Electronic grade polysilicon reduction furnace and production method of polysilicon

A polysilicon and reduction furnace technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high proportion of popcorn material and high energy consumption, achieve uniform gas and temperature distribution, reduce radiant heat, reduce The effect of restoring power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

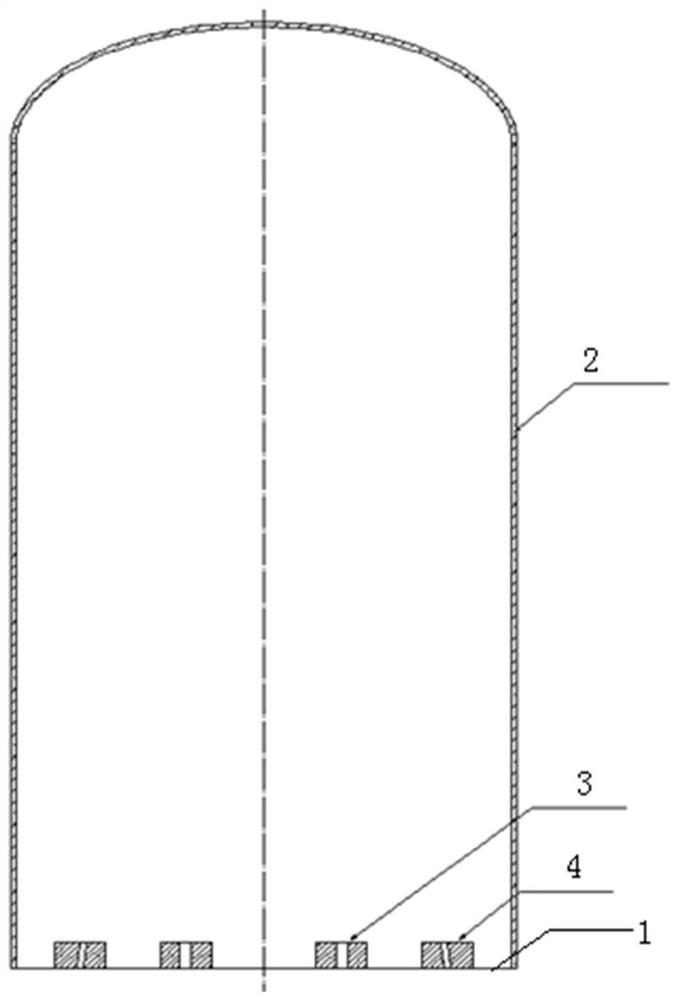

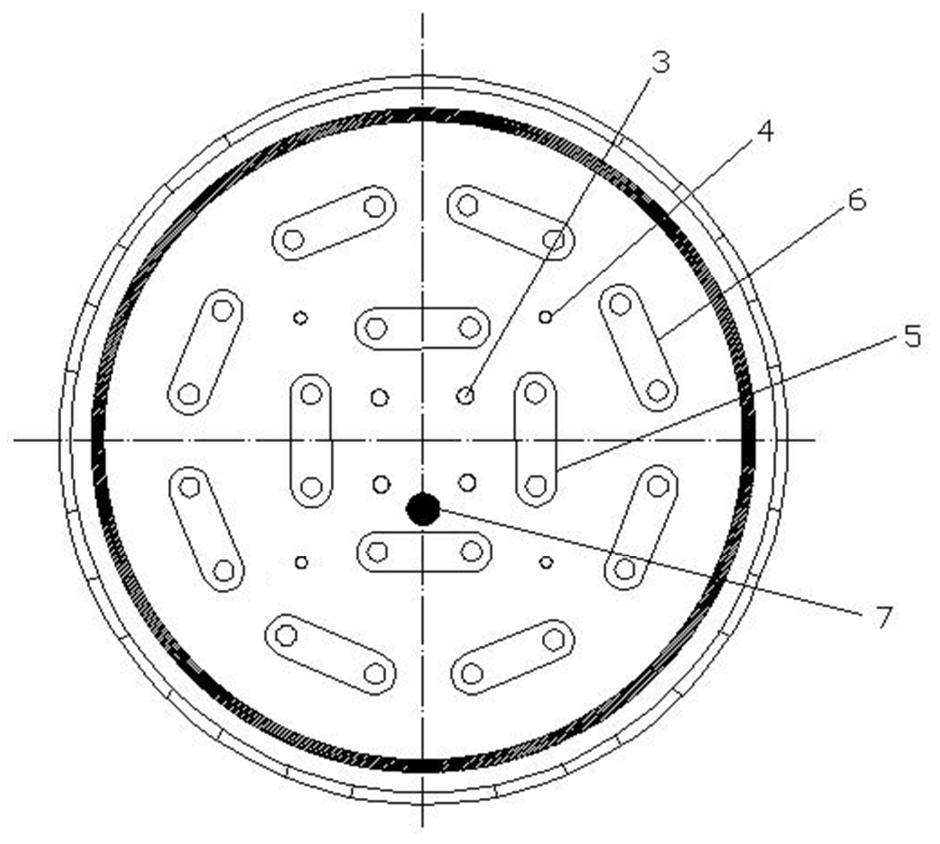

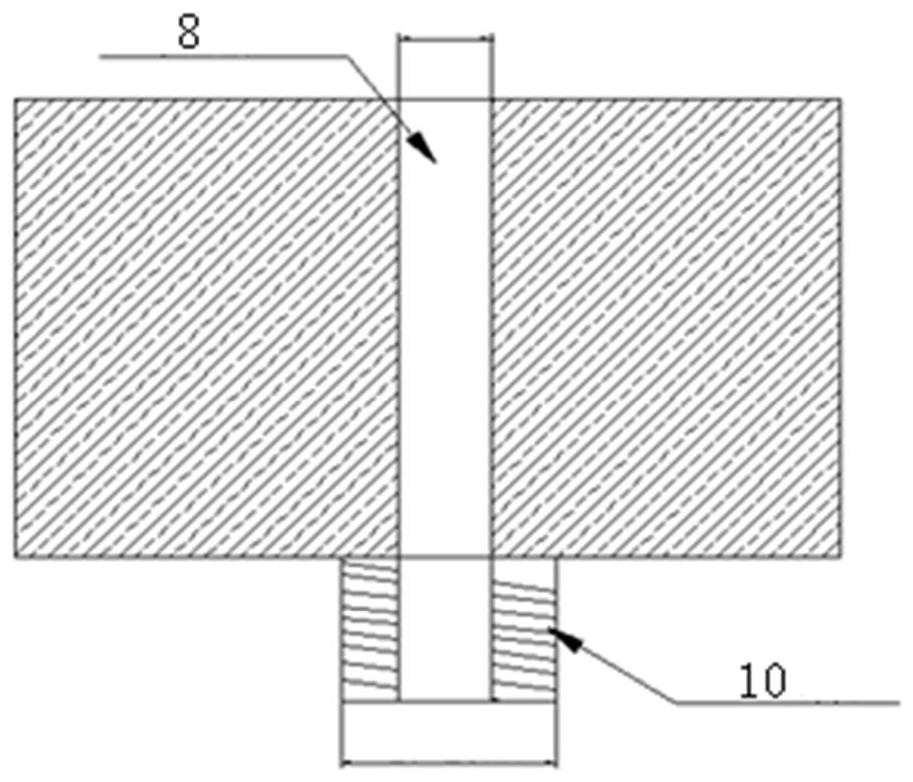

[0046] see Figure 1-7 , where 1 is the chassis, 2 is the furnace body of the reduction furnace, 3 is the inner layer nozzle, 4 is the outer layer nozzle, 5 is the inner layer electrode, 6 is the outer layer electrode, 7 is the exhaust port, and 8 is the gas phase of the inner layer nozzle Channel, 9 is the gas phase channel of the outer layer nozzle, and 10 is a thread.

[0047] The electronic-grade polysilicon reduction furnace includes a chassis 1 and a bell-shaped furnace body 2 covering the chassis. The chassis is provided with multiple pairs of electrodes, multiple nozzles and an exhaust port. The chassis is equipped with 12 pairs of electrodes, and the electrodes are arranged in a 4+8 arrangement, that is, the inner electrode 5 and the outer electrode 6, the inner layer is evenly distributed 4 pairs of electrodes, and the outer layer is evenly distributed 8 pairs of electrodes; the nozzle adopts 4+4 Arrangement mode, that is, inner layer nozzles 3 and outer layer nozzl...

Embodiment 2

