Method for synthesizing sulfenamide-like accelerator TBBS by using solvent purification method rubber accelerator M

A technology of rubber accelerator and sulfenamide, which is applied in the field of rubber accelerator M to synthesize sulfenamide accelerator TBBS by solvent purification method, so as to reduce the generation of dried sludge, stabilize various indicators, and realize clean and civilized production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

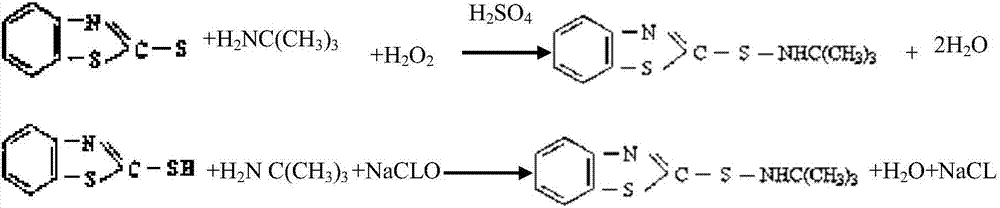

Method used

Image

Examples

Embodiment

[0029] 1. Determine the best production process conditions through the following experiments:

[0030] (1) The influence of raw material ratio on product quality and yield

[0031] When the reaction temperature is controlled at 40-60°C and the reaction time is 2.0-3.0 hours, the influence of the raw material ratio on the product quality and yield is tested

[0032]

[0033] Note: The dual oxidant system is used, and the amount of sodium hypochlorite used is subject to the end point detection.

[0034] According to the analysis of experimental data, when the molar ratio of M and tert-butylamine is 1:1.5, the appearance of the product is light yellow, and the yield and melting point are all on the low side. With the decrease of the molar ratio of M and tert-butylamine, the appearance, yield and melting point are all improved. When the tert-butylamine is too much, because the product is dissolved in the tert-butylamine solution, the yield is reduced, and the post-treatment re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com