Method for automatic tunneling for coal mine small section tunnel by use of pipe-jacking coal mine automatic tunneling equipment

A pipe jacking machine, small-section technology, applied in tunnels, mining equipment, earth-moving drilling, etc., can solve the problems of severe pick wear, high labor intensity, low safety, etc. Dangerous, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

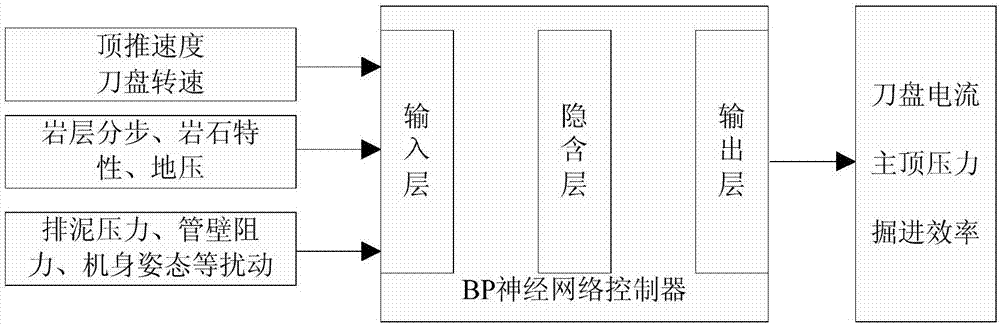

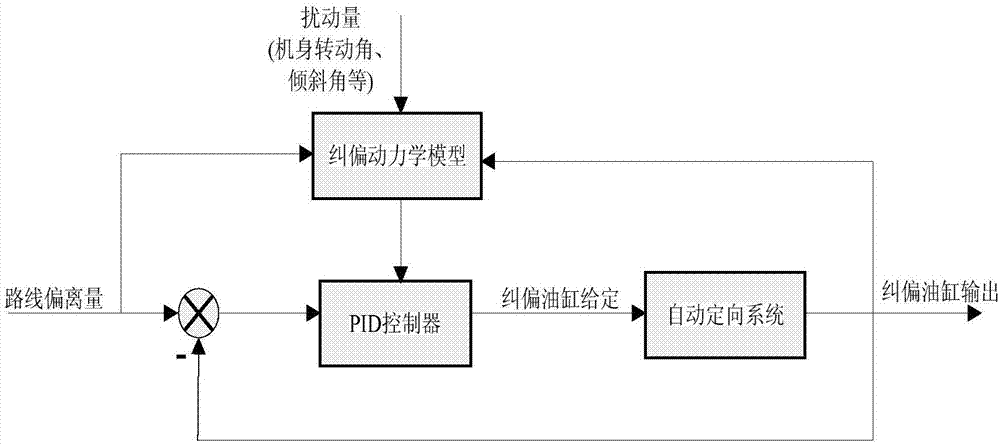

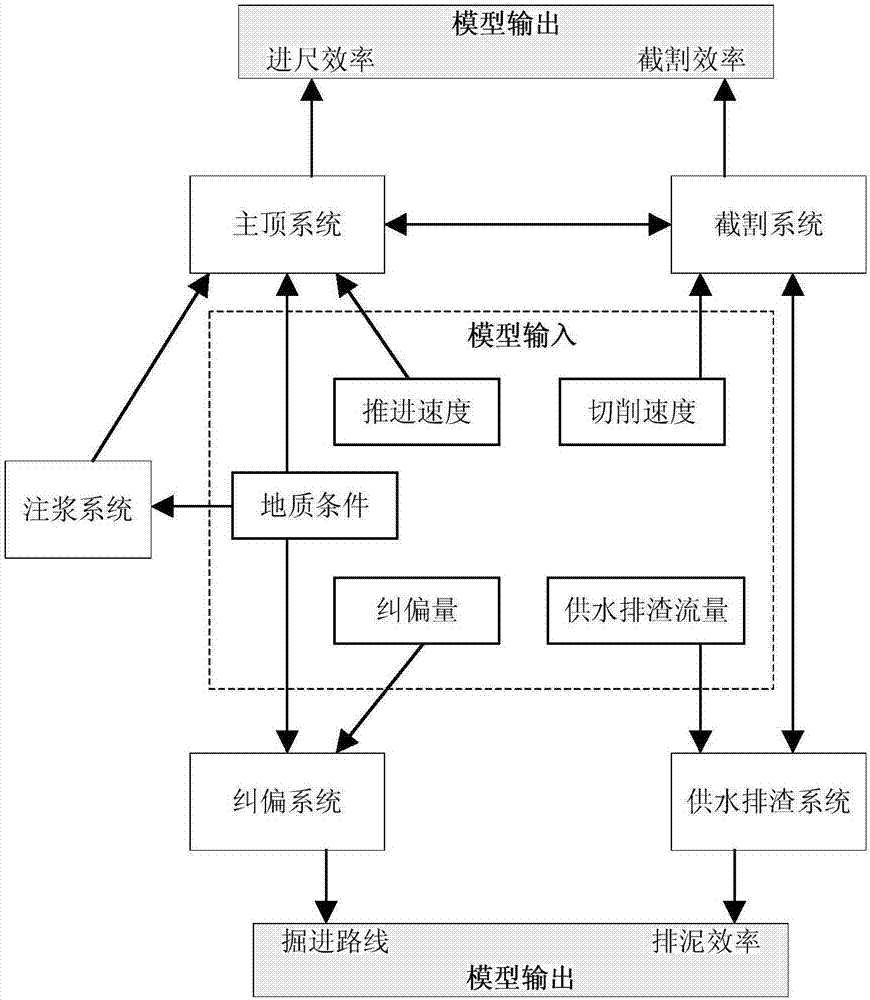

[0025] The invention provides a method for autonomous tunneling of a small-section roadway in a pipe-jacking coal mine, which is characterized in that: the intelligent construction method for a small-section roadway in a coal mine uses a pipe-jacking machine to construct a small-section roadway in a coal mine. The construction process is as follows: Firstly, relevant data such as the lithology of the roadway to be excavated are collected, and the cutter head layout of the pipe jacking machine is designed according to the physical characteristics of the roadway. A reasonable cutter head layout can make the rock cut by the cutter head moderate in size. There is a two-stage grinding system at the rear end of the cutterhead, and the cut gravel needs to pass through the two-stage grinding system to grind the size of the gravel within a reasonable range. The tool tube is on the rear side of the machine head. The outer diameter of the tool tube and the machine head is the same, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com