Multi-tower pressure swing adsorption grading flushing device and method

A pressure swing adsorption and flushing device technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of poor regeneration effect and short flushing time, and achieve good regeneration effect, long regeneration time, and control The effect of impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

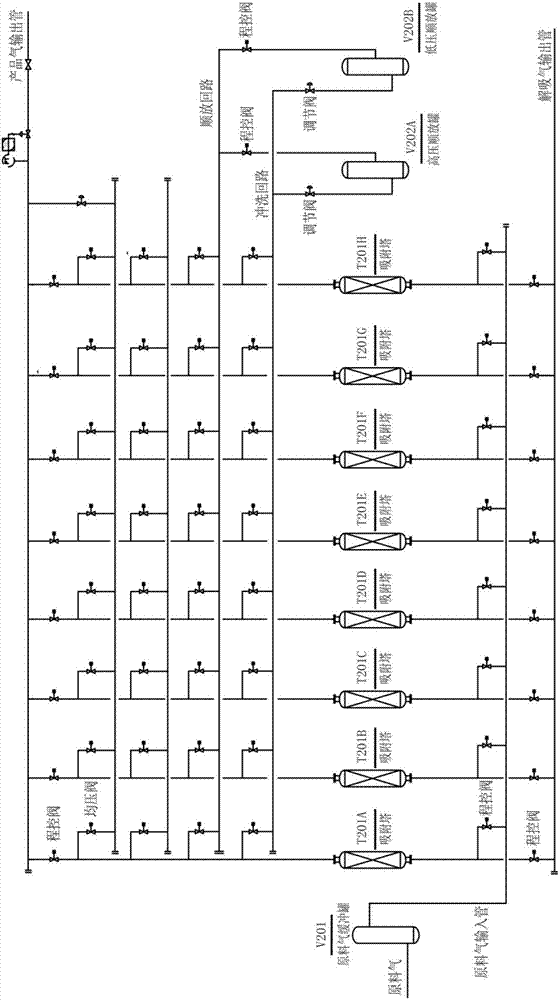

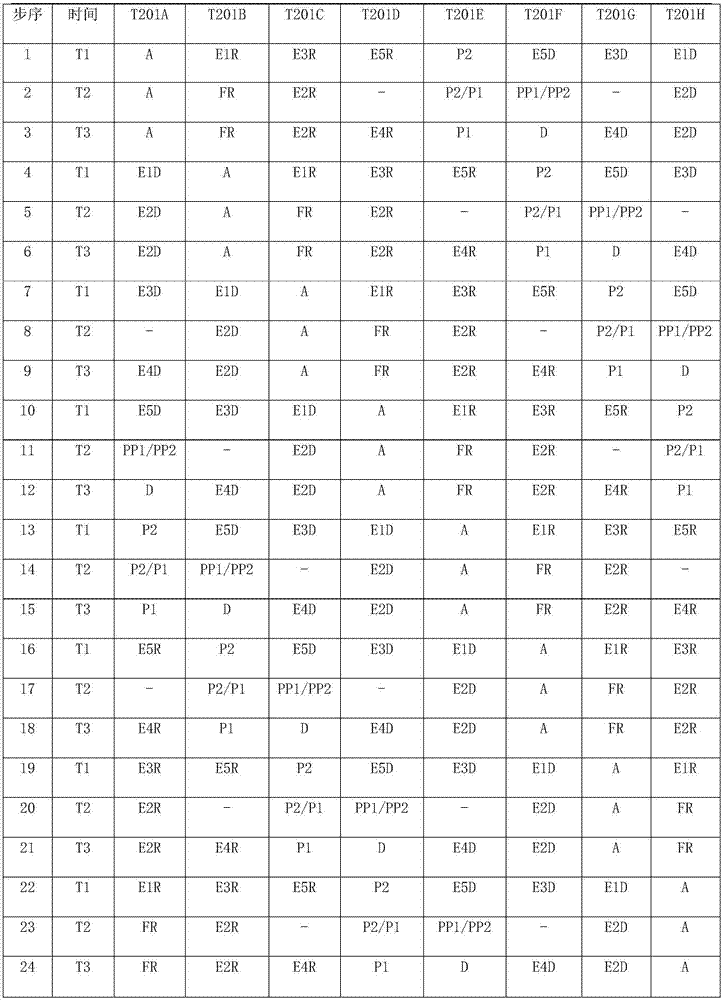

[0043] Such as figure 1 As shown, the multi-tower pressure swing adsorption grading flushing device in this embodiment includes eight adsorption towers, respectively numbered T201A, T201B, T201C, T201D, T201E, T201F, T201G and T201H.