[0052] Electronic grade polysilicon reduction furnace structure is the same as embodiment 1, the difference is the chassis (see Figure 8 ) is equipped with 24 pairs of electrodes, and the electrodes adopt a 4+8+12 arrangement, that is, 4 pairs of electrodes are evenly distributed in the inner layer, 8 pairs of electrodes are evenly distributed in the middle layer, and 12 pairs of electrodes are evenly distributed in the outer layer; the nozzle adopts 4+4+8 The arrangement method, that is, 4 nozzles are evenly distributed in the inner layer, 4 nozzles are evenly distributed in the middle layer, and 8 nozzles are evenly distributed in the outer layer. The outlet direction of the gas phase channel of the inner layer nozzle is perpendicular to the direction of the chassis, and the outlet direction of the gas phase channel of the middle layer nozzle and the outer layer nozzle faces the center line of the reduction furnace and forms an included angle of 75-85 degrees with the direct...

Embodiment 3

[0054] (1) In the early stage of silicon rod growth: the molar ratio of hydrogen and trichlorosilane in the raw material gas injected through the nozzle is 6:1, the surface temperature of the silicon rod is 1070°C, and the growth time of the silicon rod is 0h1 ≤30h, the flow rate of feed gas is 80m / s;

[0055] (2) In the middle stage of silicon rod growth: the molar ratio of hydrogen and trichlorosilane in the raw material gas injected through the nozzle is 5:1, the surface temperature of the silicon rod is 1020°C, and the growth time of the silicon rod is 30h2 ≤165h, the flow rate of feed gas is 170m / s;

[0056] (3) In the late stage of silicon rod growth: the molar ratio of hydrogen and trichlorosilane in the raw material gas injected through the nozzle is 5:1, the surface temperature of the silicon rod is 910°C, and the growth time of the silicon rod is 165h3 ≤170h, the flow rate of feed gas is 60m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com