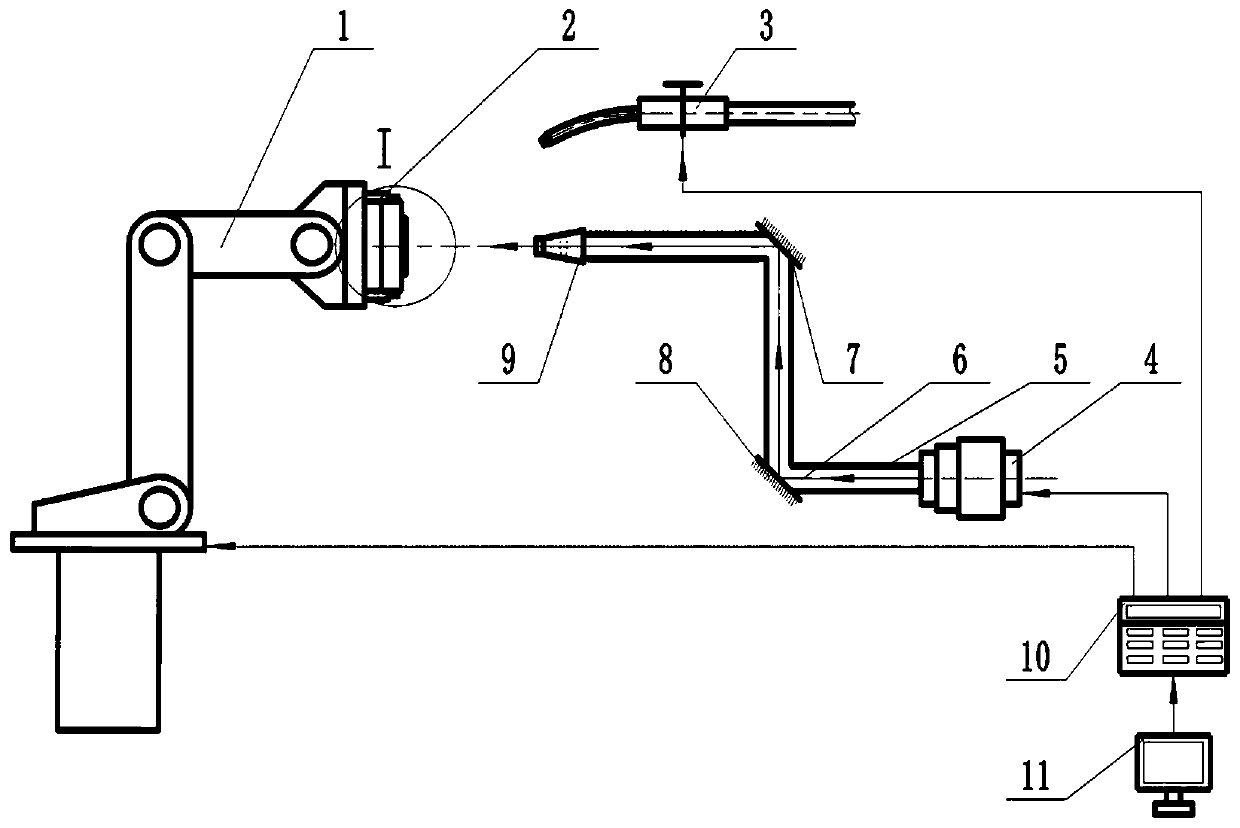

Laser shock forming method and device for straight-wall cylindrical parts

A laser shock, cylindrical part technology, applied in the field of near-net-shape plastic processing of mechanical parts, can solve the problems of small inner circle diameter, restricted application promotion, irregular shock wave pressure field, etc., to achieve convenient position adjustment, safe and reliable operation , The effect of precise and controllable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