[0044] The raw material gas end of each adsorption tower is connected with the raw material gas input pipe and the desorbed gas output pipe, the inlet of the raw gas input pipe is connected with the outlet of the raw material gas buffer tank, and the inlet of the raw material gas buffer tank is connected with the raw material gas source.

[0045] The product end of each adsorption tower is connected to the product gas output pipe, and each adsorption tower is connected to the parallel discharge circuit and the flushing circuit, and the parallel discharge circuit is respectively connected to the inlet of the high-pressure parallel discharge tank (V202A) and the inlet of the low-pressure parallel discharge tank (V202B) The flushing circuit is resp...

Embodiment 2

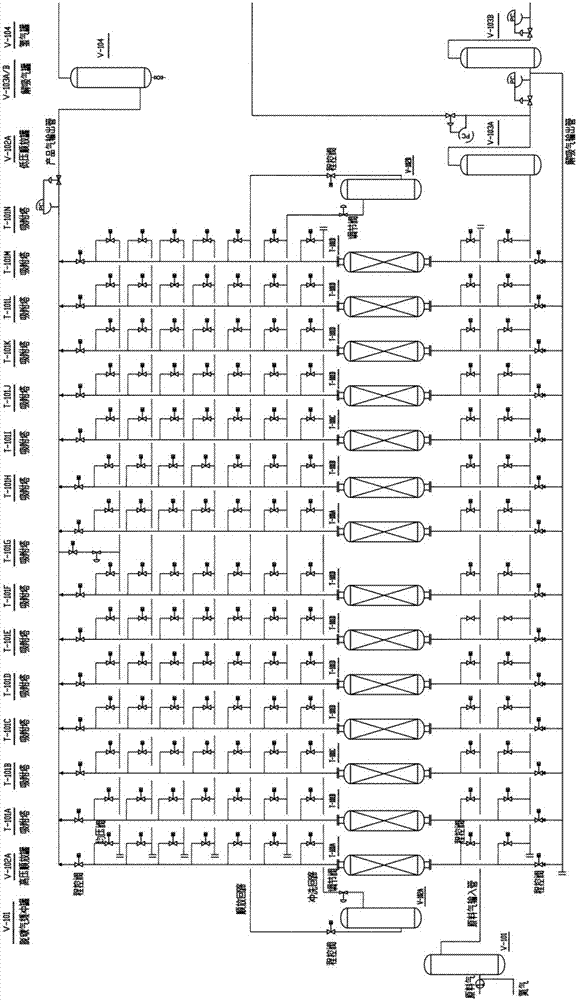

[0071] Such as image 3 As shown, the multi-tower pressure swing adsorption classification flushing device of this embodiment includes fourteen adsorption towers, respectively numbered as T101A, T101B, T101C, T101D, T101E, T101F, T101G, T101H, T101I, T101J, T101K, T101L, T101M, and T101N.

[0072] The raw gas end of each adsorption tower is connected to the raw gas input pipe and the desorbed gas output pipe, the inlet of the raw gas input pipe is connected to the outlet of the decarburization buffer tank, and the inlet of the decarburization buffer tank is respectively connected to the raw gas source and the helium source connected.

[0073] The product end of each adsorption tower is connected to the product gas output pipe, and each adsorption tower is connected to the parallel discharge circuit and the flushing circuit, and the parallel discharge circuit is respectively connected to the inlet of the high-pressure parallel discharge tank (V102A) and the inlet of the low-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com