A special viscosifier for shield synchronous grouting material

A simultaneous grouting and tackifier technology, applied in the field of tunnel construction, to achieve the effects of good stretchability, improved water dispersion resistance, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

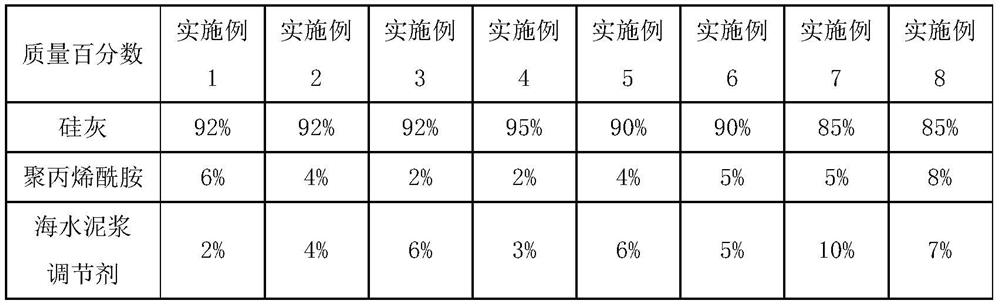

[0025] As shown in Table 1, the synchronous grouting material tackifier consists of the following components by weight ratio:

[0026] Silica fume 92%; polyacrylamide 6%; seawater slurry conditioner 2%;

[0027] Among them: the specific surface area of silica fume is 15000-20000m 2 , the particle size is above 3000 mesh, the molecular weight of polyacrylamide is 6-12 million, the seawater slurry conditioner is the seawater slurry conditioner disclosed in the patent number ZL 2014 1 0036474.1, the molecular weight is 2×10 6 ~1.5×10 7 .

Embodiment 2

[0029] As shown in Table 1, the synchronous grouting material tackifier consists of the following components by weight ratio:

[0030] Silica fume 92%; polyacrylamide 4%; seawater slurry conditioner 4%;

[0031] Among them: the specific surface area of silica fume is 15000-20000m 2 , the particle size is above 3000 mesh, the molecular weight of polyacrylamide is 6-12 million, the seawater slurry conditioner is the seawater slurry conditioner disclosed in the patent number ZL 2014 1 0036474.1, the molecular weight is 2×10 6 ~1.5×10 7 .

Embodiment 3

[0033] As shown in Table 1, the synchronous grouting material tackifier consists of the following components by weight ratio:

[0034] Silica fume 92%; polyacrylamide 2%; seawater slurry conditioner 6%;

[0035] Among them: the specific surface area of silica fume is 15000-20000m 2 , the particle size is above 3000 mesh, the polyacrylamide molecular weight is 6-12 million, the seawater slurry conditioner is the seawater slurry conditioner disclosed in the patent number ZL 2014 1 0036474.1, the molecular weight is 2×10 6 ~1.5×10 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com