Resilience force test method and resilience force test tool

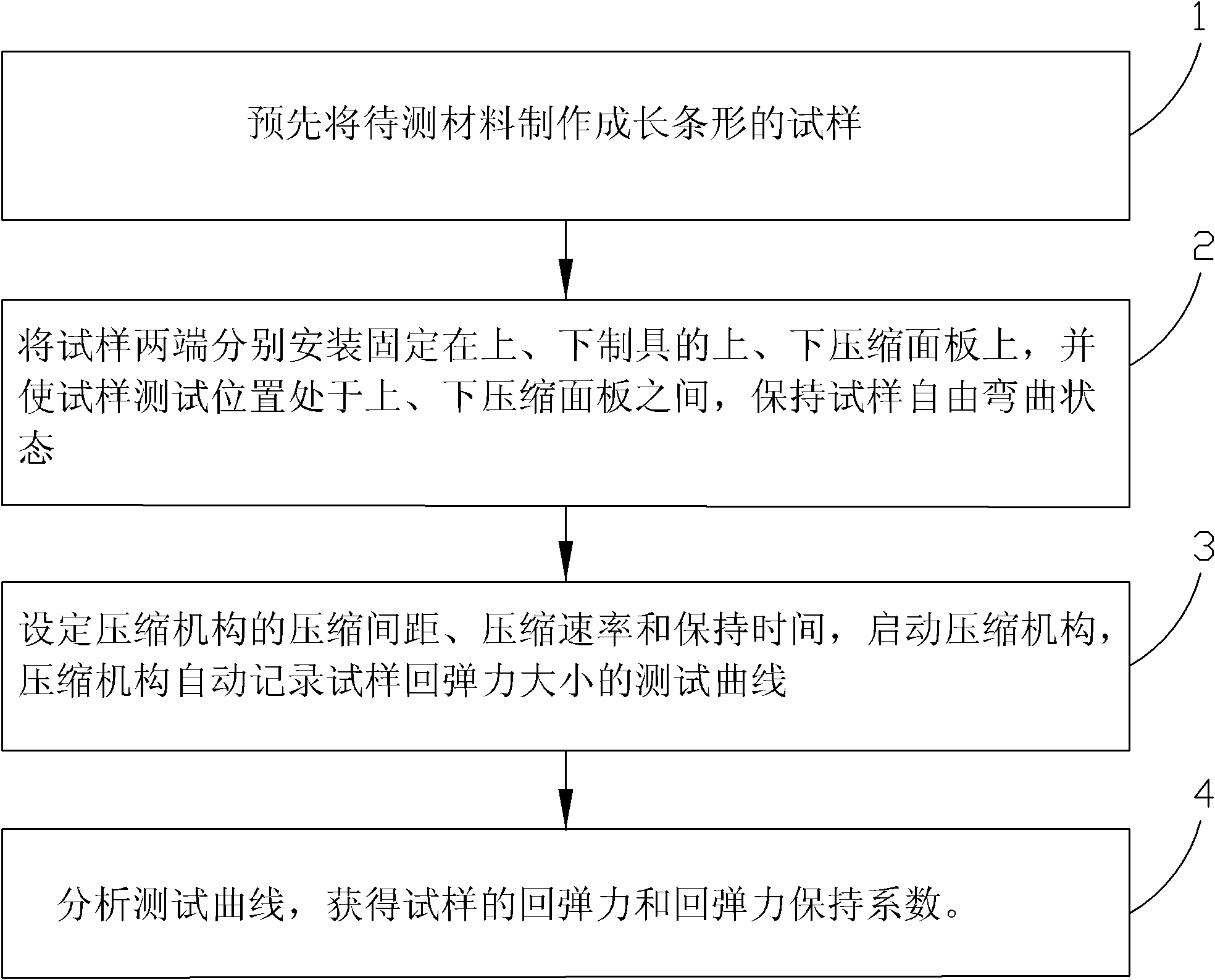

A test method and technology of resilience, applied in the direction of applying stable bending force to test material strength, test material hardness, measuring device, etc., can solve the problems of roughness and great influence of the bending amount of the sample, and achieve a large test range , Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

