Rotary liquid fertilizer filling device

A liquid fertilizer and filling device technology, which is applied in liquid bottling, liquid treatment, packaging, etc., can solve the problems of liquid fertilizer waste, liquid fertilizer splashing, large footprint, etc., achieve simple structure and reduce foam generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

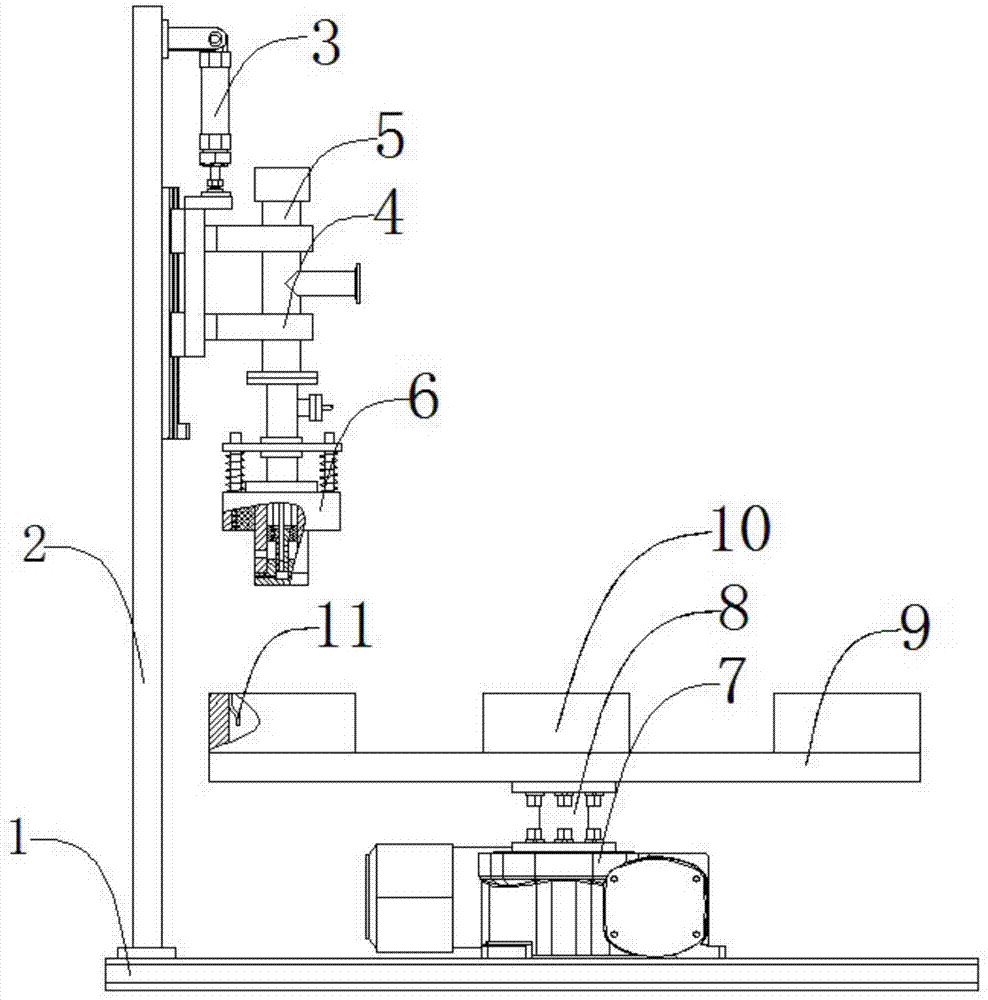

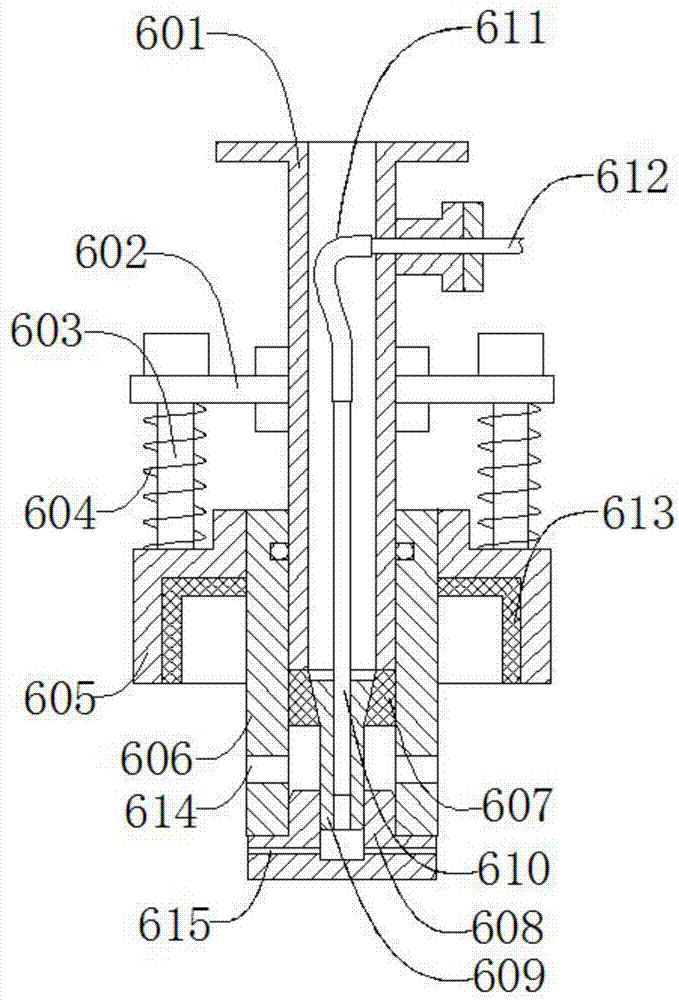

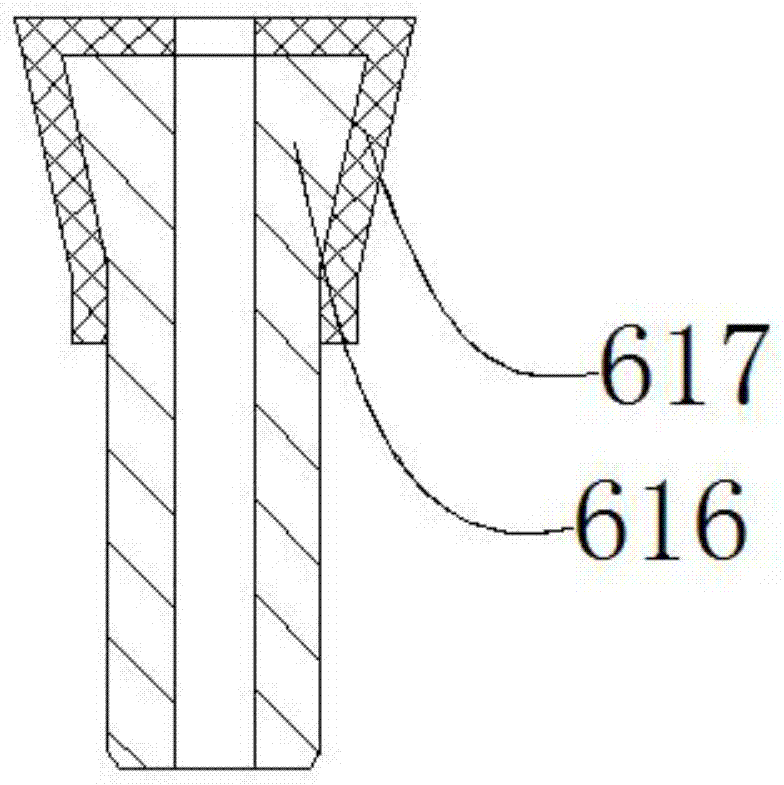

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a rotary liquid fertilizer filling device includes a base 1, a stand 2, a cylinder 3, a sliding seat 4, a liquid inlet main pipe 5, a filling head 6, a divider 7, a rotating shaft 8, a turntable 9, along the The turntable 9 is evenly distributed with no less than 2 placement seats 10, and 3 pieces of shrapnel 11 are evenly distributed along the placement seat 10. The described stand 2 is located on the left side of the upper end of the base 1, and the described stand 2 is threadedly connected with the base 1, the cylinder 3 is located on the right side of the stand 2, the cylinder 3 is hinged to the stand 2, the slide 4 is located at the lower end of the cylinder 3 and on the right side of the stand 2, the The sliding seat 4 is threadedly connected with the cylinder 3 and is slidingly connected with the stand 2. The liquid inlet main pipe 5 is located on the right side of the sliding seat 4. The liquid inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com