Lead recycling method and device for perovskite battery

A perovskite battery and lead recovery technology, applied in the field of photovoltaics, to avoid lead pollution, simple and easy structure, and improve the effect of effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

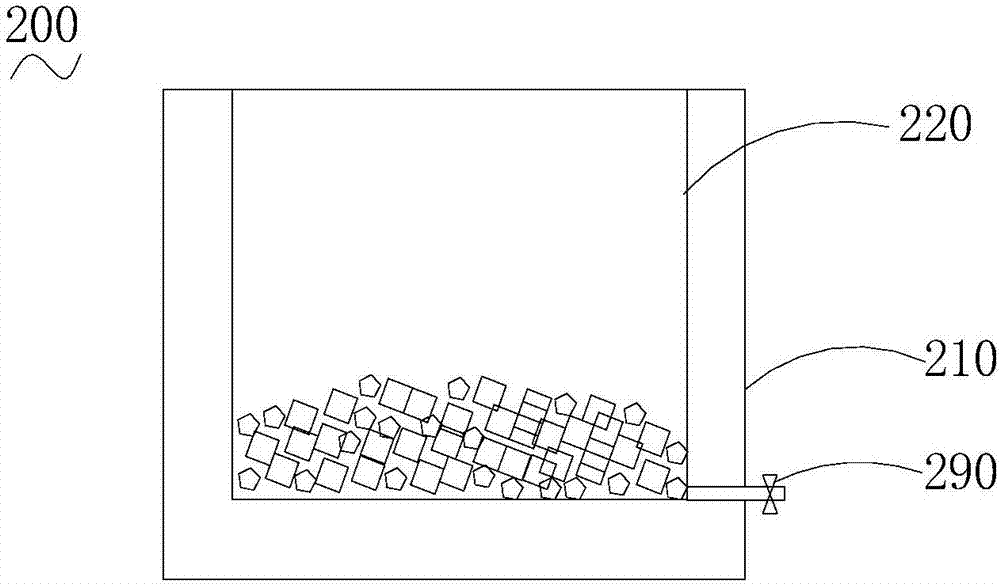

[0071] Break the perovskite cell into about 1cm 3 of pieces.

[0072] 3000 g of the above fragments were soaked in 2 L soaking solution (DMSO) at 80° C. for 6 h. Then filter to obtain lead-containing separation liquid.

[0073] Add 0.10 g of sodium sulfide to 2 L of lead-containing separation liquid, precipitate for 0.5 h, let stand, and filter to obtain 0.30 g of PbS solid.

[0074] The lead recovery was calculated to be 97%.

Embodiment 2

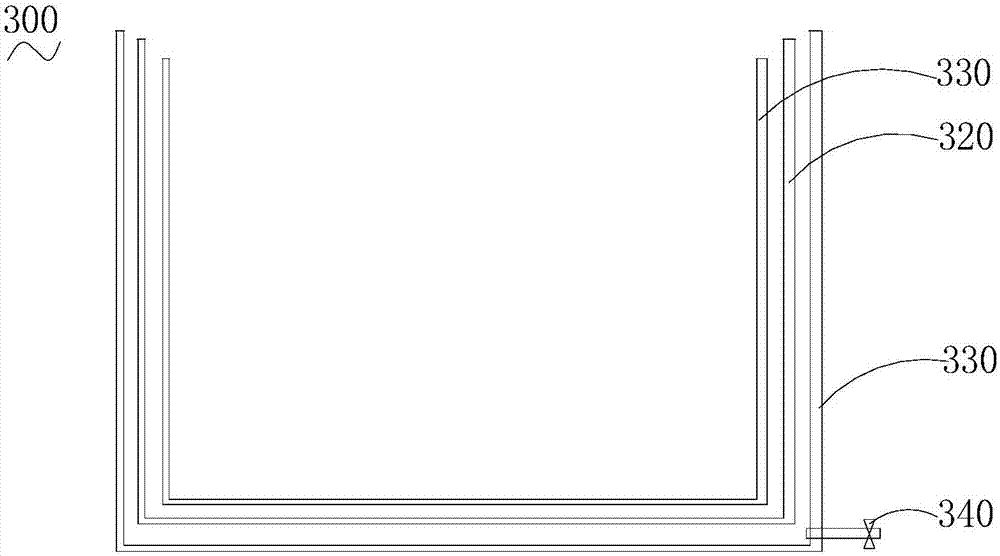

[0076] It is basically the same as Example 1, except that 2L of lead-containing separation solution is poured into the electrolysis mechanism, and then the conductive electrolyte choline chloride is added thereto. The lead foil was used as the working electrode, the carbon electrode was used as the counter electrode, and the working electrode was connected to a voltage of -0.9V.

[0077] Metallic lead is recovered at the cathode. The recovery rate of lead is 97%. The concentration of Pb in the electrolyte drops below 1% of the original concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com