Middle open type translation double-sealed rectangular gate valve

A double-seal and split-open technology, which is applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems that one-way sealing cannot be guaranteed, and achieve the effect of large specifications, small opening torque and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described with reference to the accompanying drawings and embodiments.

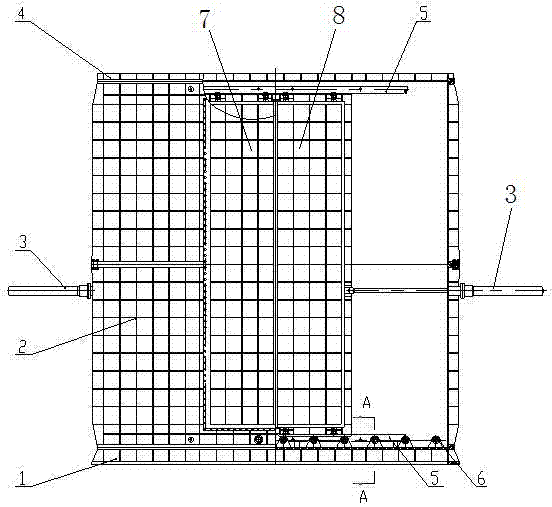

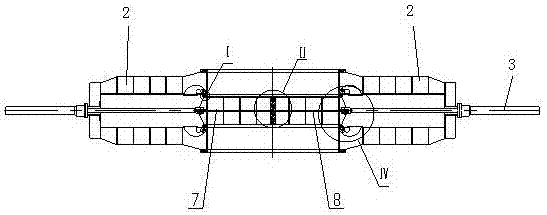

[0025] Figure 1-6 Middle: There are two rows of 20 rollers 6 evenly distributed on the base 1. The valve body 2 is a rectangular frame. One end is respectively connected with the left and right sides of the valve body 2, the left valve plate 7 and the right valve plate 8 are rectangular frames, the left valve plate 7 and the right valve plate 8 are in the valve body 2 and respectively on both sides of the valve body 2, the two The other end of each driving device 3 is respectively connected with the left valve plate 7 and the right valve plate 8, the upper and lower parts of the valve body 2 are respectively connected with a shift fork driving device 12, and the front and rear parts of the inner cavity of the valve body 2 are respectively connected with a The sealing ring 9 is evenly distributed along the edge of the inner cavity of the valve body 2 and is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com