Linear high-energy plastic and preparation method thereof

A high-energy adhesive and thread-like technology, which can be used in other household appliances, household components, applications, etc., can solve the problems of difficult cutting of sheets, defective products, and inability to bond fiber composite materials, etc., to achieve both flexibility and torque, The effect of being convenient for industrial application and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Follow the steps below to prepare linear high-energy glue:

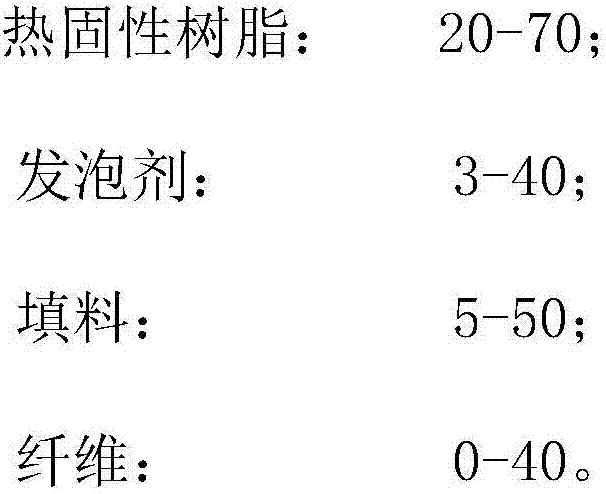

[0048] 1) Mix the following components by weight to obtain the compound:

[0049]

[0050] 2) Heat the mixture to 50°C to melt it, and its viscosity is 100,000 mPa·s;

[0051]3) Dip the cotton rope into the melted mixture, then take it out, and after cooling to room temperature, the material is solidified and formed into a linear high-energy adhesive.

[0052] The obtained linear high-energy adhesive has a diameter of 5 mm, and the heat-expandable composite resin material accounts for 10% of the total weight of the linear high-energy adhesive after molding.

[0053] The linear high-energy glue obtained according to the above method is used in the molding of badminton rackets, and the obtained appearance is plump without air bubbles in the middle, taking into account the flexibility and torsion of the racket.

Embodiment 2

[0055] Follow the steps below to prepare linear high-energy glue:

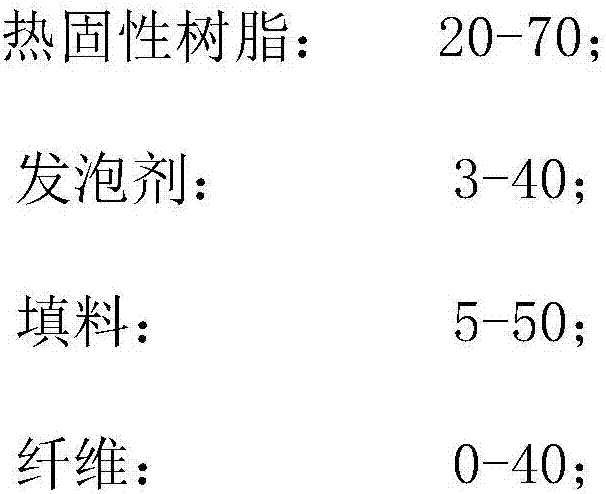

[0056] 1) Mix the following components by weight to obtain the compound:

[0057] Thermosetting resin: 70;

[0058] Foaming agent: 40;

[0059] Filler: 50;

[0060] 2) Heat the mixture to 90°C to melt it, and its viscosity is 1000mPa·s;

[0061] 3) Dip the hemp rope into the melted mixture, then take it out, and after cooling to room temperature, the material is solidified and formed into a linear high-energy adhesive.

[0062] The obtained linear high-energy adhesive has a diameter of 7mm, and the heat-expandable composite resin material accounts for 40% of the total weight of the linear high-energy adhesive after molding.

[0063] The linear high-energy glue obtained according to the above method is used in the molding of badminton rackets, and the obtained appearance is plump without air bubbles in the middle, taking into account the flexibility and torsion of the racket.

Embodiment 3

[0065] Follow the steps below to prepare linear high-energy glue:

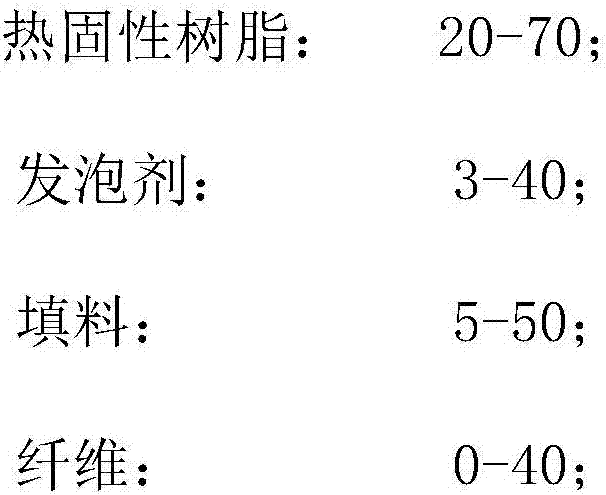

[0066] 1) Mix the following components by weight to obtain the compound:

[0067]

[0068] 2) Heat the mixture to 60°C to melt it, and its viscosity is 70,000 mPa·s;

[0069] 3) Dip the hemp rope into the melted mixture, then take it out, and after cooling to room temperature, the material is solidified and formed into a linear high-energy adhesive.

[0070] The obtained linear high-energy adhesive has a diameter of 10mm, and the heat-expandable composite resin material accounts for 70% of the total weight of the linear high-energy adhesive after molding.

[0071] The linear high-energy glue obtained according to the above method is used in the molding of badminton rackets, and the obtained appearance is plump without air bubbles in the middle, taking into account the flexibility and torsion of the racket.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com