Stamping part plate guide support with guide and sensing dual functions

A dual-function, stamping technology, applied in the field of material guiding and positioning devices, can solve the problems of guiding, sensing mechanism design and installation difficulty, and difficulty in finding a reasonable installation position of the sensor, etc., to achieve the effect of solving the narrow space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

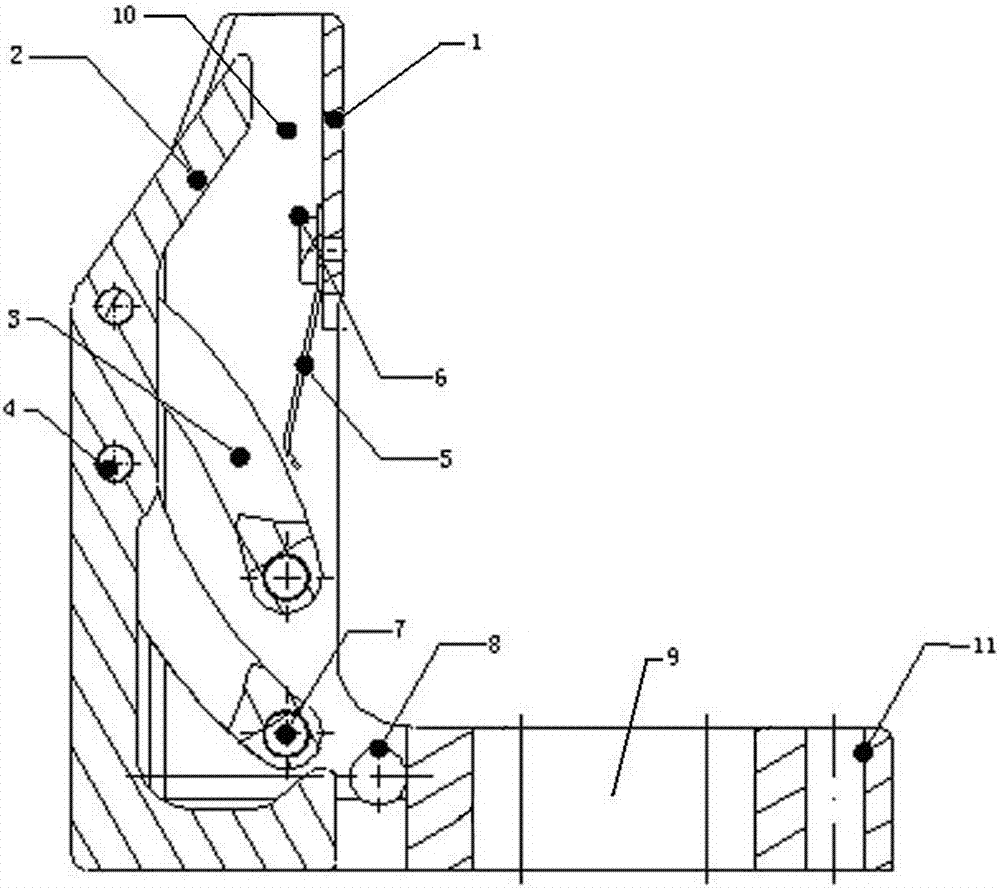

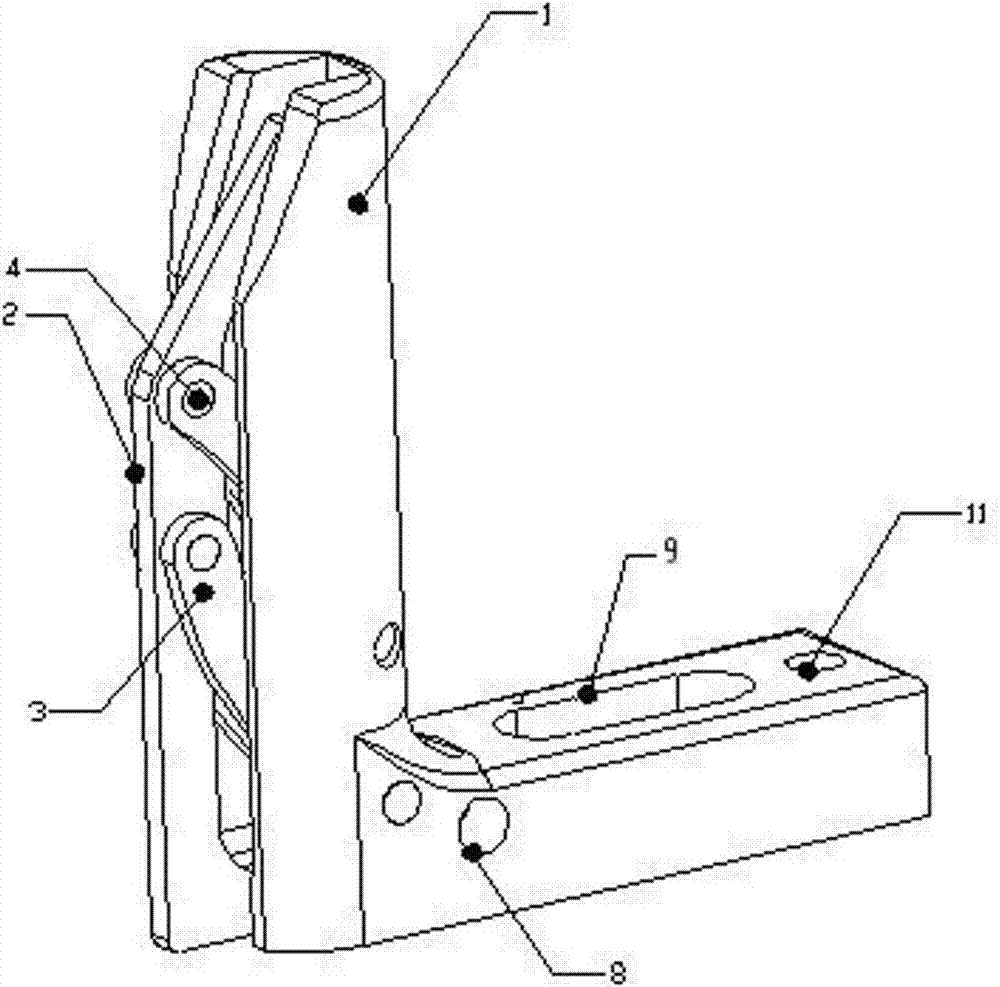

[0010] refer to figure 2 , image 3 , the guiding frame of the present invention includes a column 1, a base 8, a bar-shaped assembly screw hole 9 is arranged on the base 8, a vertical groove 10 is arranged on the front side of the column 1 (the side facing the sheet), and the vertical groove 10 is assembled Correct guide plate 2, the guide guide plate 2 has the front part of the vertical guide front exposed outside the groove, the guide guide plate 2 is L-shaped formed by the vertical part and the horizontal part of the lower end of the vertical part, between the guide plate 2 and the column 1 Two groups of parallel connecting rods 3 are articulated through the hinge shaft 4, each group of two connecting rods are oppositely arranged on both sides of the guide plate 2, the distance between the two hinge shaft holes on the connecting rod 3 is the same, and the two connecting rods on the guide plate 2 have the same distance. The distance of two hinge shaft holes is identical w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com