Reinforcement and detection method for old and new roadbed combined part

A detection method and joint technology, which are applied in basic structure engineering, basic structure testing, roads, etc., can solve the problems of different filling quality requirements, excessive settlement after construction, waste and other problems, so as to reduce post-construction settlement and improve roadbed. Effects of strength and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

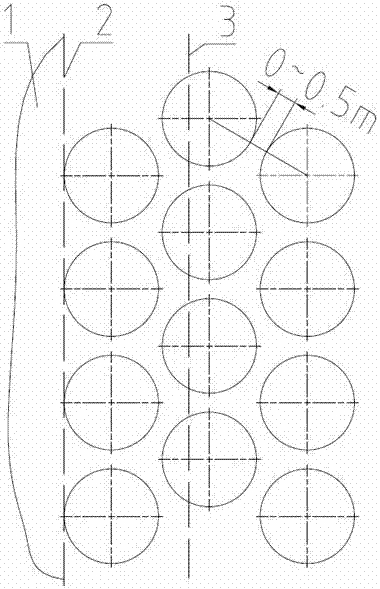

[0036] For highways in hilly areas, the roadbed is filled with gravel soil, and the junction of the old and new roads on the embankment that has passed the layered rolling test is reinforced with a 36 kJ high-speed hydraulic compactor. 6-12 hammers were used in the test, and the settlement was detected every 3 hammers. The average settlement of each test point was 26mm at 9 hammers, which was close to the test results of the adjacent new roadbed. The roadbed filling in this test section is excellent, the early construction quality is good, and the lower part of the roadbed is hard. The official construction is based on a step width of 1.2m, a single point of 9 hammers, a center distance of 1.5m between the ramming points (0.5m from the edge of the ramming point), and two rows of ramming points. , reinforce once every 2m of filling.

Embodiment 2

[0038] The expressway in the plain and hilly area has great differences in geological conditions, and it is divided into two test sections.

[0039] A test section is located in the micro-hill area, the filler is fine-grained soil, and the lower embankment is qualified for layered rolling. After reinforcement with a 32t vibratory roller, continue to use a 36 kJ high-speed hydraulic compactor for secondary reinforcement. The settlement of the last 3 hammers is not greater than the requirement of 40mm. The construction is carried out according to the step width of 1.2m (the step is too wide to increase the cost), 12 hammers in a single point, the center distance of the tamping point is 1.2m (the distance between the edge of the tamping point is 0.2m), three rows of tamping points, every 2m of filling is reinforced once.

[0040] The B test section is located in the plain area, the filler is silty clay with low liquid limit, the groundwater is abundant, and the lower embankment i...

Embodiment 3

[0042] The tertiary road will be expanded into a second-class road, widened by ~1.5m on one side, and the filler will be ungraded coal gangue with a filling depth of 80cm, which will be pulverized and compacted at one time with a 36kJ high-speed hydraulic tamping machine. After the test, the settlement of the 3 hammers after 6 hammer hours meets the requirement of not more than 30mm, and then it is leveled and rolled to pass. The distance between the edges of the construction tamping points is 0, and the tamping points are allowed to partially overlap and the two rows are staggered.

[0043] The method for reinforcing the junction of old and new roadbeds provided by the invention is suitable for roads of different grades and other roads, directly improves the strength and uniformity of roadbeds, and avoids or reduces uneven settlement of old and new roadbeds. The detection and evaluation method provided by the invention is simple and easy to implement , which directly correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com