A comprehensive protection control system and method for integrating high-voltage power distribution and equipment operation

A comprehensive protection, high-voltage power distribution technology, applied in pump control, mechanical equipment, emergency protection circuit devices, etc., can solve the problems of low-voltage equipment power supply protection, instability, and inability to program chips, and achieve fast protection action function, good Protective effect and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

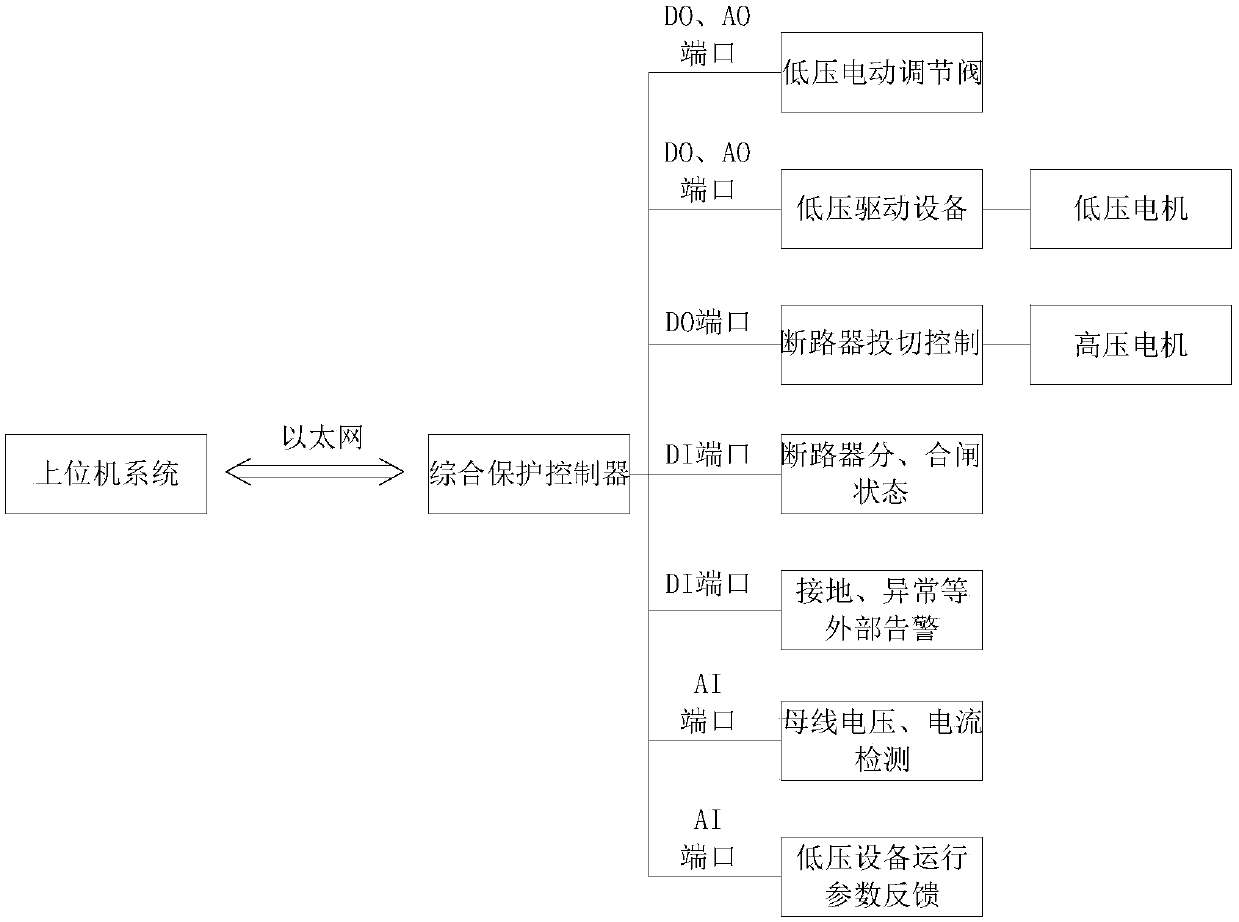

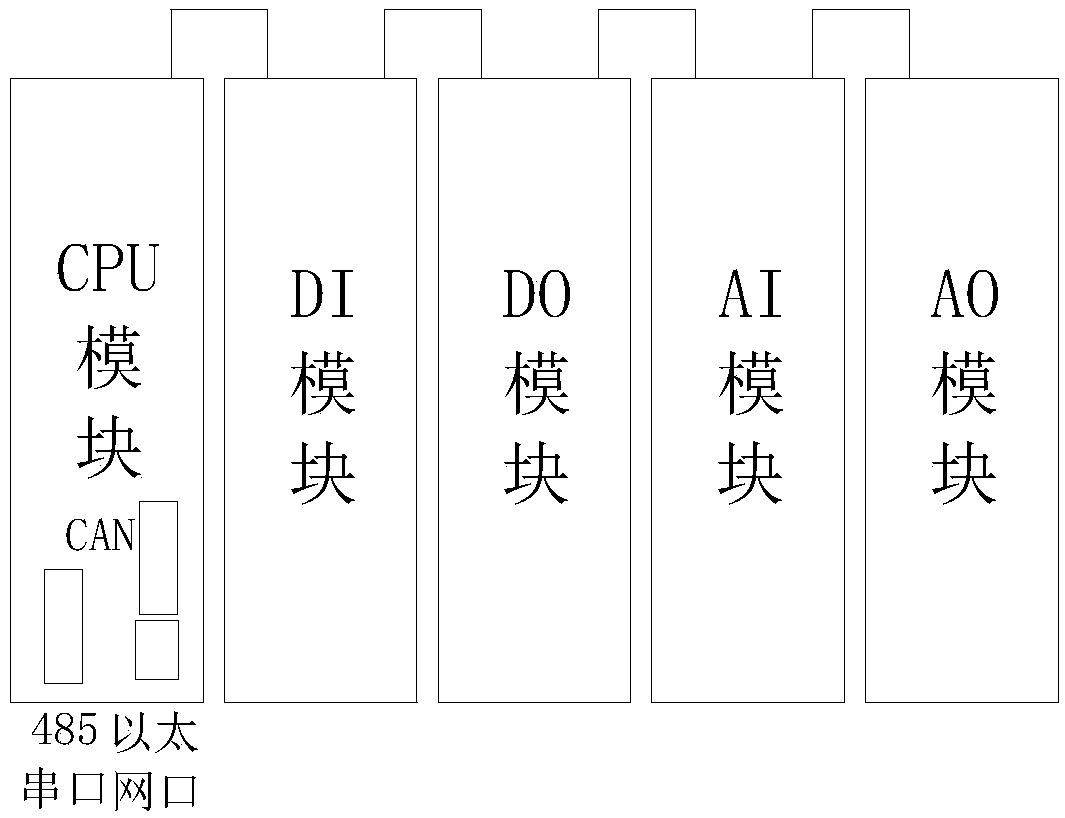

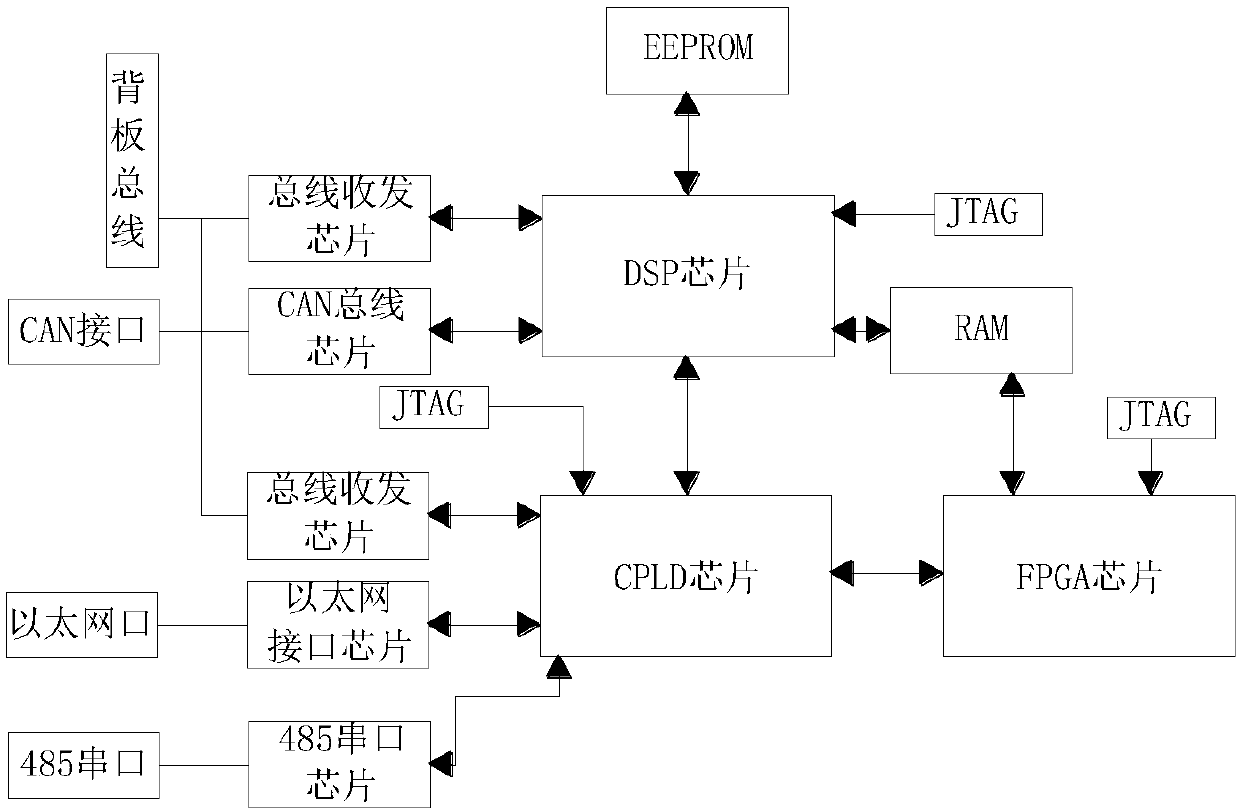

Method used

Image

Examples

specific Embodiment 1

[0049] Specific embodiment 1. When a fault is found at the high-voltage power distribution bus end, such as when an accident trips,

[0050] 1. Cut off the high-voltage power supply or switch to the backup power supply;

[0051] 2. Cut off the power supply circuit of low-voltage key equipment (such as important water pumps and fans belonging to the primary power supply load) at the same time and switch to the backup power supply in time.

specific Embodiment 2

[0052] Embodiment 2. When the high-pressure water pump or fan is started, that is, before the high-voltage circuit breaker is closed, the valve at the outlet of the high-pressure water pump or fan is opened first, and then the start-up control is performed.

specific Embodiment 3

[0053] Embodiment 3: When the system detects that the valve at the outlet of the high-pressure water pump or fan is closed due to failure, immediately disconnect the power supply of the high-pressure water pump or fan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com