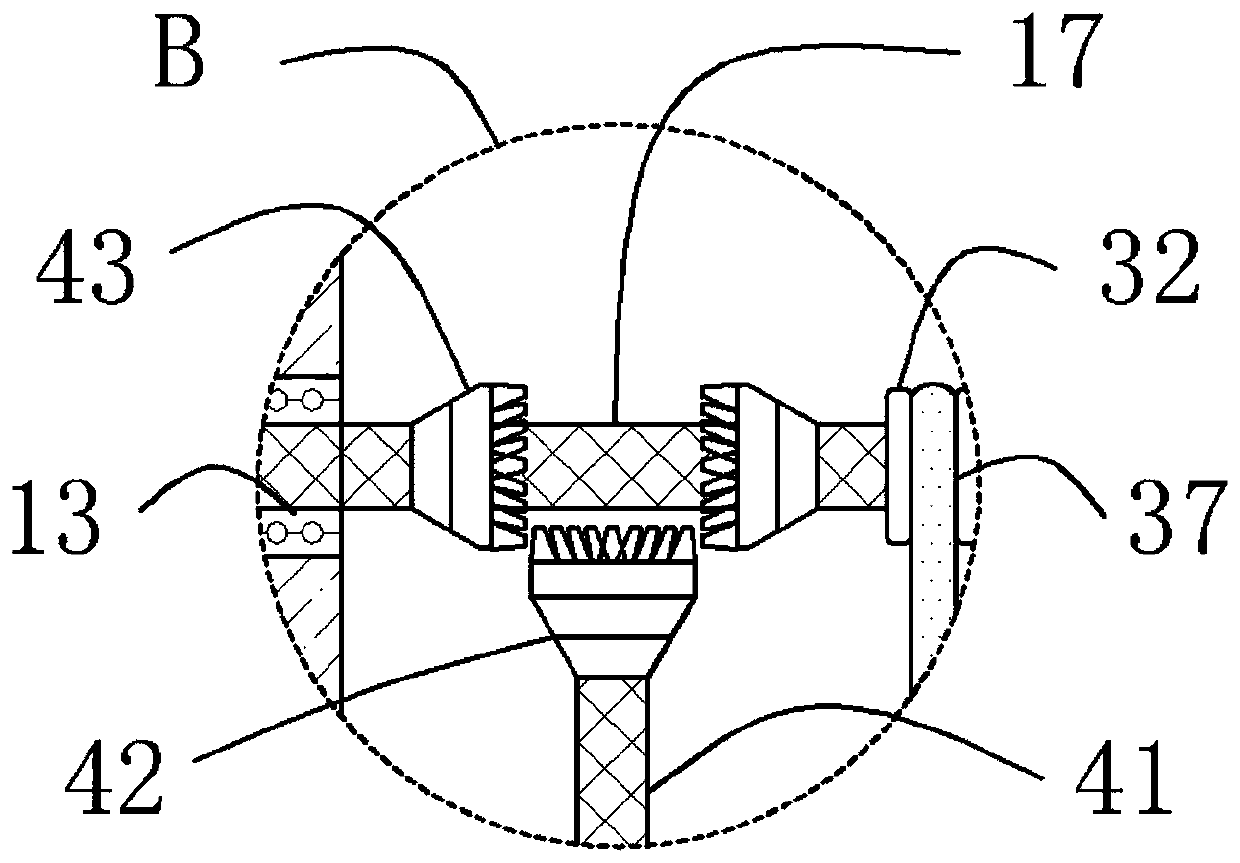

[0036] Embodiment 1: In order to achieve the purpose of coating bales with different shapes and good coating quality and high efficiency, this embodiment provides a combined high-efficiency silage coating machine, see Figure 1-7 , including a base plate 1, a telescopic mechanism, a belt transmission mechanism, a connecting rod assembly, and a moving part. The base plate 1 is a rectangular plate placed horizontally, and a pair of vertical plates 12 are longitudinally provided on the top surface of the base plate 1. The sides of the vertical plates 12 are The center positions are horizontally recessed with first bearing grooves, and the first bearing grooves are provided with first bearings 13, and the two first bearings 13 are horizontally provided with a horizontal axis 17 that runs through both ends; the bottom plate 1 left A telescopic mechanism is provided on the side ground, and the telescopic mechanism contains a hydraulic vertical cylinder 21 and a hydraulic horizontal c...

Embodiment 2

[0046] Embodiment 2: In this embodiment, a method for using a combined high-efficiency silage coating machine is specifically provided, including the following steps:

[0047] Step 1, the first power line, the second power line, and the third power line are respectively electrically connected to the external power supply, and the hydraulic cylinder and the motor are connected to an external control switch, and the vertical movement of the telescopic rod of the hydraulic vertical cylinder 21 and the hydraulic pressure are controlled by the control switch. The lateral movement of the telescopic rod of the horizontal cylinder 22 and the rotation of the motor 3;

[0048] Step 2, place the bale 6 horizontally on the support plate 23, control the hydraulic vertical cylinder 21 telescopic rod to rise, so that the center of the right side of the bale 6 on the support plate 23 is aligned with the gripper at the center of the left side of the vertical plate 12 16. At the same time, cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com