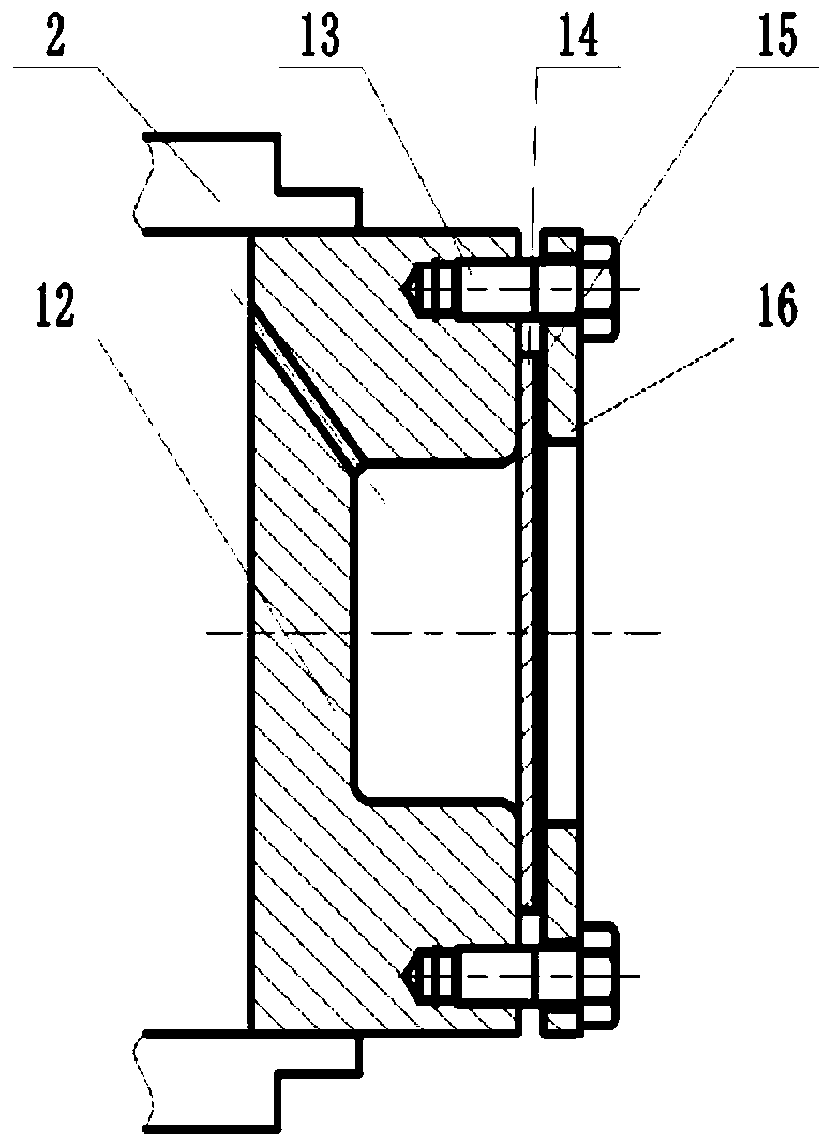

[0033] Embodiment: A flat-bottomed cylindrical cup of aluminum alloy Al2024-T315 is formed by using the method and device of the present invention.

[0034] The size of the die is: the overall outer diameter of the die 12 is 20 mm, and the height is 2 mm; the cavity diameter is 4 mm, the depth is 0.8 mm, the side wall is straight, and the fillet radius of the top and bottom of the cavity is 0.3 mm. The thin metal plate 14 is a circular thin plate, the material of which is Al2024-T315, the thickness of the thin plate is 0.1 mm, and the diameter is φ20 mm. The forming process is as follows:

[0035] The circular sheet is placed directly above the cavity of the die 12 earlier. Coat a layer of black paint with a thickness of 0.1mm as the absorbing layer 15 on the central area of the side of the circular thin plate to be impacted, and place a pressure plate 16. The middle part of the pressure plate 16 is provided with a middle hole with a diameter of φ4mm, and the bolt 13 is pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com