3D (Three-dimensional) printing process intelligent forging casting hammer and 3D printer

A 3D printer and 3D printing technology, applied in the field of 3D printing, can solve the problems of easy deformation, loose internal structure, insufficient compactness, etc., and achieve the effect of eliminating the internal stress of the product, compacting the internal structure, and eliminating the internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

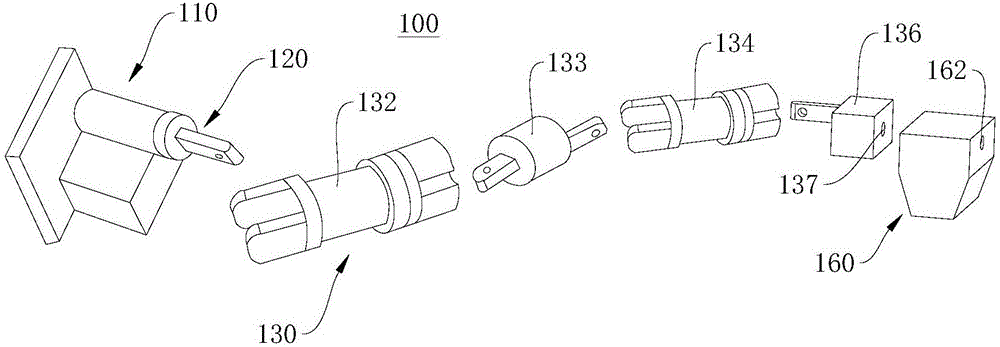

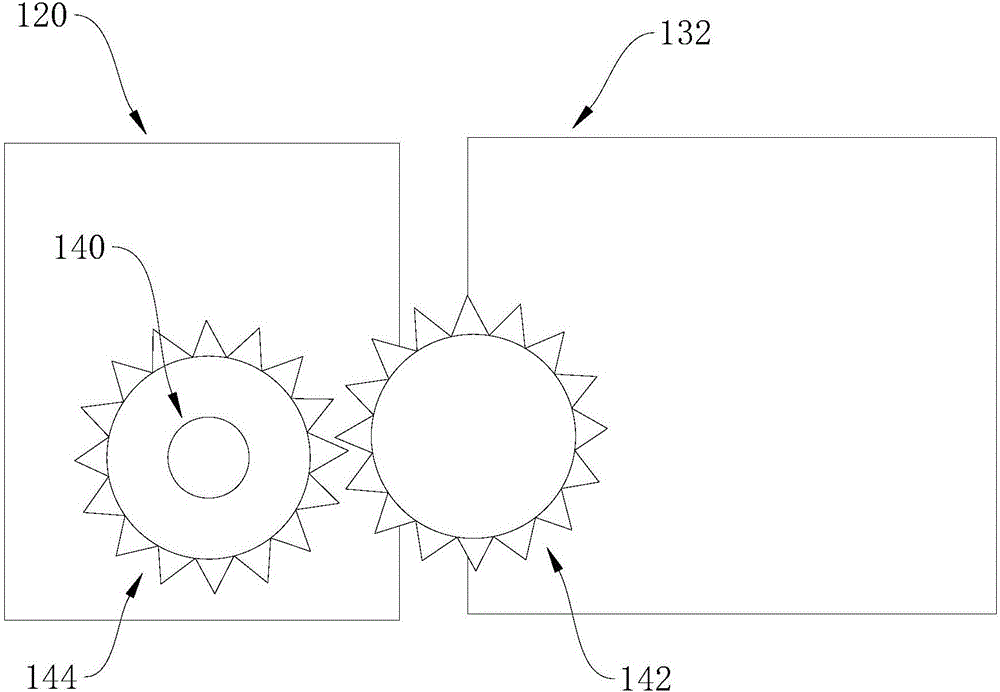

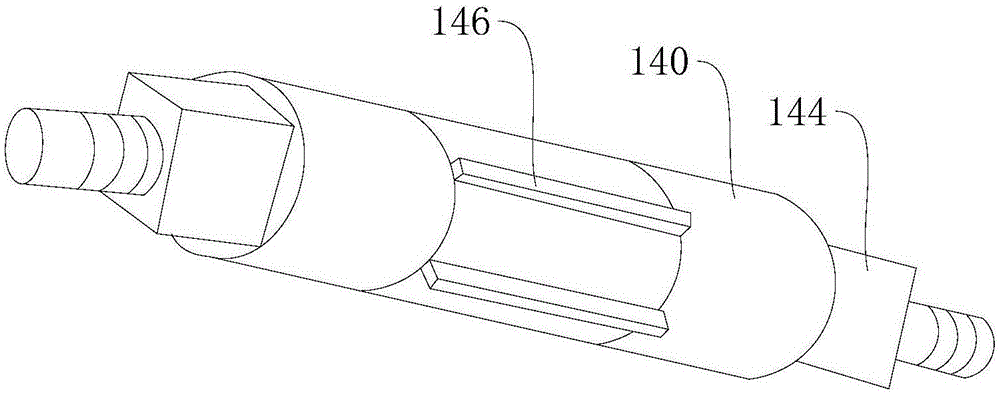

[0033] figure 1 A schematic diagram of the overall structure of the 3D printing process intelligent forging hammer 100 provided by the embodiment of the present invention. Please refer to figure 1 , the present embodiment provides a 3D printing process intelligent forging hammer 100 , which includes a fixed seat 110 , a driving device, a first rotating device, a rotating arm 120 , a mechanical arm 130 and a forging hammer 160 . One end of the rotating arm 120 is rotatably connected to the fixed seat 110 , and the other end is rotatably connected to one end of the mechanical arm 130 . The driving device is connected with the rotating arm 120 and is used to drive the rotating arm 120 to rotate relative to the fixed base 110 so that the mechanical arm 130 rotates relative to the fixed base 110 . The first rotating device is connected with the mechanical arm 130 and is used to drive the mechanical arm 130 to rotate relative to the rotating arm 120 so that the mechanical arm 130 ...

Embodiment 2

[0058] The embodiment of the present invention also provides a 3D printer, and the 3D printer includes the above-mentioned 3D printing technology intelligent forging hammer 100 .

[0059] In this embodiment, the 3D printing process intelligent forging hammer 100 is installed inside the shell of the 3D printer. The fixed base 110 rotates, so that the mechanical arm 130 rotates relative to the fixed base 110 to a position extending away from the product. The first rotating device drives the mechanical arm 130 to rotate relative to the rotating arm 120, so that the mechanical arm 130 rotates vertically relative to the fixed seat 110, so that the mechanical arm 130 drives the forging hammer 160 to extend to the product being processed. After the laser device of the 3D printer processes a certain number of layers of components, the 3D printing process intelligent forging hammer 100 is started. At this time, the forging hammer 160 extends to the product being processed to forge it. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com