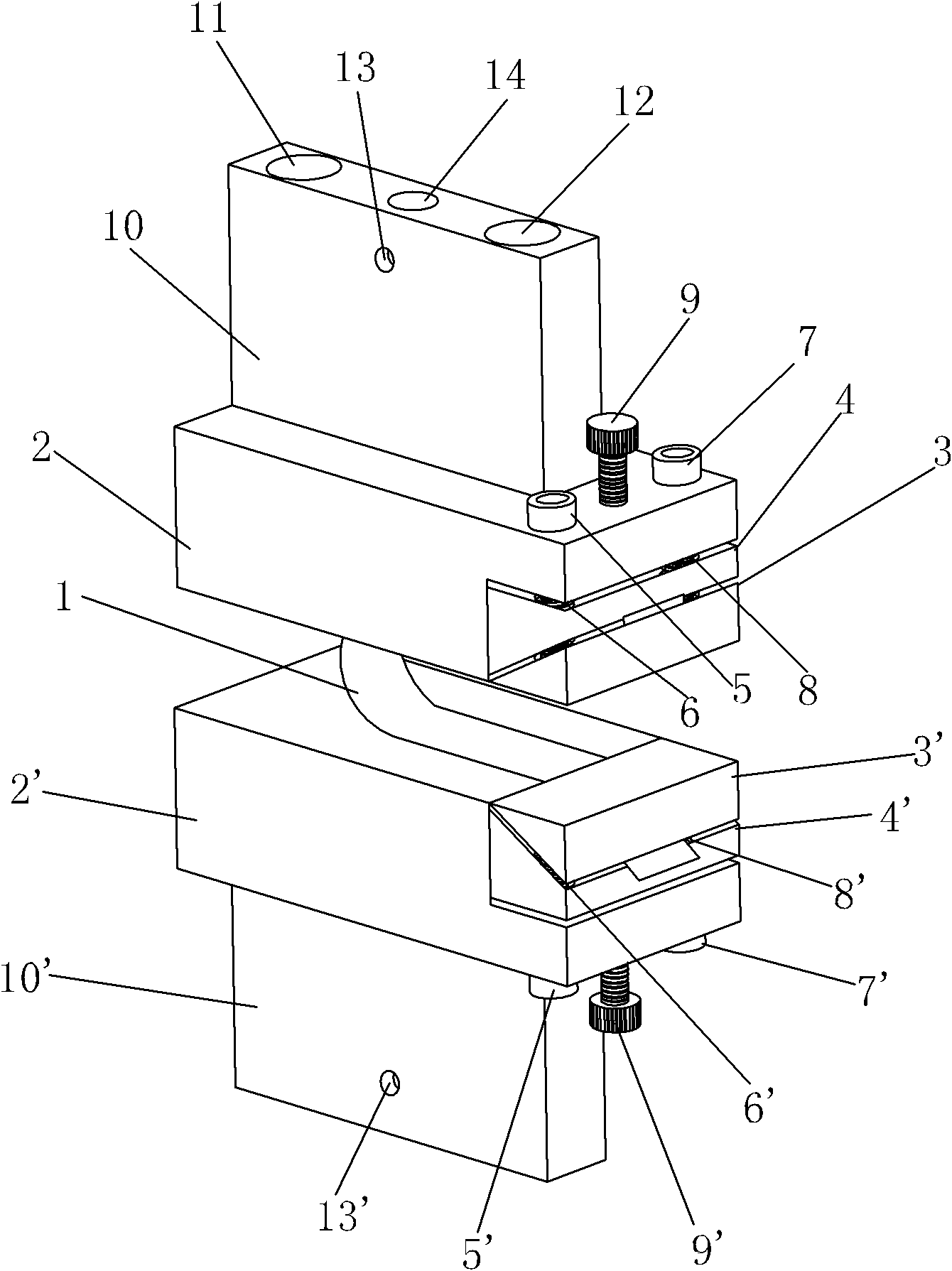

Examples

Embodiment 1

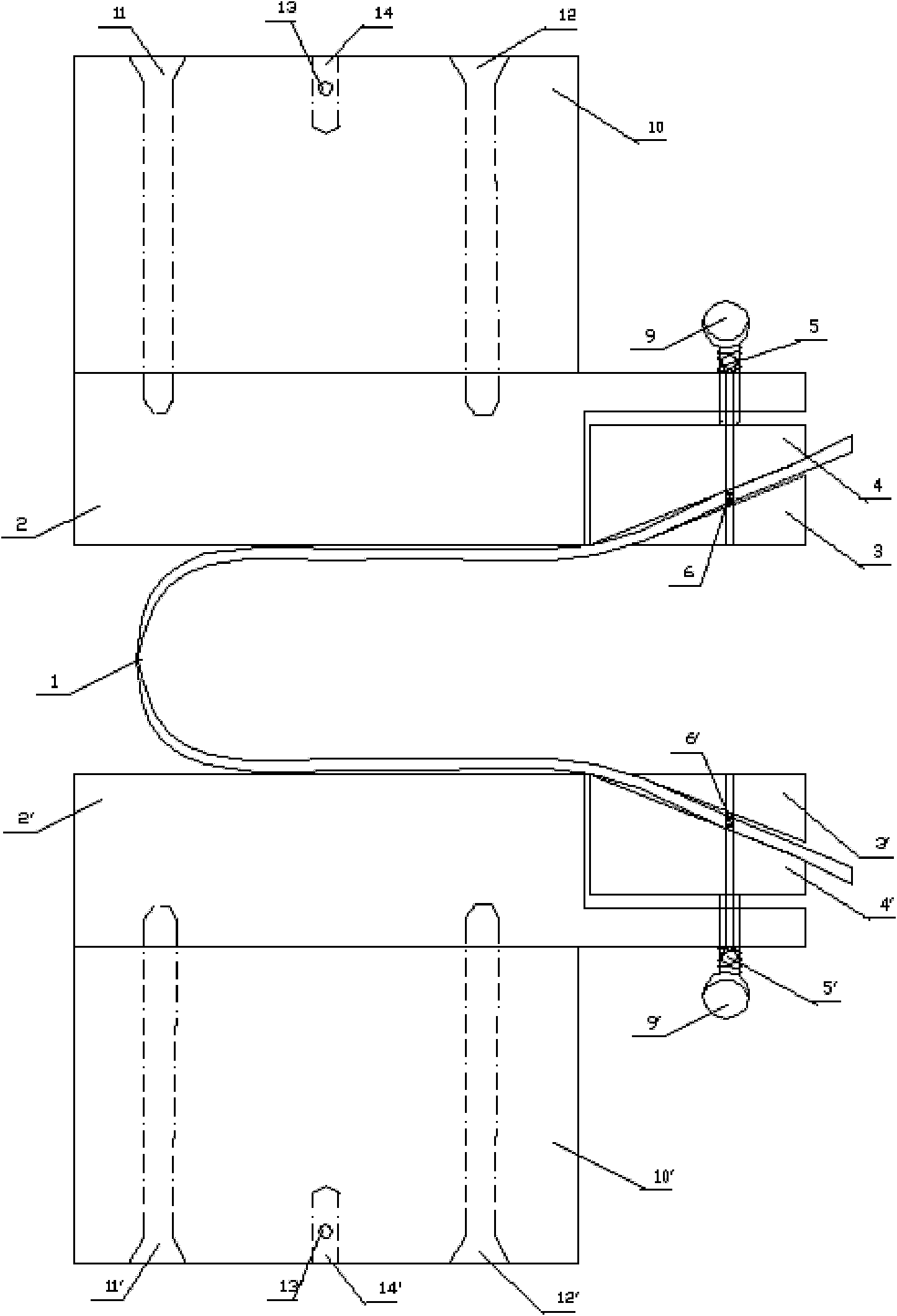

[0044] Take flexible copper-clad laminates A and B with the same specifications and different formulations, and after etching the copper foil, make a strip-shaped sample of 15mm×120mm.

[0045] Set the initial spacing of the compression mechanism to 30mm, the final spacing to 1mm, the compression rate to 50mm / min, and the holding time to 30s.

[0046] Fix the sample in the resilience test tool of the present invention respectively, start the test program, the compression mechanism automatically records the compression test resilience test curve, and analyzes the test curve to obtain the resilience and resilience retention coefficient respectively as shown in Table 1.

[0047] Table 1 Resilience and resilience retention coefficient of flexible copper clad laminates with different formulations

[0048] sample

[0049] Both the resilience and resilience retention coefficient of sample A are slightly smaller than that of sample B, so the softness of sample A is better th...

Embodiment 2

[0051] Take flexible copper-clad laminates C and D of different manufacturers with the same specification, and after etching the copper foil, make a strip-shaped sample of 15mm×120mm.

[0052] Set the initial spacing of the compression mechanism to 30mm, the final spacing to 1mm, the compression rate to 50mm / min, and the holding time to 30s.

[0053] Fix the sample in the resilience test tool of the present invention respectively, start the test program, and the compression mechanism automatically records the compression test resilience test curve, and analyzes the test curve to obtain the resilience and resilience retention coefficient as shown in Table 2.

[0054] Table 2 Resilience and resilience retention coefficient of flexible copper clad laminates from different manufacturers

[0055] sample

[0056] The resilience of samples C and D are the same, but the resilience retention coefficient of sample C is smaller than that of sample D, so the flexibility of sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com