Method for simply and efficiently determining content of lead in gold concentrate

A lead content, gold concentrate technology, applied in measuring devices, color/spectral property measurement, chemical analysis by titration, etc. The effect of experiment efficiency and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

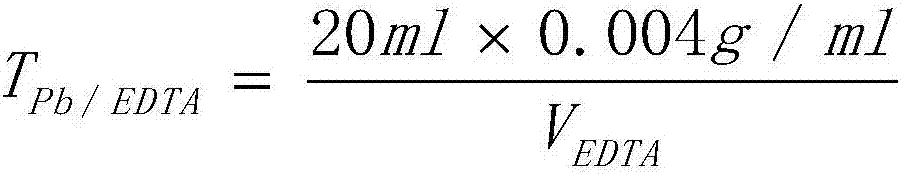

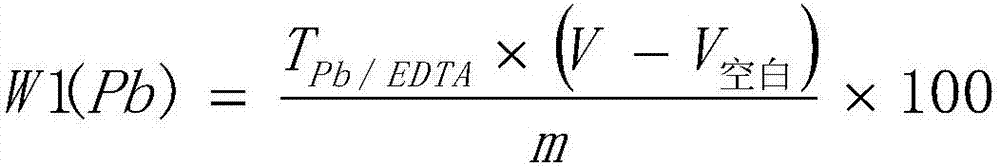

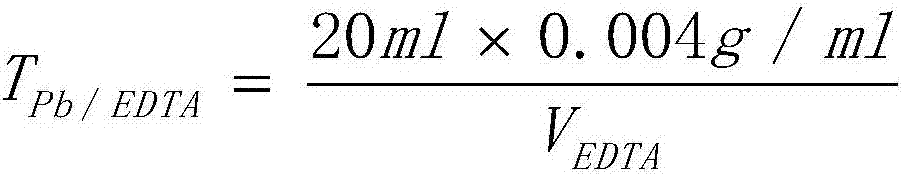

Method used

Image

Examples

Embodiment 1

[0067] (1) Weigh 0.27g of the ore sample to be tested, put it in a 400mL beaker, add water to moisten it, add 0.5g of ammonium fluoride, add 20mL of saturated nitric acid-potassium chlorate solution, cover with a watch glass, and heat it on an electric furnace until NO 2 The smoke was exhausted, and the sample was completely digested.

[0068] (2) Take off the beaker and cool to room temperature, add 10mL concentrated H 2 SO 4 , put it on the electric furnace to heat, steam until thick white smoke is emitted for 5 minutes, remove the beaker and cool to room temperature, add 100mL of water, put it on the electric stove, heat to boiling, and boil slightly for 10 minutes;

[0069] (3) Remove the beaker, let it cool slightly, add 5mL of absolute ethanol, and let stand for 60min;

[0070] (4) Use double-layer slow quantitative filter paper to filter, use sulfuric acid lotion (2+98) to wash the precipitate, and drop the washing solution on the quantitative filter paper stained wit...

Embodiment 2

[0090] (1) Weigh 0.30g of sample, put it in a 400mL beaker, add water to moisten it, add 0.5g of ammonium fluoride, add 20mL of saturated nitric acid-potassium chlorate solution, cover with a watch glass, and heat it on an electric furnace to NO 2 The smoke was exhausted, and the sample was completely digested.

[0091] (2) Take off the beaker and cool to room temperature, add 10mL concentrated H 2 SO 4 , put it on the electric furnace to heat, steam until thick white smoke is emitted for 5 minutes, remove the beaker and cool to room temperature, add 100mL of water, put it on the electric stove, heat to boiling, and boil slightly for 10 minutes;

[0092] (3) Remove the beaker, let it cool slightly, add 5mL of absolute ethanol, and let stand for 60min;

[0093] (4) Use double-layer slow quantitative filter paper to filter, use sulfuric acid lotion (2+98) to wash the precipitate, and drop the washing solution on the quantitative filter paper stained with potassium thiocyanate ...

Embodiment 3

[0113] (1) Weigh 0.28g of the sample, put it into a 400mL beaker, add water to moisten it, add 0.5g of ammonium fluoride, add 20mL of saturated nitric acid-potassium chlorate solution, cover with a watch glass, and heat it on the electric furnace to NO 2 The smoke was exhausted, and the sample was completely digested.

[0114] (2) Take off the beaker and cool to room temperature, add 10mL concentrated H 2 SO 4 , put it on the electric furnace to heat, steam until thick white smoke is emitted for 5 minutes, remove the beaker and cool to room temperature, add 100mL of water, put it on the electric stove, heat to boiling, and boil slightly for 10 minutes;

[0115] (3) Remove the beaker, let it cool slightly, add 5mL of absolute ethanol, and let stand for 60min;

[0116] (4) Use double-layer slow quantitative filter paper to filter, use sulfuric acid lotion (2+98) to wash the precipitate, and drop the washing solution on the quantitative filter paper stained with potassium thioc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com