Automatic grasping rotating type detection equipment for foreign matter in bottles

A foreign object detection and rotary technology, which is applied in measuring devices, optical testing of flaws/defects, material analysis through optical means, etc., can solve problems such as health hazards of light inspection personnel, poor repeatability and consistency of test results, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

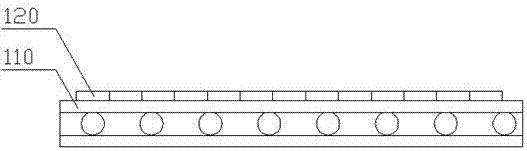

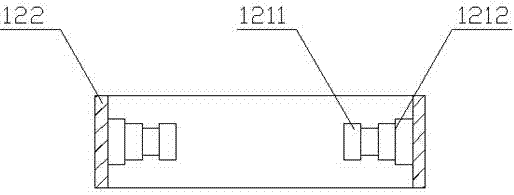

[0027] refer to Figure 1-3 , figure 1 It is a schematic diagram of the transmission mechanism of an automatic grasping and rotating foreign matter detection device in a bottle provided by the present invention; figure 2 A schematic diagram of the interior of the annular ring of an automatic grasping and rotating foreign matter detection device in a bottle provided by the present invention; image 3 It is a schematic diagram of a bottle-rotating mechanism of an automatic grasping and rotating type foreign matter detection device in a bottle provided by the present invention.

[0028] Specifically, an automatic grasping and rotating bottle foreign matter detection device includes a transmission mechanism 1, a bottle rotating mechanism 2, a detection mechanism 3, and a control processor 4. The bottle rotating mechanism 2 also includes a clamping mechanism 210, and the The detection mechanism 3 also includes a light inspection mechanism 310; the transmission mechanism 1 includ...

Embodiment 2

[0034] refer to Figure 4-6 , Figure 4 It is a schematic diagram of the bottle-rotating mechanism of the second automatic grasping and rotating foreign matter detection equipment in the bottle provided by the present invention;

[0035] Figure 5 It is a schematic diagram of the inner outer ring of the second automatic grasping and rotating type foreign matter detection device in a bottle provided by the present invention;

[0036] Figure 6 It is a structural schematic diagram of the rotating part and chuck of the second automatic grasping and rotating type foreign matter detection device in a bottle provided by the present invention.

[0037] This embodiment is basically the same as the first embodiment above, the difference is that the detection machine also includes a vibration mechanism 5, the vibration mechanism 5 is connected to the control processor 4, and the vibration mechanism 5 is arranged on the clamping mechanism 210. above.

[0038] As a preferred mode of ...

Embodiment 3

[0044] This embodiment is basically the same as the first embodiment above, the difference is that the bottle holder mechanism 120 also includes an LED light source 123 and a second image capture and analysis device 124, the LED light source 123 is arranged at the bottom of the annular ring 122, and the LED light source 123 . The second image capturing and analyzing device 124 is connected to the control processor 4 .

[0045] As a preferred form of the present invention, the second image capture and analysis device 124 is set on the side of the transmission mechanism 1, captures the image of the bottle illuminated by the LED light source 123, and judges whether the bottle has defects such as cracks and bubbles.

[0046] As a preferred mode of the present invention, there is a soft layer at the contact between the clamping rod 1211 and the bottle body.

[0047] As a preferred mode of the present invention, there is a soft layer at the contact between the chuck 211 and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com