Carbon fiber corrosion-resistant plate

A corrosion-resistant, carbon fiber technology, used in the field of carbon fiber corrosion-resistant panels, can solve the problems of heat insulation, poor insulation and corrosion resistance, deformation of internal substrates, easy peeling, aging, etc. Aesthetically pleasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] Example 1

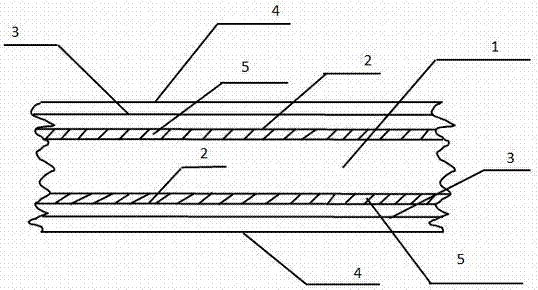

[0019] Such as figure 1 As shown, the corrosion-resistant board includes a base, a corrosion-resistant coating, and a baking varnish layer. The base is formed by stacking several layers of composite boards, and the composite board is a pine board with a hard material layer sandwiched in the center.

[0020] An epoxy resin layer and a glass fiber layer are wrapped on the outside of the substrate, and the glass fiber layer is a mesh glass fiber cloth. The exterior of the substrate and the epoxy resin layer are filled with a carbon fiber layer. In this embodiment, a pitch-based carbon fiber layer is used. The outer surface of the glass fiber layer is coated with a 10um-25um baking varnish layer, and the baking varnish layer is raw lacquer , Phenolic resin paint, inorganic zinc-rich paint.

[0021] Since the substrate in the present invention is a pine board sandwiched with a hard material layer, the hard materials used in this embodiment are thin and strong boards s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com